Linear motor

A linear motor, integrated technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of cumbersome assembly process and complex damping structure, and achieve the effect of improving the damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

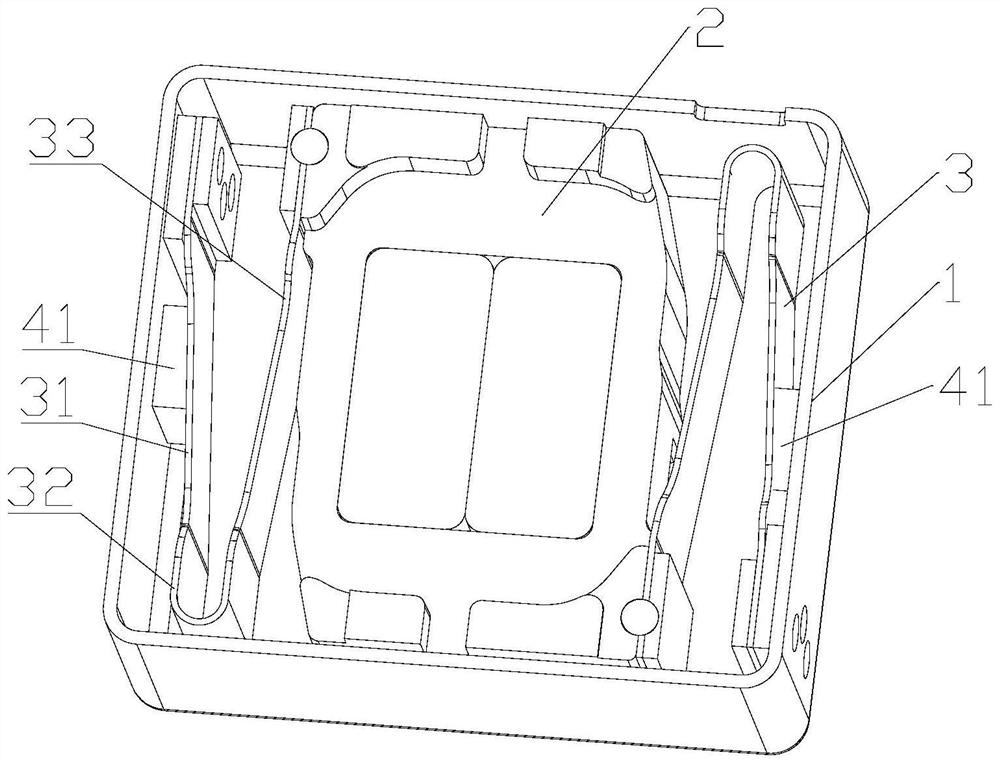

[0031] Such as figure 1 As shown, this embodiment provides a linear motor, including a casing 1, a vibration assembly 2, and a damper assembly; the vibration assembly 2 is located in the casing 1; there are gaps between the left and right sides of the vibration assembly 2 and the inner wall of the casing 1; Damping components are respectively fixed in the gaps on the left and right sides of the vibrating component 2; the damping component includes a V-shaped spring 3; the opening direction of the V-shaped spring 3 on the left and right sides of the vibrating component 2 is set in the opposite direction or in the same direction; the V-shaped spring 3 includes a corner end 32 and the first connecting arm 31, the second connecting arm 33; the end of the first connecting arm 31 is fixed to the inner wall of the casing 1, the end of the second connecting arm 33 is fixed to the outer wall of the vibration assembly 2, and the corner end 32 There is a gap between the outer wall and th...

