Spinning machine thread feeding device and operation method

一种上线器、纺织机的技术,应用在运送细丝状材料、薄料处理、运输和包装等方向,能够解决放线装置结构复杂化、更换麻烦、影响产品放置工作效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

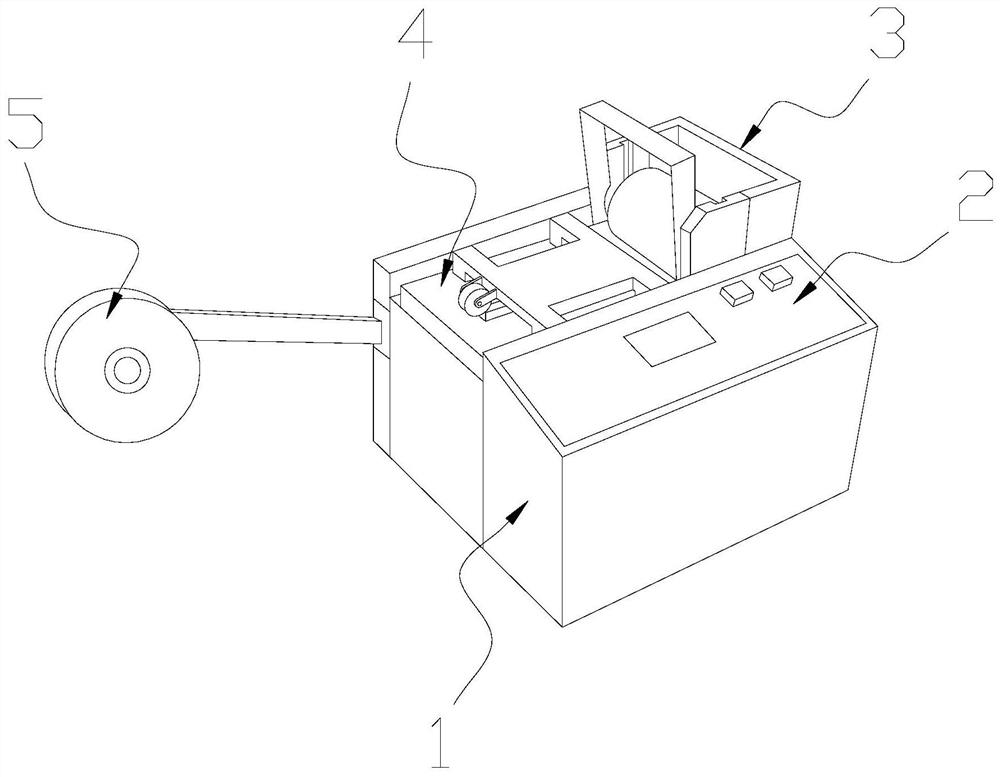

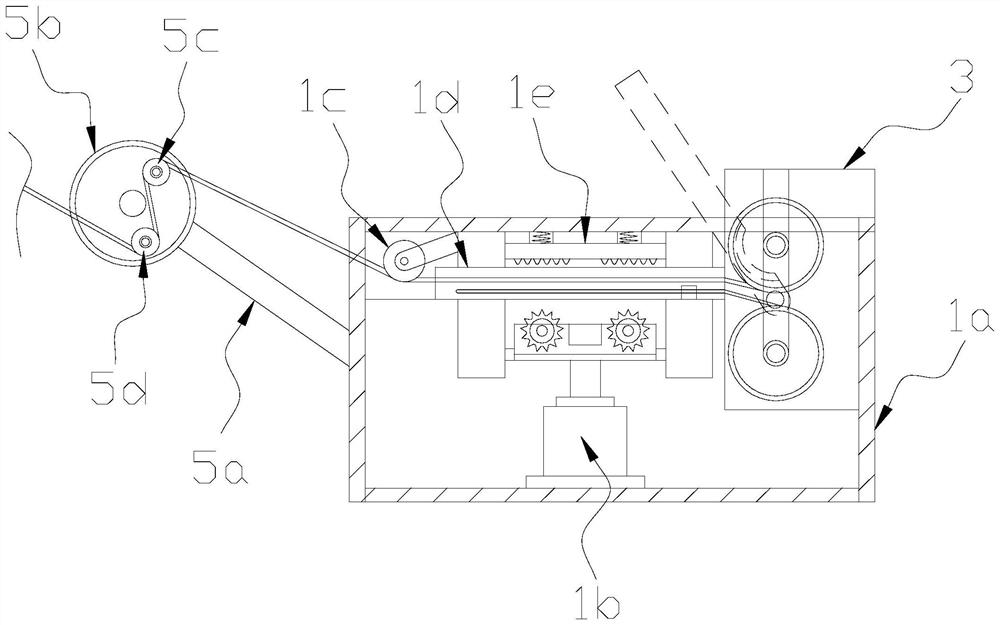

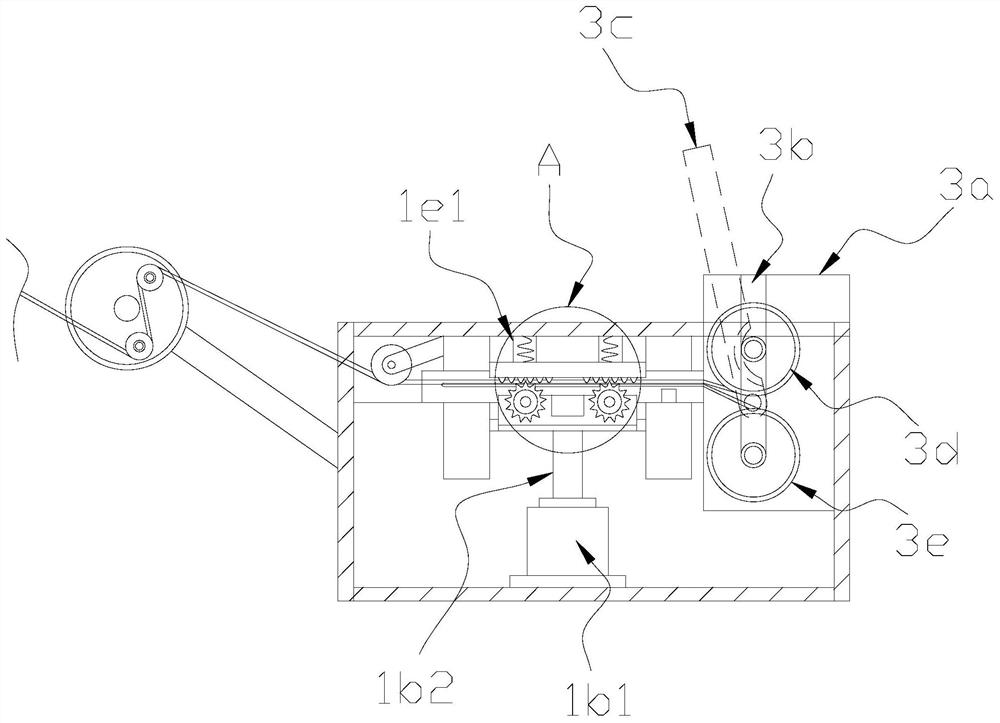

[0029] see Figure 1-Figure 6 , the present invention provides a textile machine threader and its operation method, the structure of which includes a thread payoff 1, an operation panel 2, a wire barrel mechanism 3, a wire slot plate 4, and a wire beam guide wheel frame 5. The thread payoff 1 An operation panel 2 is installed on the surface, and a bobbin mechanism 3 is provided on the top of the pay-off device 1. The pay-off device 1 and the bobbin mechanism 3 cooperate, and a bundle The wire guide wheel frame 5, the described wire payoff 1 and the harness guide wheel frame 5 adopt clearance fit, and the wire slot plate 4 is arranged on the top of the described wire payoff 1, and the wire slot plate 4 described in the wire payoff 1 connected, the wire pay-off device 1 is composed of a housing 1a, a wire replenishing mechanism 1b, a wire pressing guide wheel 1c, a wire rail 1d, a wire pressing mechanism 1e, and an infrared sensor 1f. The inner bottom of the housing 1a is There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com