Shared tool management system

A tool management and tool technology, applied in the field of shared tool management system, can solve problems such as the inability to count tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

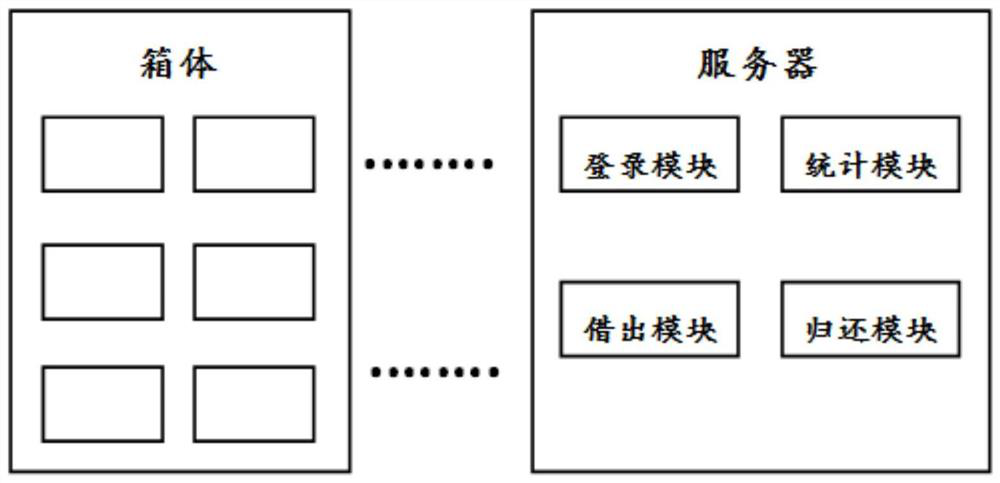

[0034] An embodiment of a shared tool management system of the present invention is basically as attached figure 1 As shown, including: cabinet and server;

[0035] The cabinet has several grids, each grid is equipped with a cabinet door, and the cabinet door is equipped with an induction control door lock; each grid is equipped with an RFID reader, and the RFID reader is installed inside the grid. RFID electronic tags; RFID electronic tags are used to send signals in real time, and RFID readers are used to receive signals in real time and send the identification results to the server;

[0036] The server includes a login module, a statistics module, a lending module and a return module;

[0037] Login module, used for users to log in personal information;

[0038] Statistics module, used for real-time statistics of the number of tools in each cabinet of the cabinet;

[0039] The lending module is used for the user to fill in the name of the tool that the user wants to lend...

Embodiment 2

[0047] The only difference from Embodiment 1 is that the grid includes three specifications of large, medium and small, and in terms of volume, large > medium > small. Through this design, the largest tool is placed in the large grid, the next largest tool is placed in the medium grid, and the smallest tool is placed in the small grid, which is conducive to making full use of the space of the box . In addition, the grids are arranged side by side, and rollers are installed on the bottom of the box, so that the whole box can be moved easily.

Embodiment 3

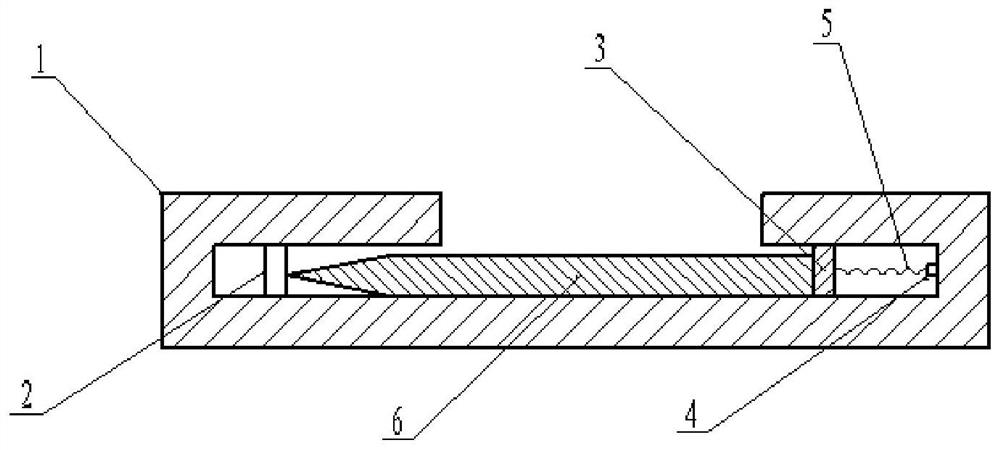

[0049] The only difference with embodiment 2 is that for some special knives 6, for example, the machete of pig bones, this kind of knives are not commonly used in life, so they need to be shared sometimes. When the tool demander returns the special tool 6 , it is necessary to determine whether there is a gap in the special tool 6 .

[0050] Specifically, the box body is provided with a grid for placing special knives 6, as attached figure 2 As shown, it includes: a housing 1, the cross section of the housing 1 is rectangular, and the upper surface of the housing 1 is provided with through holes; a plurality of steel columns 2, the steel columns 2 are located inside the housing 1, and the steel columns 2 are located in the housing 1 on the left side, the upper end of the steel column 2 is welded to the upper surface inside the shell 1, the lower end of the steel column 2 is welded to the lower surface inside the shell 1, and the steel columns 2 are arranged in a straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com