Vegetable seed sowing plough

A kind of seeding machine and seed technology, which is applied in the direction of planter parts, seeding, fertilizing devices, etc., can solve the problem of wasting users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

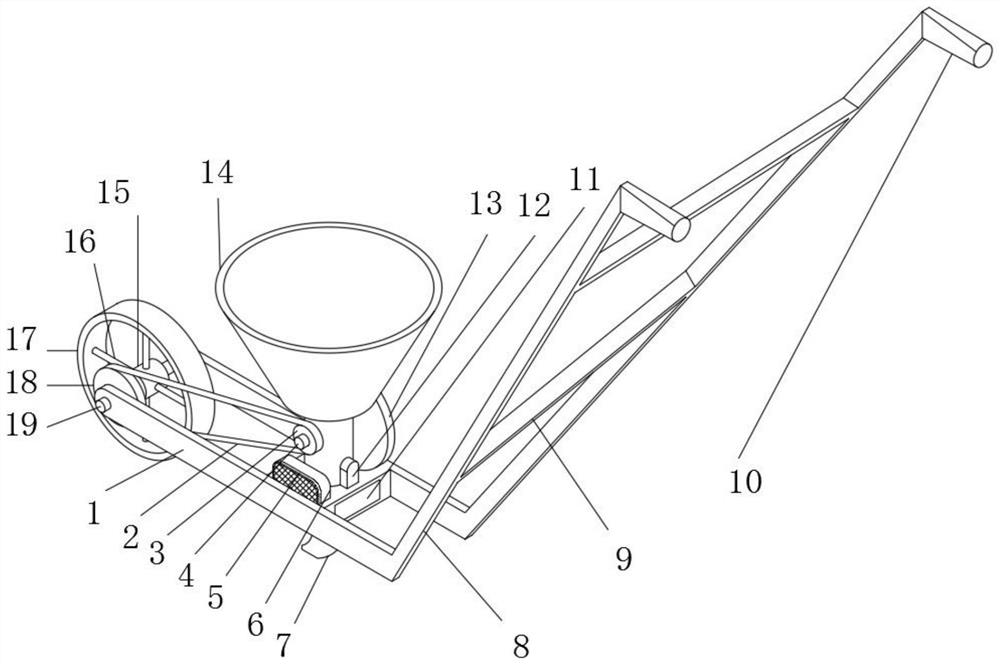

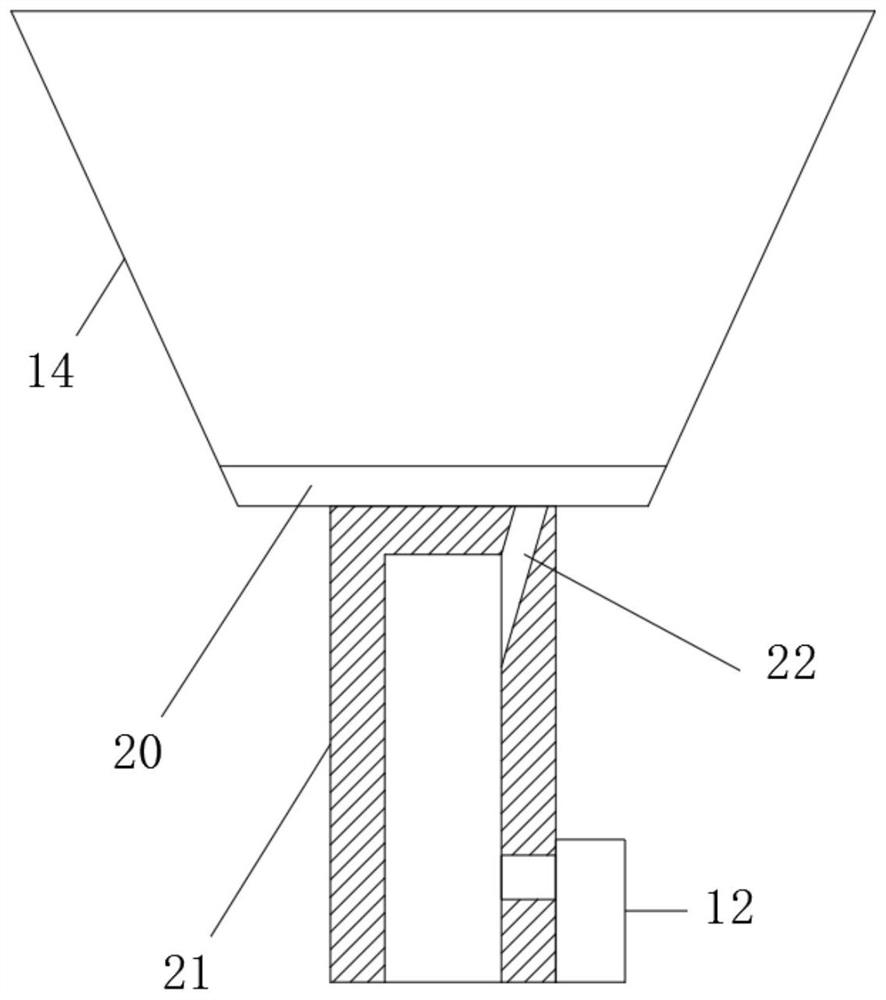

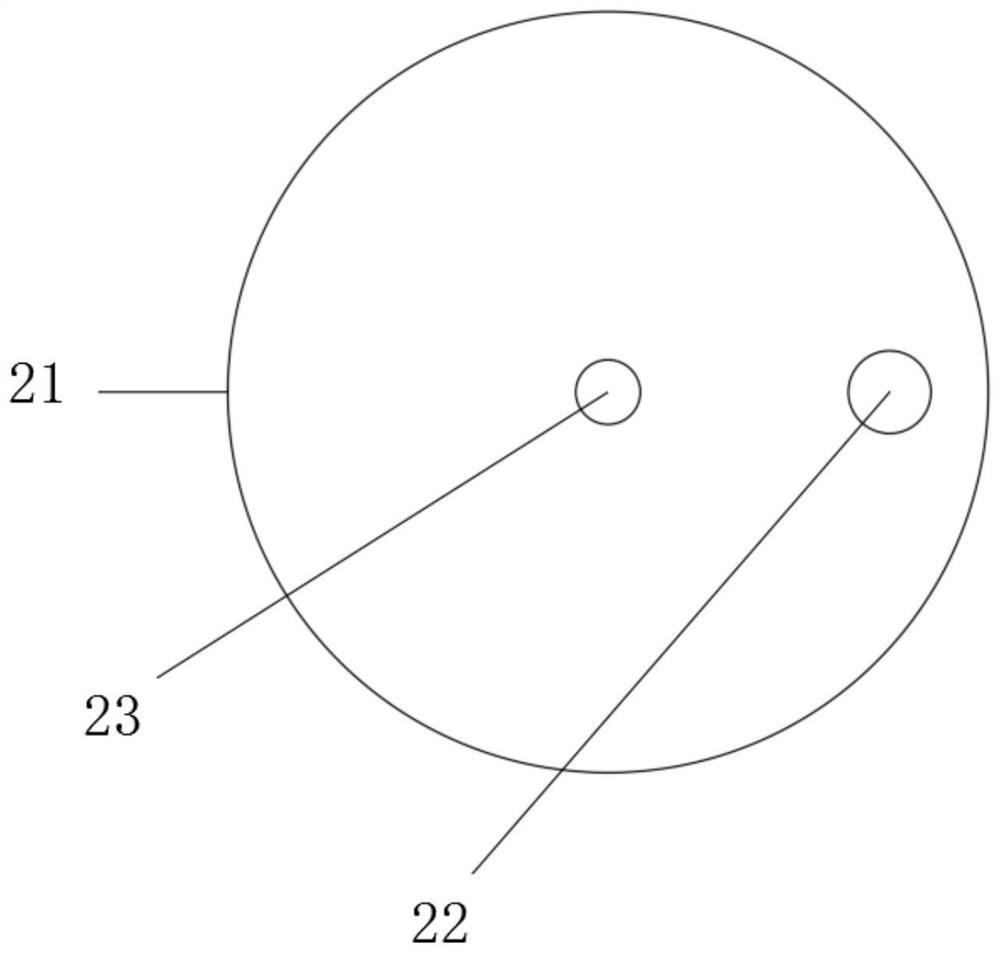

[0028] see figure 1 , 2 , 5, a vegetable seed sowing machine, comprising main beam 1, chain 2, driven gear 3, driven shaft 4, turntable gear 13, seed bucket 14, wheel drum 15, wheel spoke 16, wheel 17, driving Gear 18, wheel shaft 19, turntable 20, seed standpipe 21, threaded counterbore 23, movable bolt 25 and circular rack 26, wheel shaft 19 is arranged in the middle of the left end of main beam 1, and wheel shaft 19 is sheathed on the main beam 1 through bearing, A wheel drum 15 is arranged in the middle of the wheel shaft 19, and the wheel drum 15 is sleeved on the wheel shaft 19 through a bearing. The outer side of the wheel drum 15 is evenly provided with four wheel spokes 16, and the wheel spokes 16 are all fixed on the wheel drum 15 by welding. One end is provided with a wheel 17, the wheel 17 is fixed on the spoke 16 by welding, the front of the wheel drum 15 is provided with a driving gear 18, and the driving gear 18 is fixed on the wheel shaft 19 through a pin key;...

Embodiment 2

[0030] see figure 1 , 2, a vegetable seed sowing machine, comprising a main beam 1, a buzzer 5, a controller 6, a storage battery 11, an infrared sensor 12 and a seed standpipe 21, the buzzer 5 is fixed in the middle of the main beam 1 by bolts, the buzzer The model of the buzzer 5 is: HYT-2312, which sends out an alarm