Dust-free concrete aggregate batching device

A technology for concrete aggregates and aggregates, which is used in clay preparation devices, raw material supply devices for sales, mixing operation control devices, etc. The effect of improving work accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

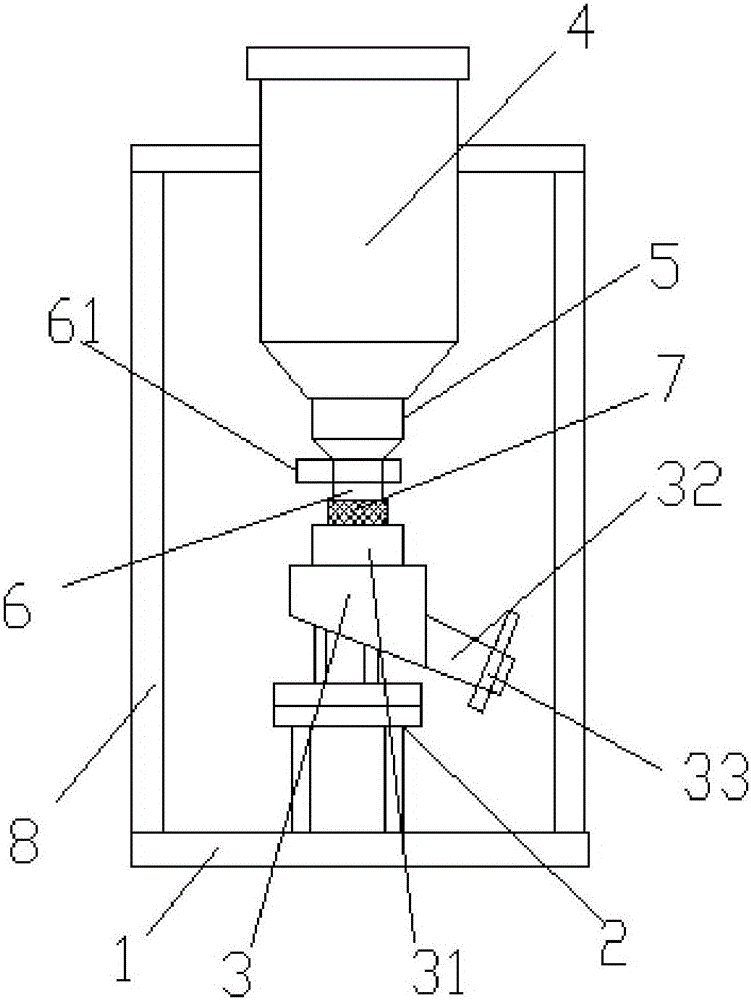

[0013] Combine below figure 1 And further illustrate the technical solution of the present invention through specific examples.

[0014] A concrete aggregate dust-free batching device, comprising: a fixed base 1 and an aggregate storage tank 4, the aggregate storage tank 4 is arranged above the fixed base 1, and the fixed base 1 is provided with an aggregate storage tank 4 below the weighing device 2, a material receiving box 3 is arranged above the weighing device 2, and the top of the material receiving box 3 is provided with a material receiving pipe 31 pointing to the aggregate storage tank 4. The bottom of the material storage tank 4 is provided with a feed pipe 6 extending into the feed pipe 31, and a dust-proof collar 7 is arranged between the outer circle of the feed pipe 6 and the inner wall of the feed pipe 31, and the feed pipe 31 is concentric with the feeding pipe 6, the aggregate enters the receiving box 3 below through the feeding pipe 6 and the feeding pipe 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com