A high-reflectivity powder surface spraying device for lighting processing

A high-reflectivity, surface spraying technology, applied in the direction of the spraying device, can solve the problems of inconvenient loading and unloading, uneven powder spraying, etc., and achieve the effect of uniform powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

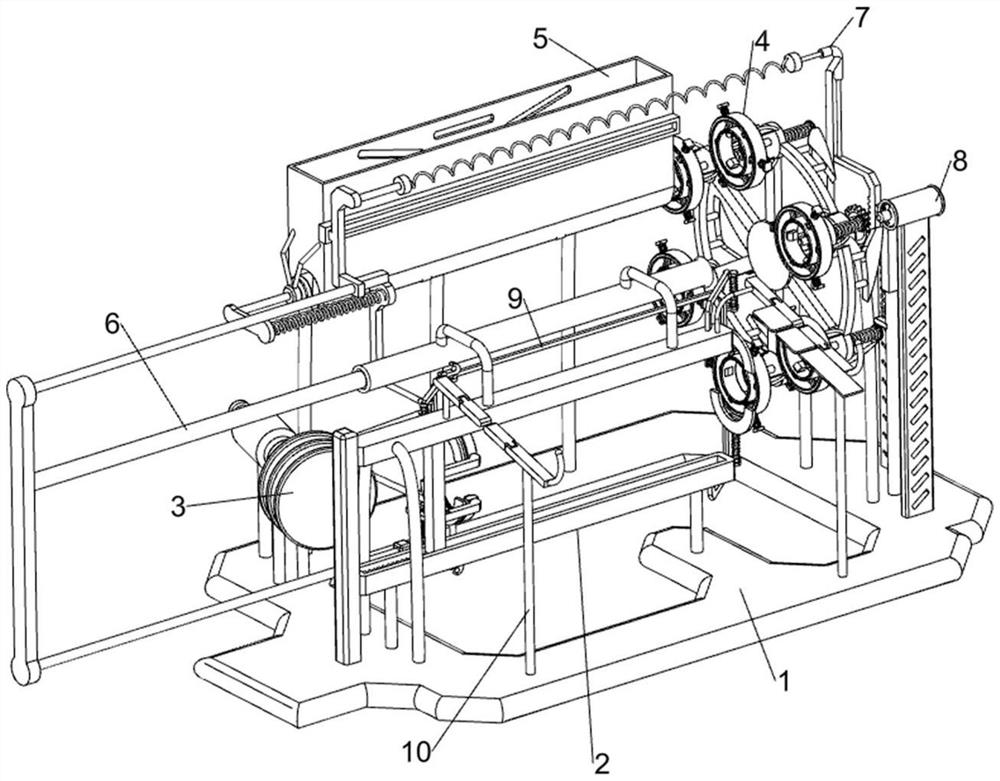

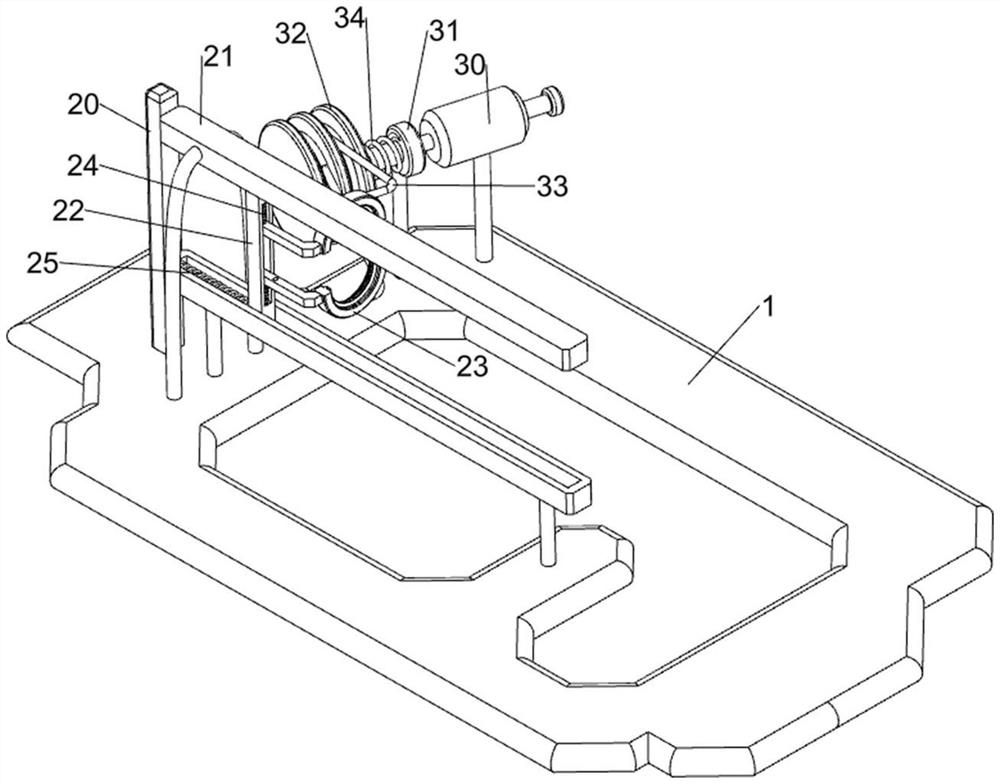

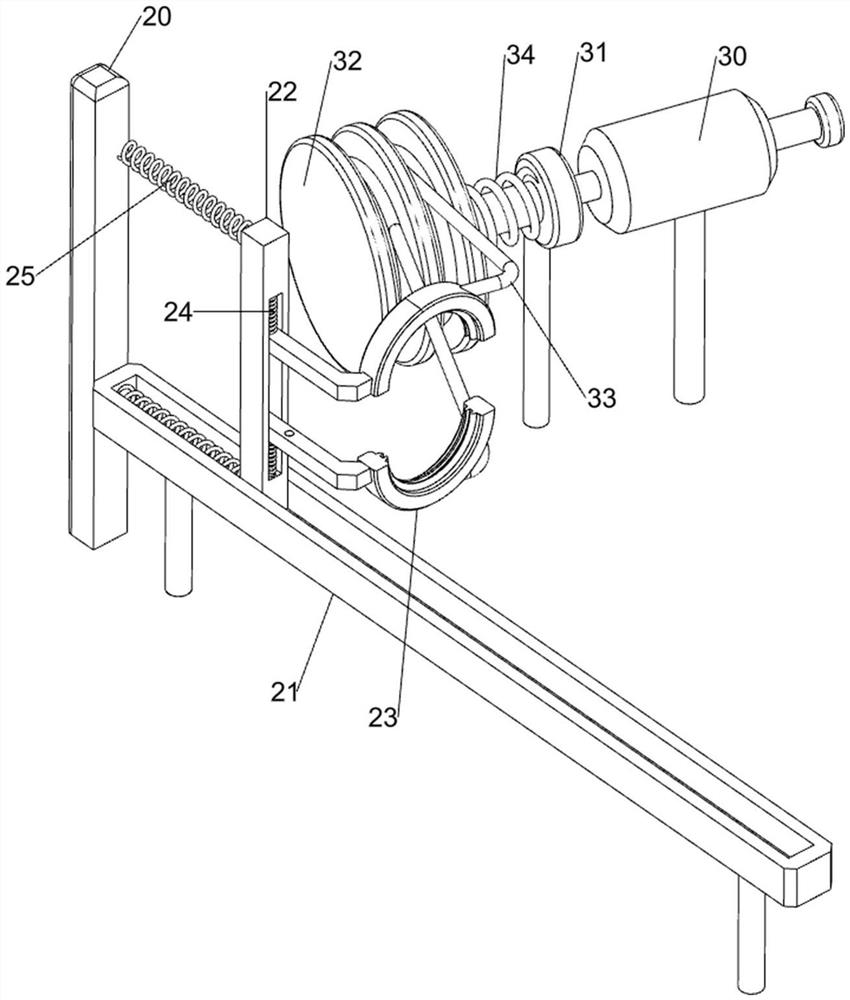

[0034] A high-reflectivity powder surface spraying device for lighting processing, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a base 1, a spraying mechanism 2, a feeding mechanism 3 and a feeding mechanism 4. The left side of the base 1 is provided with a spraying mechanism 2, the upper left side of the base 1 is provided with a feeding mechanism 3, and the upper left side of the base 1 is provided with a feeding mechanism 3. The side is provided with feeding mechanism 4.

[0035] The spraying mechanism 2 includes a mounting column 20, a slide rail 21, a chute plate 22, an annular nozzle 23, a first tension spring 24 and a return spring 25, the left side of the base 1 is fixedly connected with the mounting column 20, and the right side of the mounting column 20 The upper part and the upper front side of the base 1 are connected with slide rails 21, slide rails 21 are provided with a chute plate 22, and the chute plate 22 is symm...

Embodiment 2

[0040] On the basis of Example 1, such as Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a feeding assembly 5 is also included, and the feeding assembly 5 includes a fixed rod 50, a feeding frame 51, an elastic sheet 52, a sliding seat 53, a push plate 54 and a connecting plate 55, and the rear side of the base 1 is evenly spaced and fixed. Three fixed rods 50 are connected, and a feeding frame 51 is connected between the tops of the fixing rods 50. The bottom of the feeding frame 51 is symmetrically connected with an elastic piece 52, and the left side of the feeding frame 51 is connected with a sliding seat 53, and the sliding seat 53 is of a sliding type A push plate 54 is provided, and a connecting plate 55 is connected to the left end of the push plate 54 .

[0041] Also includes a power assembly 6, the power assembly 6 includes a guide rail 60, a sliding rod 61, a sliding sleeve 62, a sliding rail 63, a rack 64, a one-way gear 65, a first spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com