sound through the buzzer 5 to remind the user to check the cause of the leakage of seeds in time and correct it. Switch, the control switch is connected to the storage battery 11 through the cable, the control switch is connected to the controller 6 and the infrared sensor 12 respectively through the cable, and the seeds are passed through the inside of the seed vertical pipe 21, so that the infrared sensor 12 can check whether there are seeds falling in the seed vertical pipe 21 Detect, when sowing is not smooth, find out in time, controller 6 connects infrared sensor 12 by cable, controller 6 is fixed on the main beam 1 by support, and controller 6 rear is p...

Embodiment 3

[0032] see figure 1 , 2 , 3, a kind of vegetable seed sowing machine, comprising main beam 1, seed bucket 14, wheel drum 15, wheel spoke 16, wheel 17 and seed standpipe 21, main beam 1 left end center is provided with wheel axle 19, and wheel axle 19 passes through The bearing is set on the main beam 1, and the wheel drum 15 is arranged in the middle of the wheel shaft 19. The materials used for the wheel drum 15, the wheel spokes 16 and the wheel 17 are all: cast iron, and the wheel drum 15, the wheel spokes 16 and the wheel 17 are made of cast iron to ensure Wheel 17 will not stick too much soil in the process of rotation, so that it is convenient for the user to push and walk, and the practicability of the machine is increased. A wheel spoke 16, the wheel spoke 16 is all fixed on the wheel drum 15 by welding, the wheel spoke 16 other end is provided with a wheel 17, the wheel 17 is fixed on the wheel spoke 16 by welding, and the front of the wheel drum 15 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com