Differential pressure indicator for controlling temperature by using liquid metal

A technology for controlling temperature and liquid metal. It is used in instruments, alarms, springs/shock absorbers, etc. It can solve the problems of false alarms, high rejection rate, time-consuming and labor-intensive, etc., to facilitate temperature control, avoid false alarms, and be easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

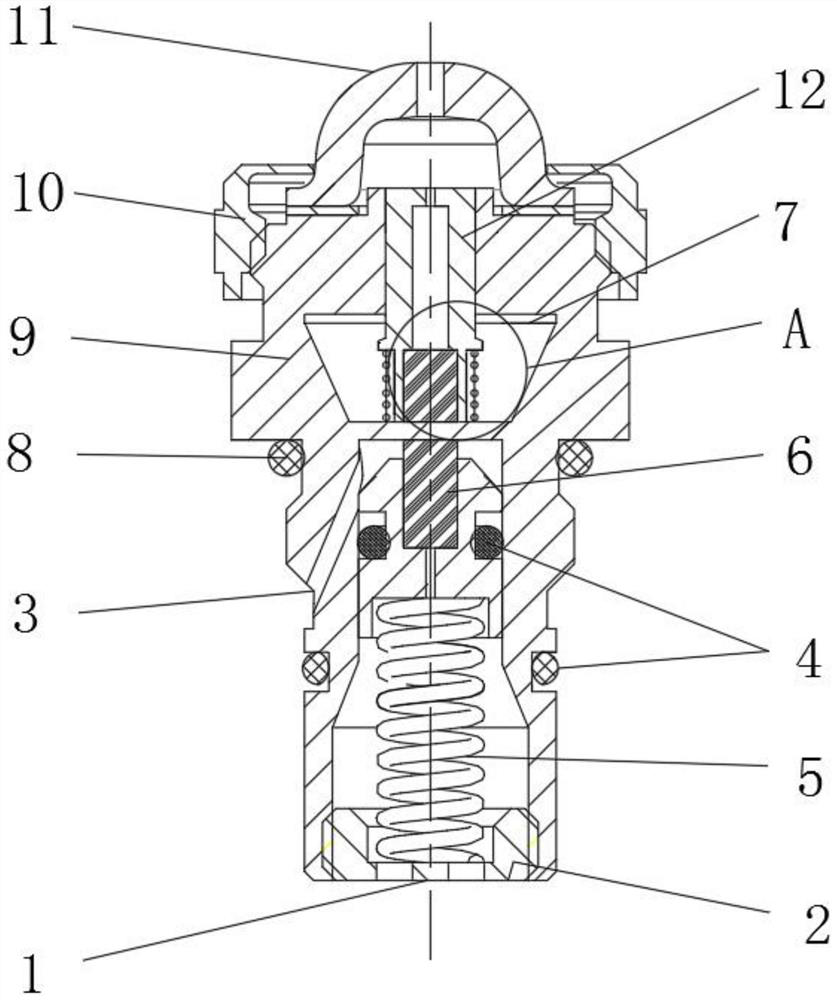

Embodiment 1

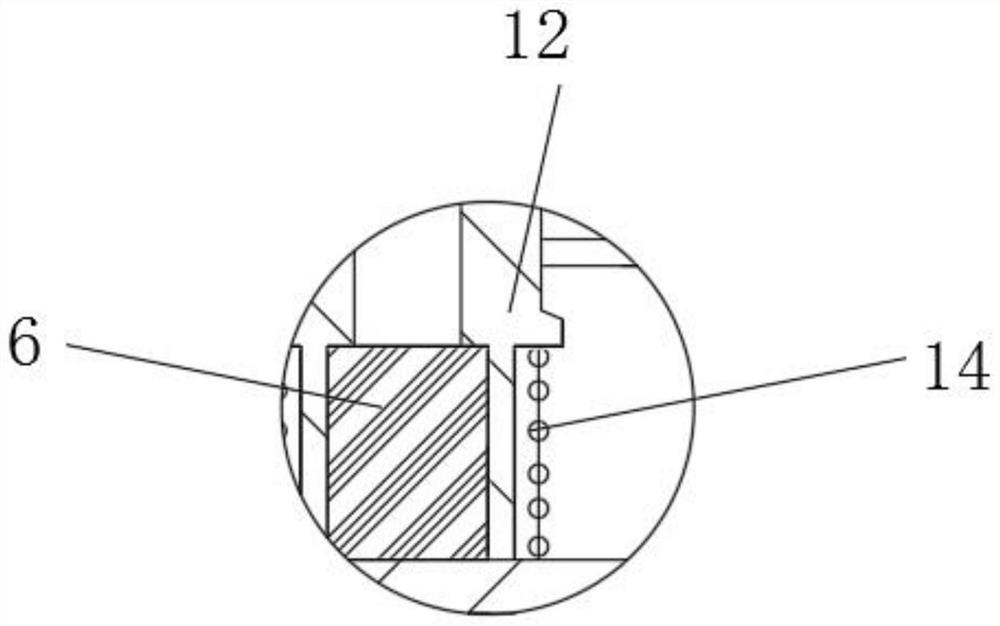

[0025] A differential pressure transmitter that uses liquid metal to control temperature, such as Figure 1-2 As shown, it includes a housing 9, the lower part of the housing 9 and the middle part of the lower end of the housing 9 are respectively provided with a filter oil inlet 3 and a filter oil outlet 1, and the lower end of the housing 9 is fixedly installed with a spring seat 2, a spring seat 2 The lower spring 5 is fixedly installed on the upper part, the lower magnetic steel assembly 6 is fixedly installed on the upper end of the lower spring 5, the upper cavity 7 is opened inside the housing 9, the upper magnetic steel assembly 12 is arranged inside the upper cavity 7, and the upper end of the housing 9 is arranged There is a nut 10, the middle part of the nut 