Process for limiting drug amount directional blasting replacement mollisol stone packing

A directional blasting, soft soil technology, applied in the field of embankment and dam, can solve the problems of low work efficiency, long construction period and high cost, and achieve the effect of simple charging tools, solving hazards and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

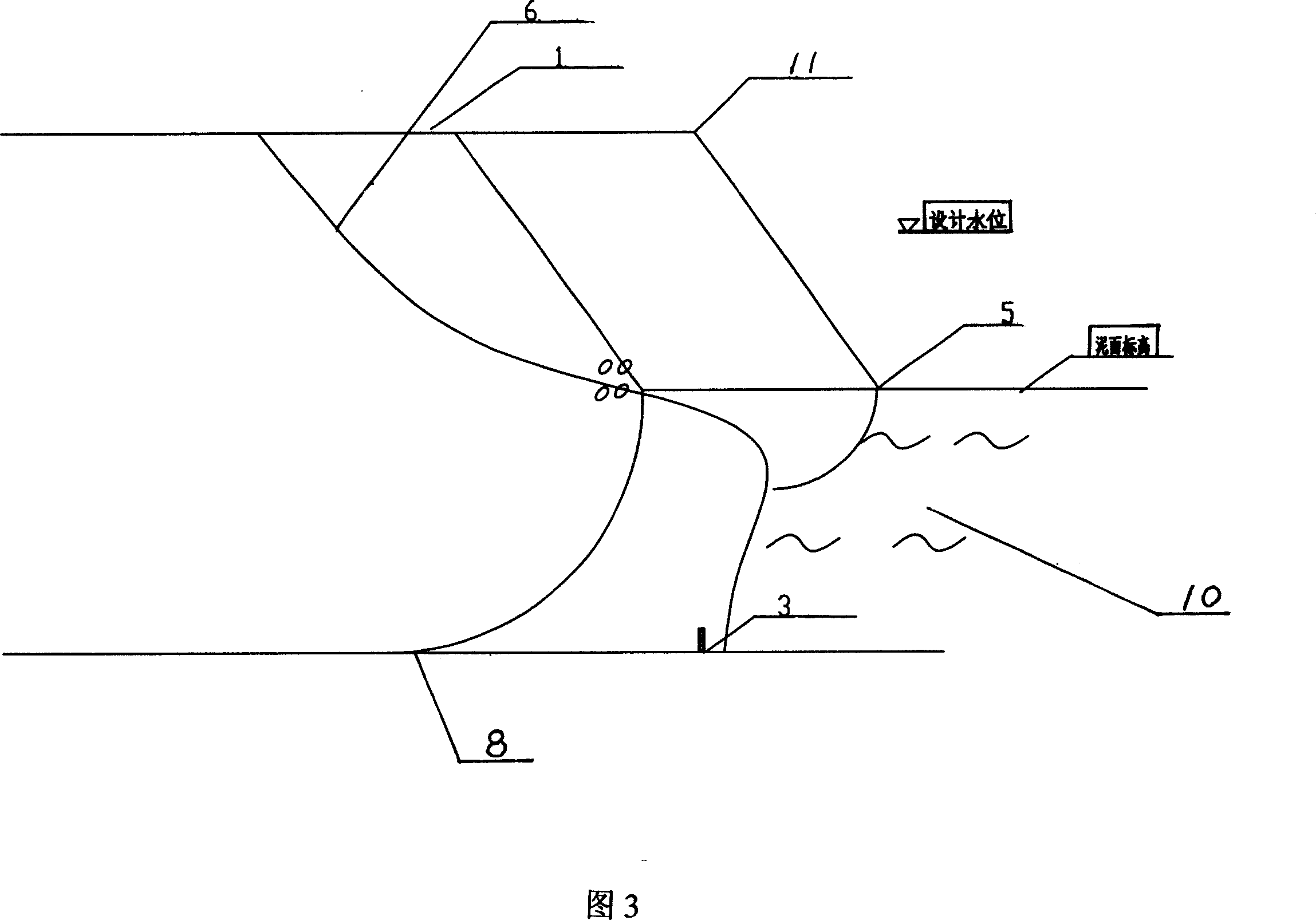

[0028] Taking the Fishing Port Breakwater Project in Taizhou, Zhejiang Province as an Example

[0029] The breakwater project of the fishing port in Taizhou, Zhejiang Province has a dike length of 530m, a stone body elevation of +5.5m, a width of 10m, an elevation of underwater mud surface of -3m~-5m, and a thickness of silty soft soil of 10~15m. There are 3 oil storage tanks at 50m away from the root of the embankment and a gravity wharf at 90m away, and the blasting method must be used to protect their normal use and safety.

