AGC cylinder performance parameter monitoring method introducing adaptive optimization algorithm

An optimization algorithm and parameter monitoring technology, which is applied in the direction of calculation, measurement devices, data processing applications, etc., can solve the problem of high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

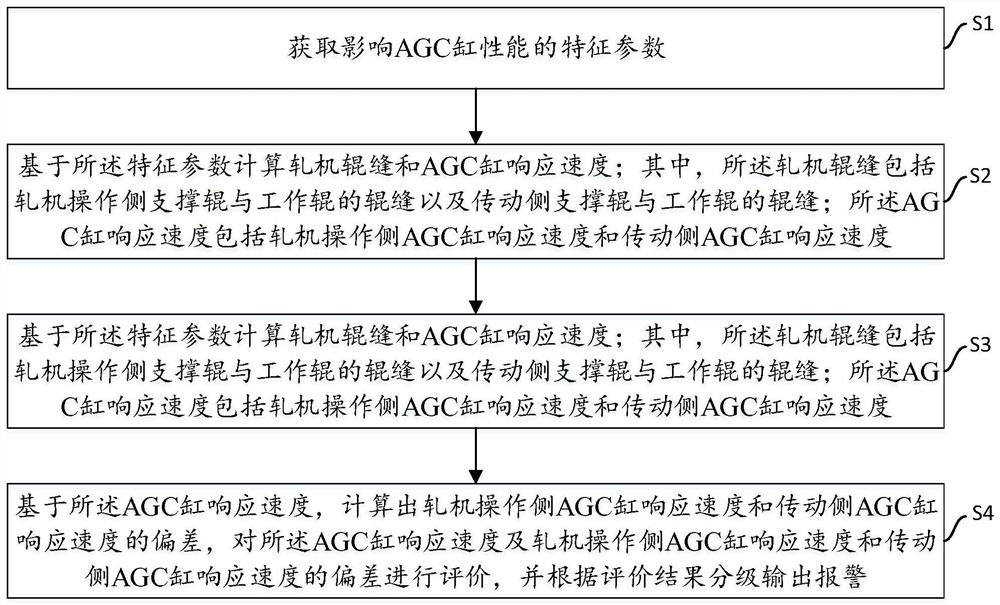

[0052] This embodiment provides a method for monitoring performance parameters of an AGC cylinder that introduces an adaptive optimization algorithm, such as figure 1 As shown, the AGC cylinder performance parameter monitoring method that introduces an adaptive optimization algorithm includes:

[0053] S1, obtaining the characteristic parameters affecting the performance of the AGC cylinder;

[0054] It should be noted that the failure of the AGC cylinder in the project is mainly caused by problems such as internal leakage, jamming and servo valve, and the main reason reflected in the performance parameters is the change of the response speed of the piston or cylinder.

[0055] Specifically, in this example, the input parameters are: operating side AGC cylinder position setting value, operating side AGC cylinder position actual value, driving side AGC cylinder position setting value, driving side AGC cylinder position actual value, operating side inlet magnetic ruler position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com