10 is provided with a transparent cover 11, the middle part of the lower magnetic steel assembly 6 and the lower part of the outer surface of the housing 9 are provided with a No. 1 sealing ring 4, and the middle...

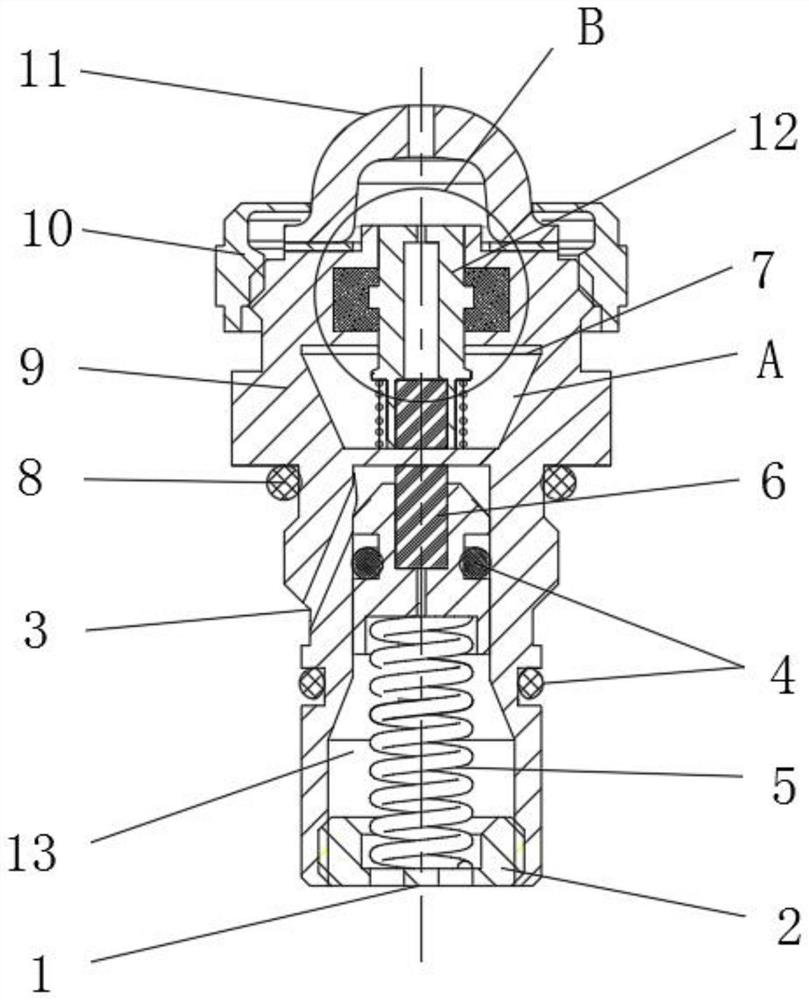

Embodiment 2

[0029] A differential pressure transmitter that uses liquid metal to control temperature, such as Figure 3-4 As shown, it includes a housing 9, the lower part of the housing 9 and the middle part of the lower end of the housing 9 are respectively provided with a filter oil inlet 3 and a filter oil outlet 1, and the lower end of the housing 9 is fixedly installed with a spring seat 2, a spring seat 2 The lower spring 5 is fixedly installed on the upper part, the lower magnetic steel assembly 6 is fixedly installed on the upper end of the lower spring 5, the upper cavity 7 is opened inside the housing 9, the upper magnetic steel assembly 12 is arranged inside the upper cavity 7, and the upper end of the housing 9 is arranged There is a nut 10, the middle part of the nut 10 is provided with a transparent cover 11, the middle part of the lower magnetic steel assembly 6 and the lower part of the outer surface of the housing 9 are provided with a No. 1 sealing ring 4, and the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com