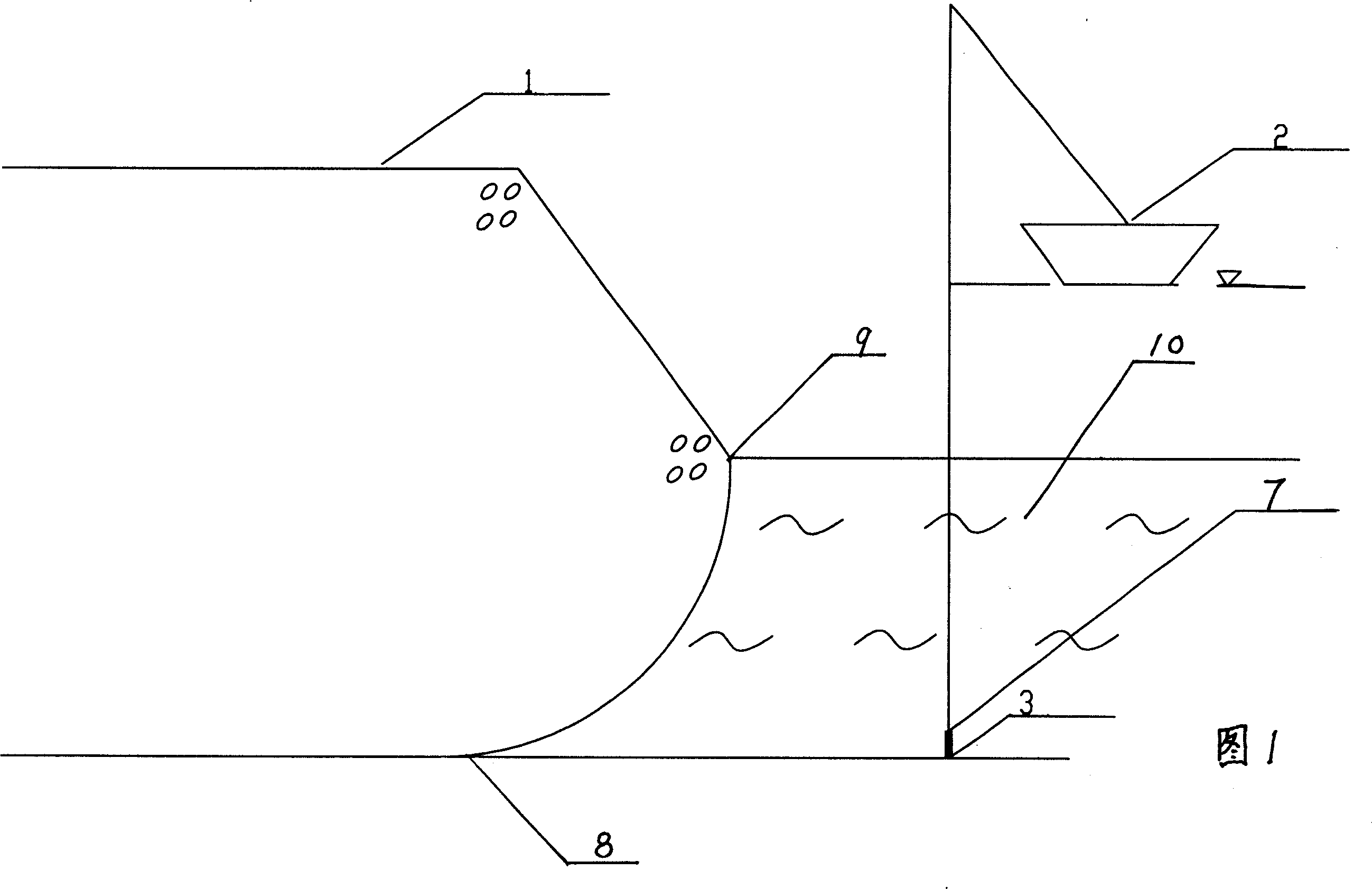

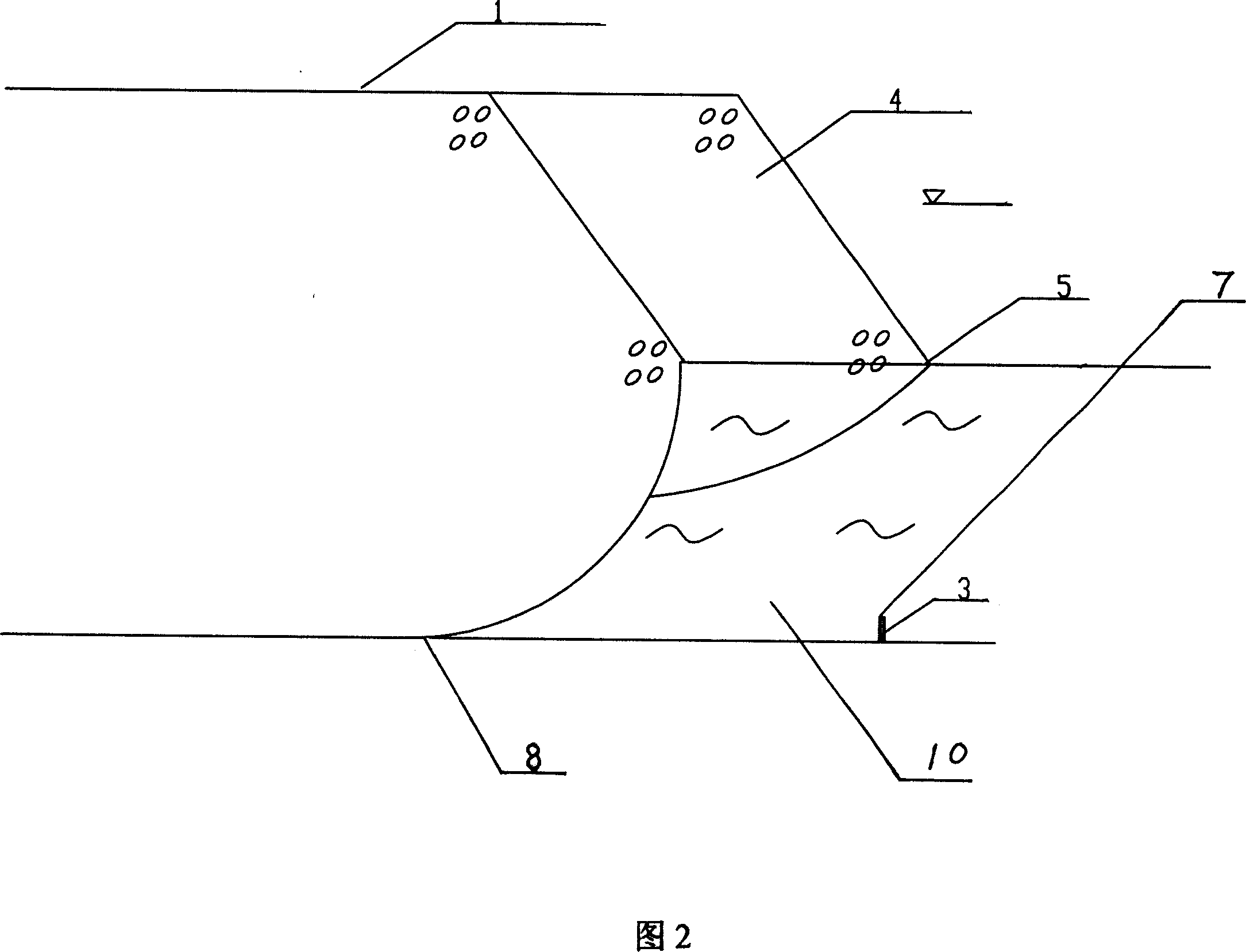

[0030] A method for replacing soft soil rockfill by directional blasting with a limited amount of charge, as shown in Figure 1, is a schematic diagram of the initial throwing and distributing of the preliminary fill body, using the method of deep burying the explosives, and distributing the explosives, the steps are:

[0031] Step 1: Preliminary throwing of the filling body, using the pre-embedded method to distribute the medicine

[0032] a. Do not c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com