Embodiment 2

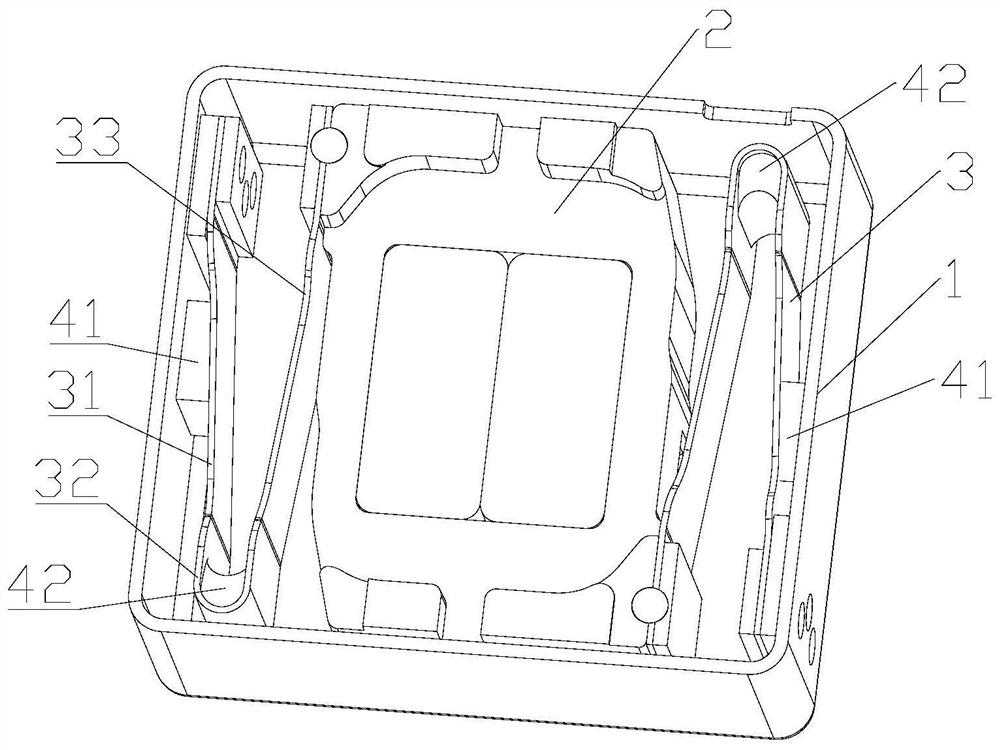

[0035] Such as figure 2 As shown, on the basis of Embodiment 1, a second damping member 42 is fixed inside the corner end 32, and in this embodiment, the second damping member 42 is made of damping glue.

Embodiment 3

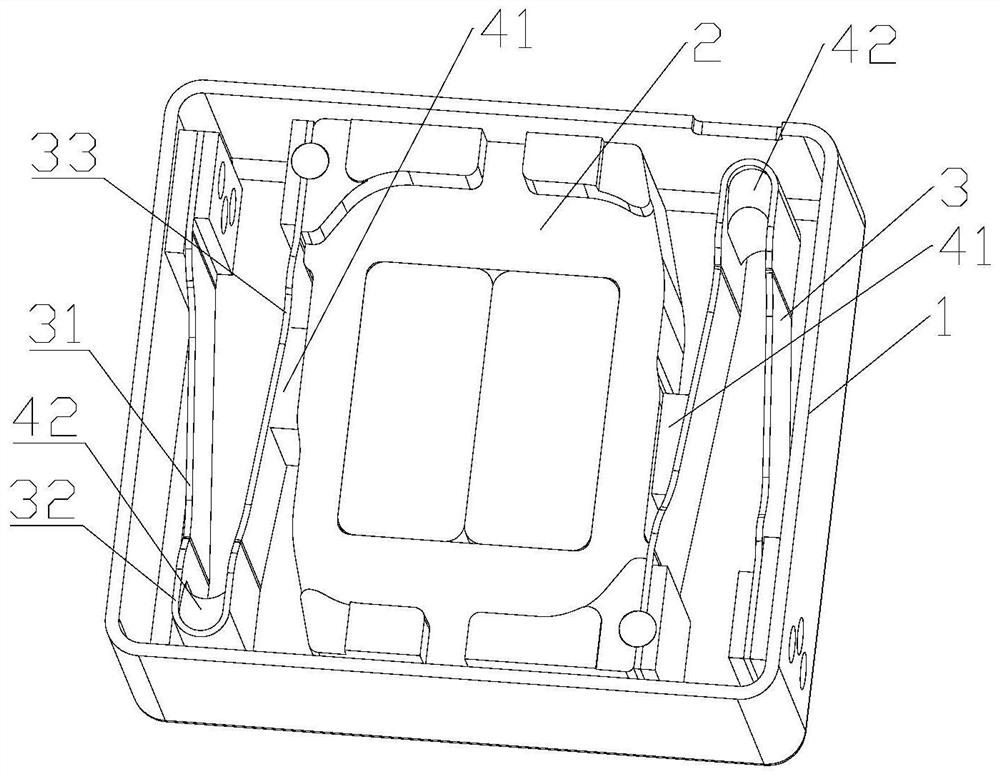

[0037] Such as image 3 As shown, compared with Embodiment 2, the first damping member 41 in this embodiment is fixed outside the second connecting arm 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com