Anti-seismic cable bridge

A cable tray, anti-vibration technology, applied in electrical components, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problems of cable tray shaking, loose connection and easy falling off, heavy cable weight, etc., to achieve good seismic resistance, reduce Impact, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

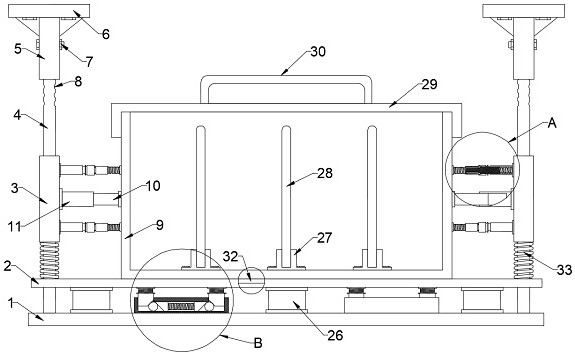

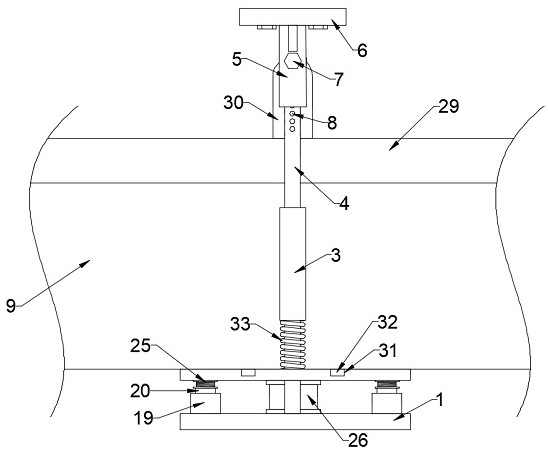

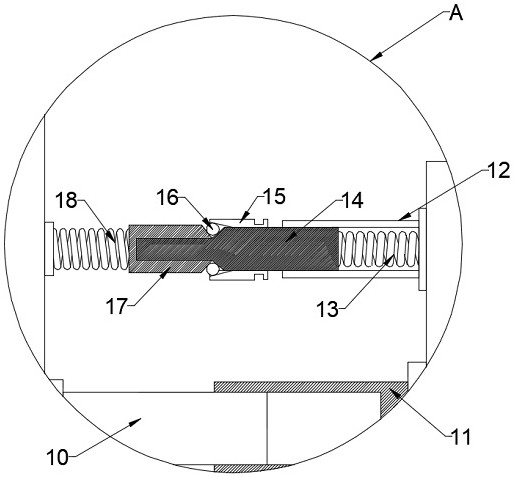

[0025] see Figure 1~5 , in an embodiment of the present invention, an anti-seismic cable tray includes a cable placement frame 9, a bottom fixing plate 1 and two upper fixing seats 6, the bottom fixing plate 1 is provided with a buffer adjustment plate 2, the A bottom anti-seismic mechanism is arranged between the buffer adjustment plate 2 and the bottom end fixed plate 1, and the cable placement frame 9 is slidably installed on the upper end surface of the buffer adjustment plate 2, and the two upper end fixing seats 6 and the bottom end fixed plate 1 are provided with a fixed shaft body 4, and a multi-stage anti-seismic mechanism is arranged between the fixed shaft body 4 and the side wall of the cable placement frame 9, and the multi-stage anti-seismic mechanism includes two rod sleeves 3, and two The rod sleeves 3 are respectively slidably mounted on the outer sidewalls of the two fixed shaft bodies 4, and the two rod sleeves 3 are provided with two shock absorbing sleeve...

Embodiment 2

[0032] see figure 1 The difference between the embodiment of the present invention and embodiment 1 is that the two upper fixing seats 6 are provided with adjusting sleeves 5 fixedly connected thereto, and the two fixed shafts 4 are provided with multiple An adjustment through hole 8, one end of the fixed shaft body 4 is set in the inner cavity of the adjustment sleeve 5 and the side wall of the fixed shaft body 4 is slidingly connected with the inner side wall of the adjustment sleeve 5, and the adjustment sleeve 5 is provided with There is an adjusting bolt 7 for fixing the end of the fixed shaft 4. When installing the entire bridge, the end of the fixed shaft 4 can first slide on the inner wall of the adjusting sleeve 5 to adjust the height of the entire bridge. , and then the fixed shaft body 4 is fixed on the adjusting sleeve 5 through the cooperation of the adjusting bolt 7 and the adjusting through hole 8 .

[0033] The working principle of the invention is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com