Improved piston detection machine

A testing machine and an improved technology, applied in the field of testing machines, can solve the problems of delay in feeding and poor continuity, and achieve the effects of rapid replacement, shortening cycle period and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

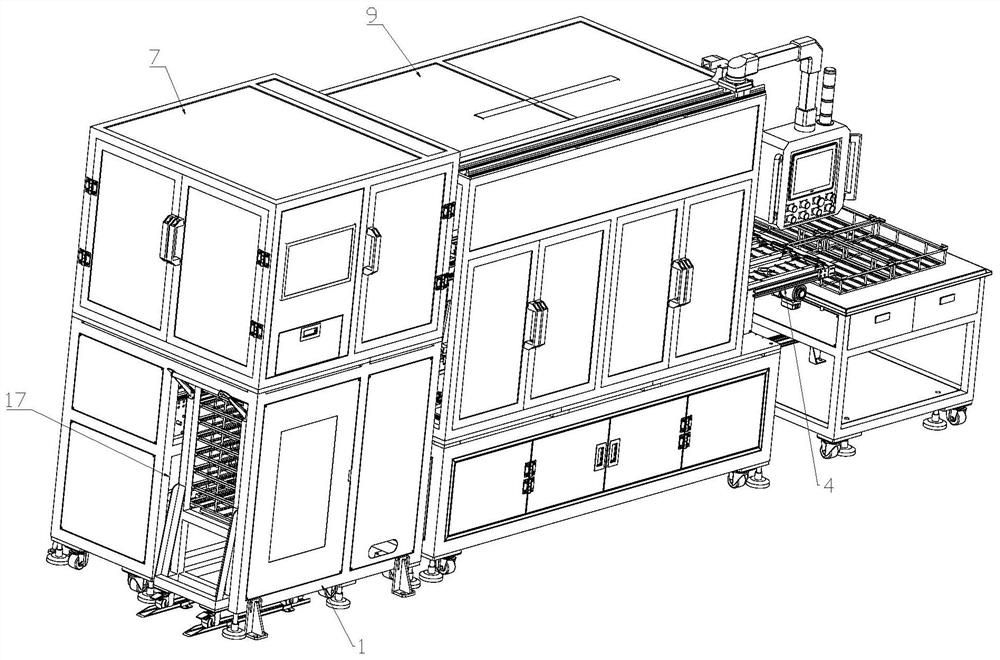

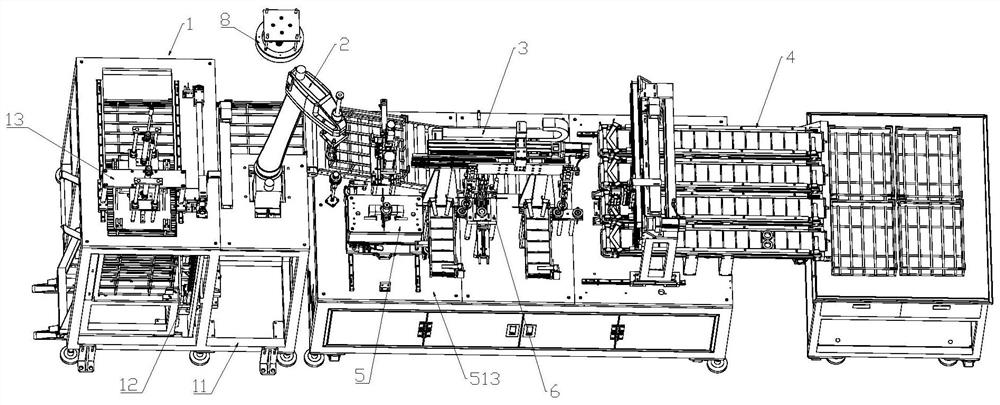

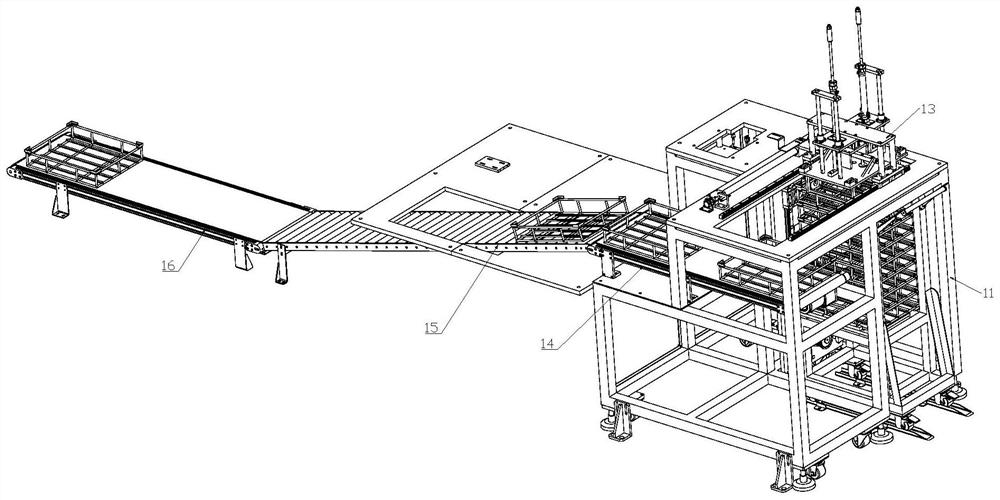

[0039]CombineFigure 1 to 16An improved piston detector, in the present embodiment, including upper level 1, detection position, upper robot 2, handling mechanism 3 and a registered position 4, and the upper robot 2 is located in the upper position 1 and Between the detection position, it is used to feed the product at the upper position 1 to the detection bit, and the detection bit is used to detect whether the product is qualified. If so, the product is sent to the receiving position 4, the receiving position 4 For collecting qualified products; the upper level 1 includes a lift rack 11, a lifting portion 12, a casing jam portion 13, a sheet conveyor belt 14, a non-warrant conveying line 15, and a frame conveyor belt 16; lifting unit 12 The upper channel bits 17 fixed to the lift rack 11 is supplied to the housing frame of the pallet sheet to the material frame claw portion 13; the casing jaw portion 13 slides on the lifting rack 11, which is capable of clamping The material is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com