Chemical wastewater filtering and purifying device

A technology for filtration and purification of chemical wastewater, applied in filtration treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of poor filtration effect and difficulty in popularization and application, and achieve the effect of ensuring the quality of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

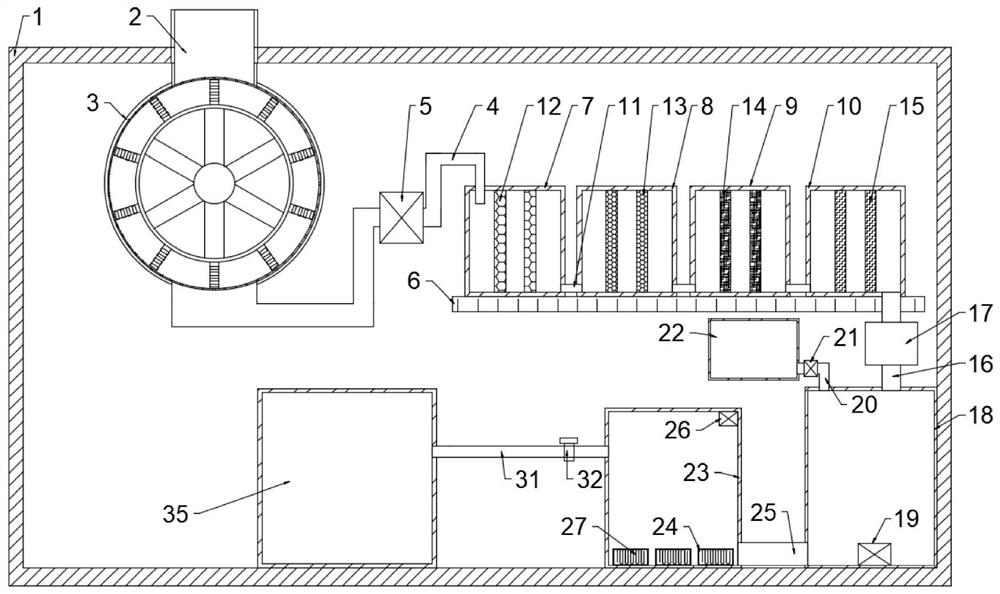

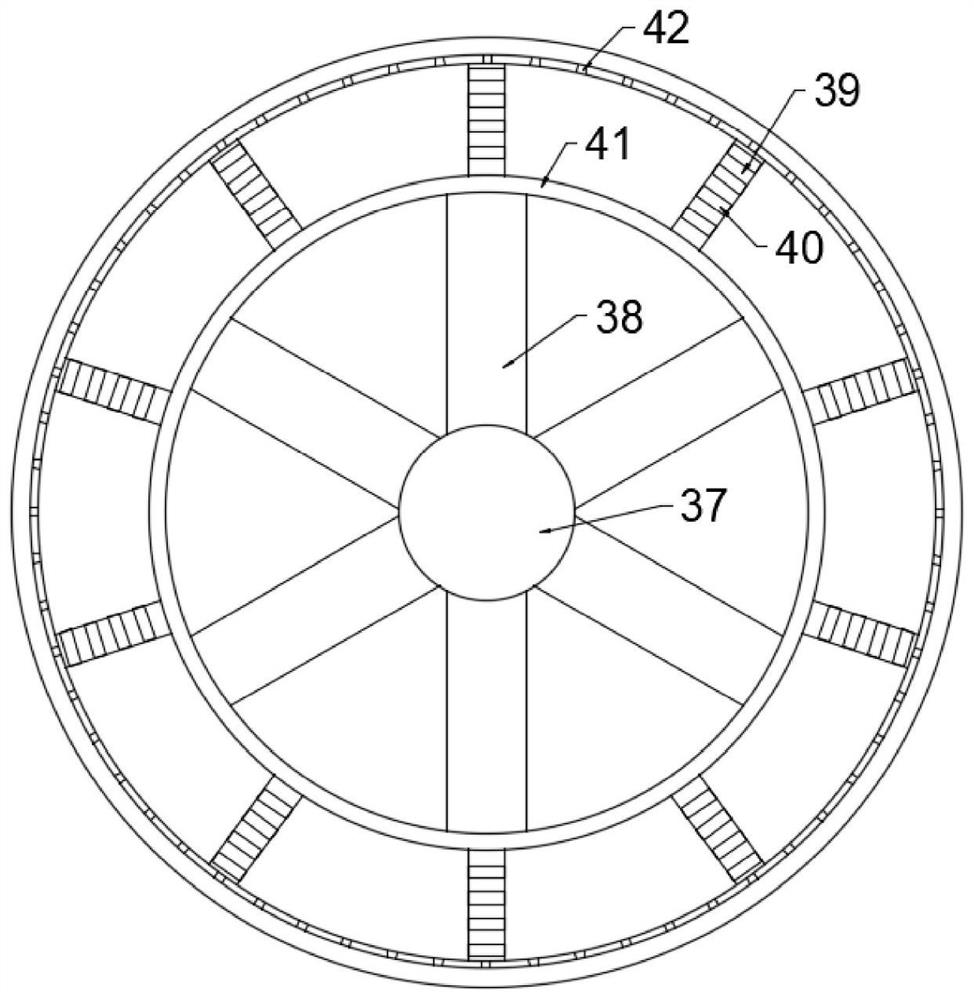

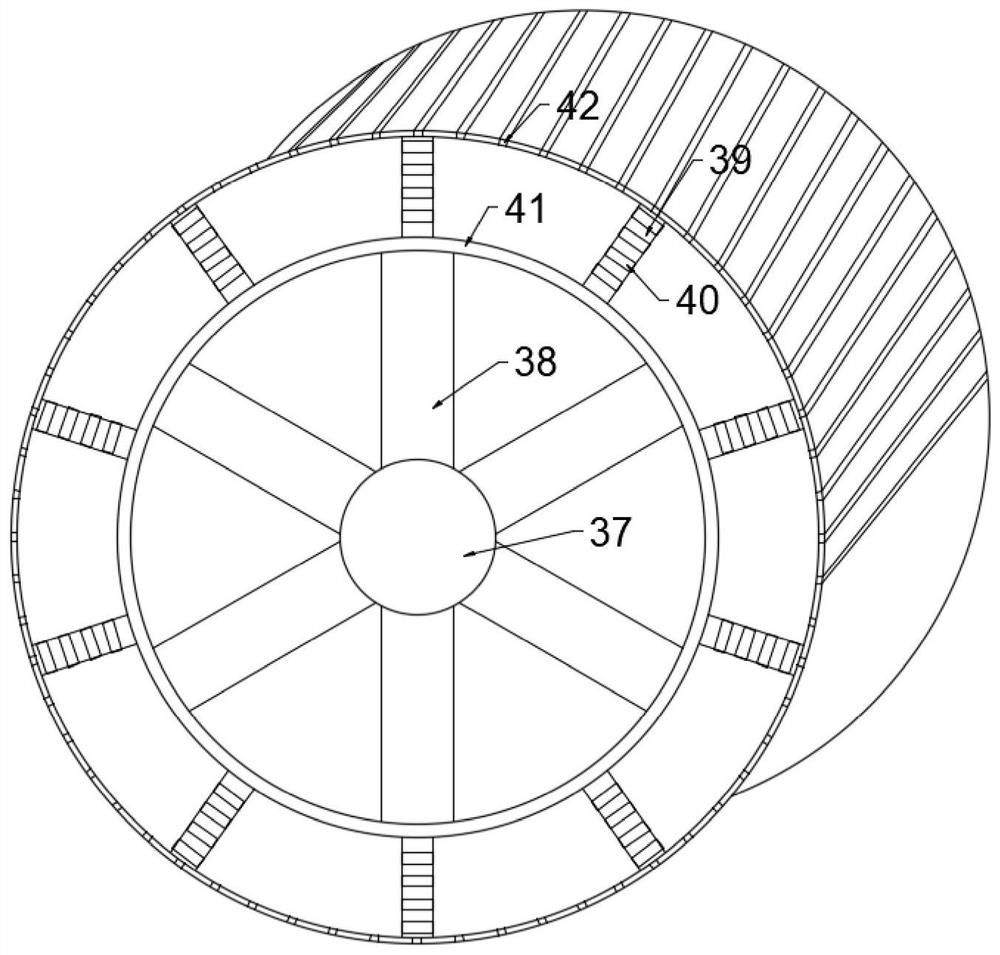

[0031] see Figure 1 ~ Figure 4, a chemical wastewater filtration and purification device, including a device box 1, the device box 1 is provided with a liquid inlet 2, the liquid inlet 2 penetrates the device box 1, and the liquid inlet 2 is connected to a filter drum 3. A water inlet pipe 4 is provided below the filter drum 3, and the end of the water inlet pipe 4 away from the filter drum 3 is connected to the first filter box 7, and the first filter box 7 is connected to the first filter box 7. The water pipe 11, the end of the water pipe 11 away from the first filter box 7 runs through the second filter box 8, the second filter box 8 is connected to the water pipe 11, and the water pipe 11 is far away from the second filter box 8 One end runs through the third filter box 9, the third filter box 9 is connected to the water pipe 11, and the end of the water pipe 11 away from the third filter box 9 runs through the fourth filter box 10, the fourth filter box 10 is provided ...

Embodiment 2

[0039] see Figure 1 to Figure 5 , a chemical wastewater filtration and purification device, including a device box 1, and also includes a steam inlet pipe 28, a one-way valve 29, a condensation box 30, a steam outlet pipe 33, a second electric control valve 34 and a control center 36, the device The tank 1 is provided with a liquid inlet 2, the liquid inlet 2 runs through the device cabinet 1, the liquid inlet 2 is connected to the filter drum 3, and a water inlet pipe 4 is arranged below the filter drum 3, and the water inlet pipe 4 The end away from the filter drum 3 is connected to the first filter box 7, the first filter box 7, the first filter box 7 is connected to the water pipe 11, and the end of the water pipe 11 away from the first filter box 7 runs through The second filter box 8, the second filter box 8 is connected to the water pipe 11, and the end of the water pipe 11 away from the second filter box 8 runs through the third filter box 9, and the third filter box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com