Internal corner connecting structure and mounting method

A technology for connecting structures and inside corners, applied in building construction, covering/lining, architecture, etc., can solve problems such as unsatisfactory aesthetic and visual effects, difficult splicing and fixing of inside corners, and protruding too much.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

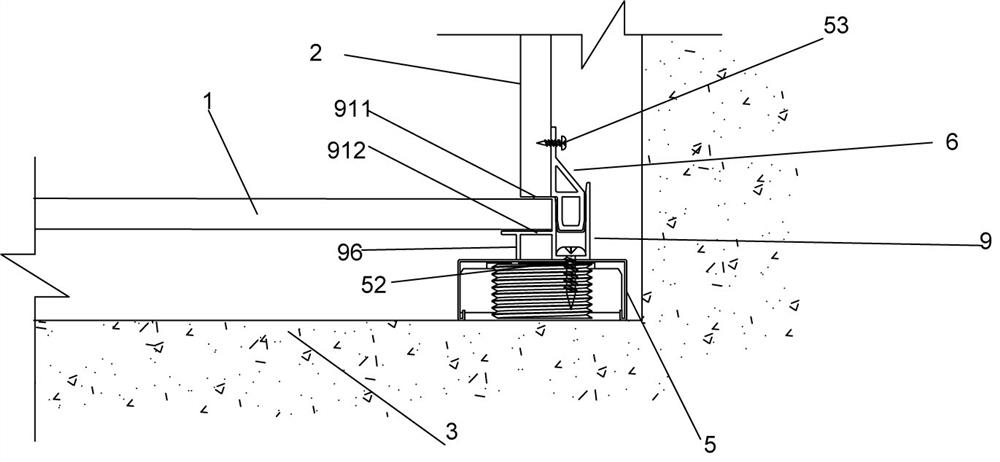

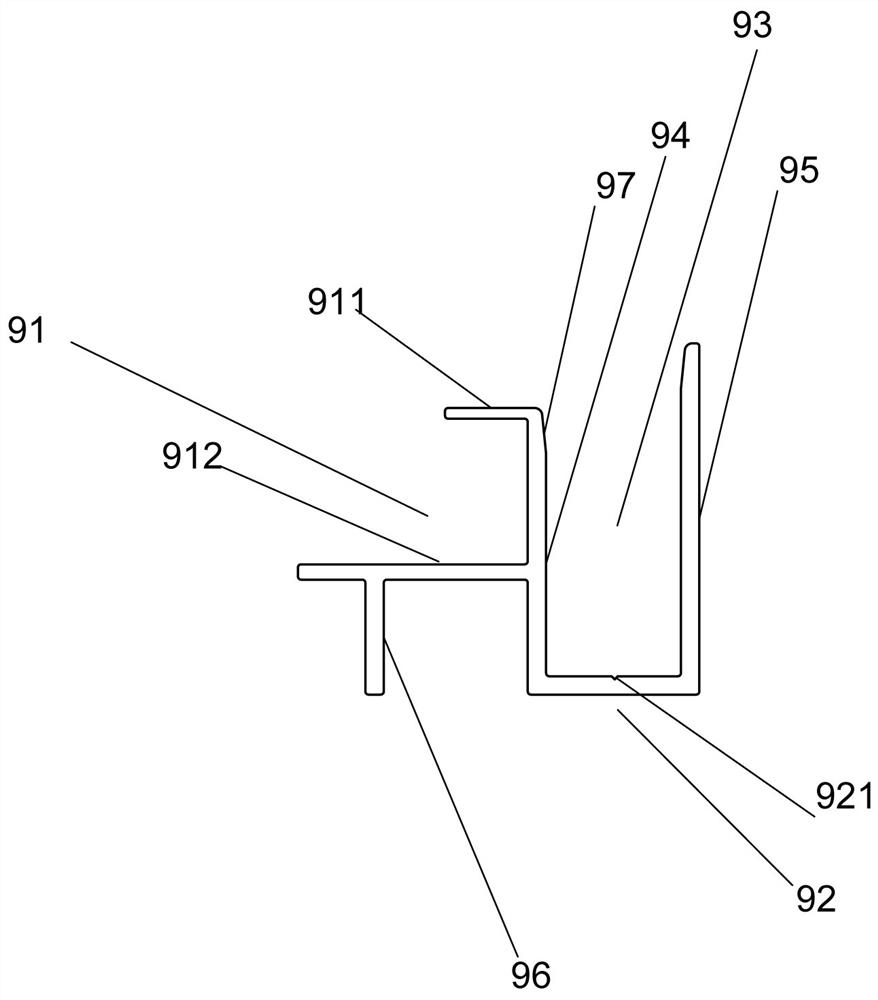

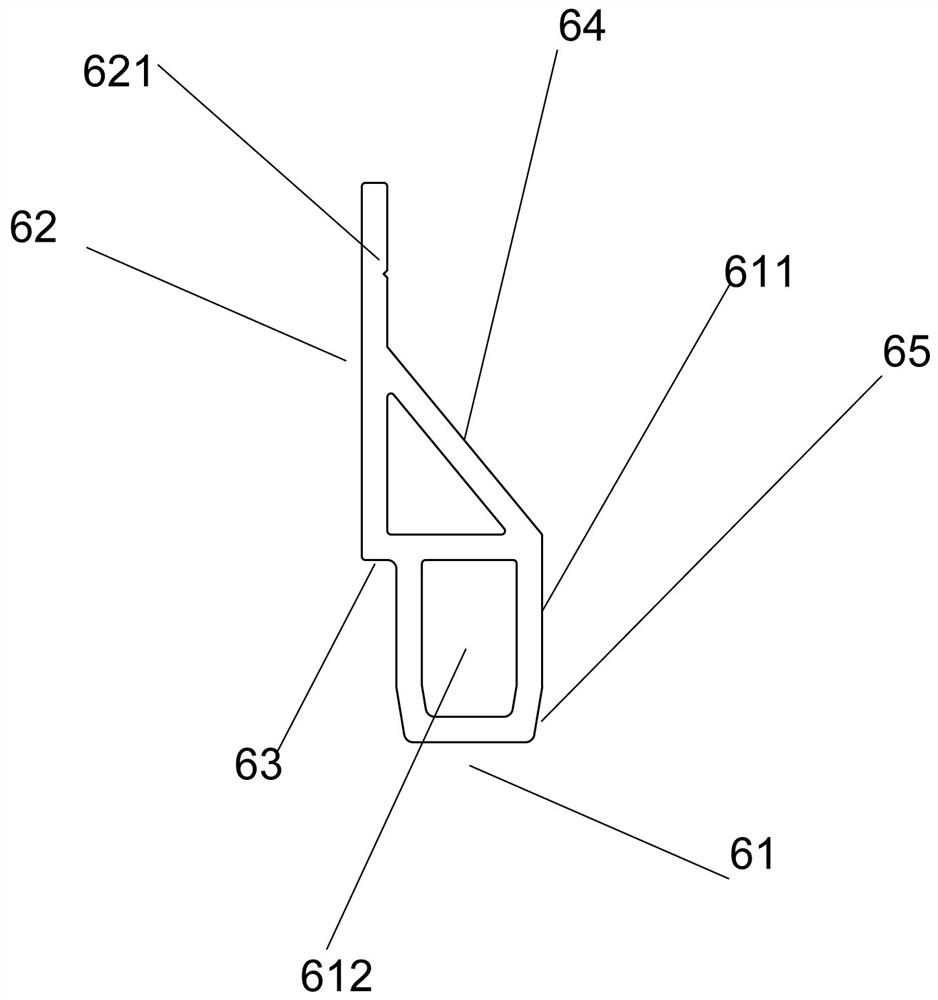

[0031] like figure 1 As shown, an internal corner connection structure is used for splicing and fixing two wall panels at the internal corner of the wall. The internal corner connection structure includes: an edge fixing part 9, which has a first installation buckle groove 93, and a The first edge-limiting groove 91 for fixing the edge of the end of the first wallboard 1, and the third fitting surface 92 attached to the wall 3 and fixedly connected with the wall 3; the buckle connector 6 has Insert the first buckle part 61 of the first installation buckle groove 93, and the fourth fitting surface 62 attached to the second wallboard 2 and fixedly connected with the second wallboard 2; After the buckle connector 6 is inserted and fixed, the first wallboard 1 and the second wallboard 2 fixed on the edge fixing member 9 and the buckle connector 6 can be spliced together.

[0032] A leveling member 5 is arranged between the edge fixing member 9 and the wall 3 . The leveling mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com