A Rear Axle Adjustment Mechanism of Electric Forklift Cartridge

A tooling trolley and electric forklift technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of unadjustable distance and poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

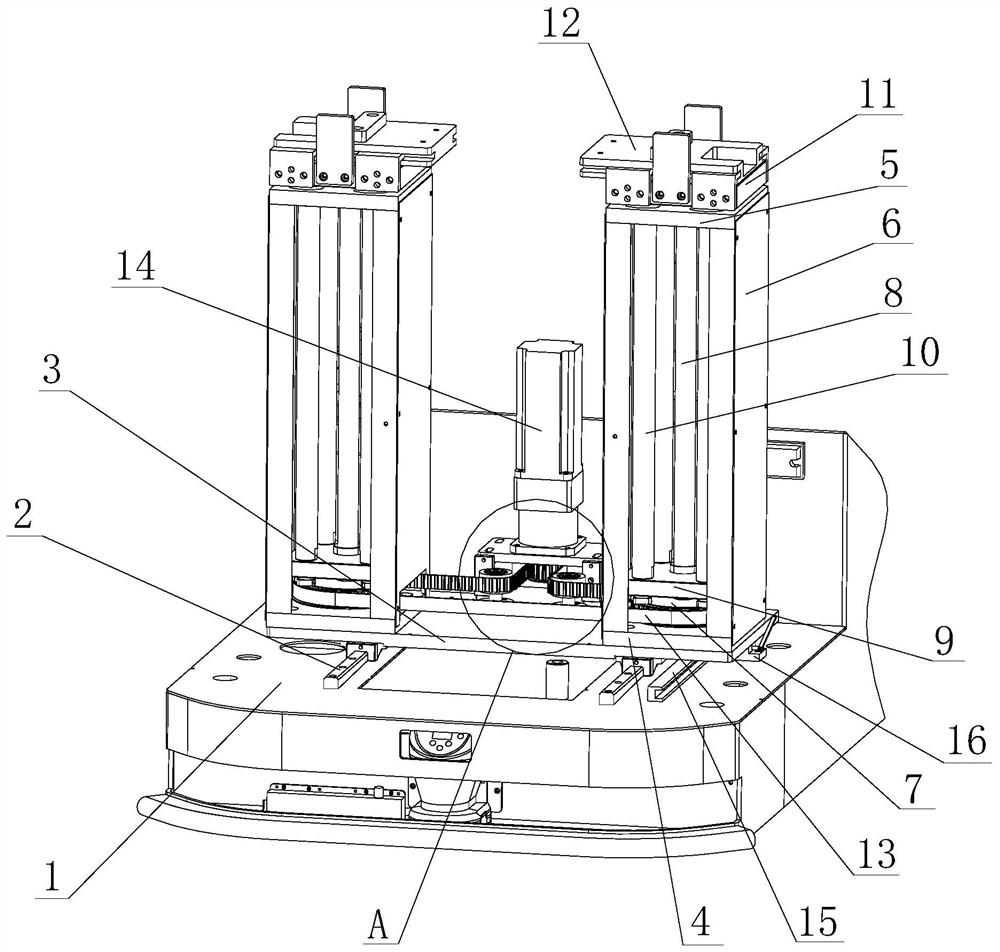

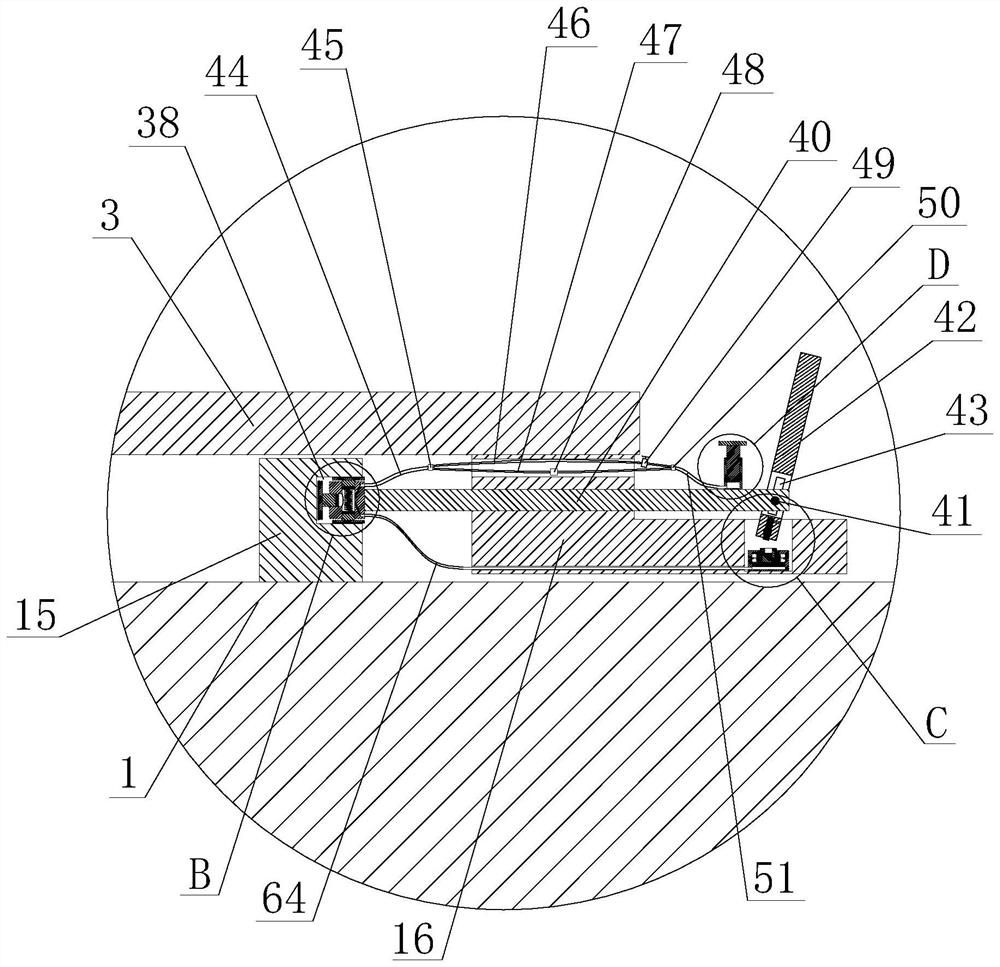

[0026] Such as Figure 1 to Figure 7 As shown, a rear axle adjustment mechanism of an electric forklift trolley includes a base 1 on which a guide rail 2 is arranged. A sliding adjustment seat 3 is slidably connected to the guide rail 2 . A sliding locking device is arranged between the sliding adjustment seat 3 and the base 1 , a lifting drive device is arranged on the sliding adjustment seat 3 , and a rear axle supporting positioning plate 12 is arranged on the lifting driving device. The rear axle support positioning plate 12 is used for supporting and positioning the rear axle 83 .

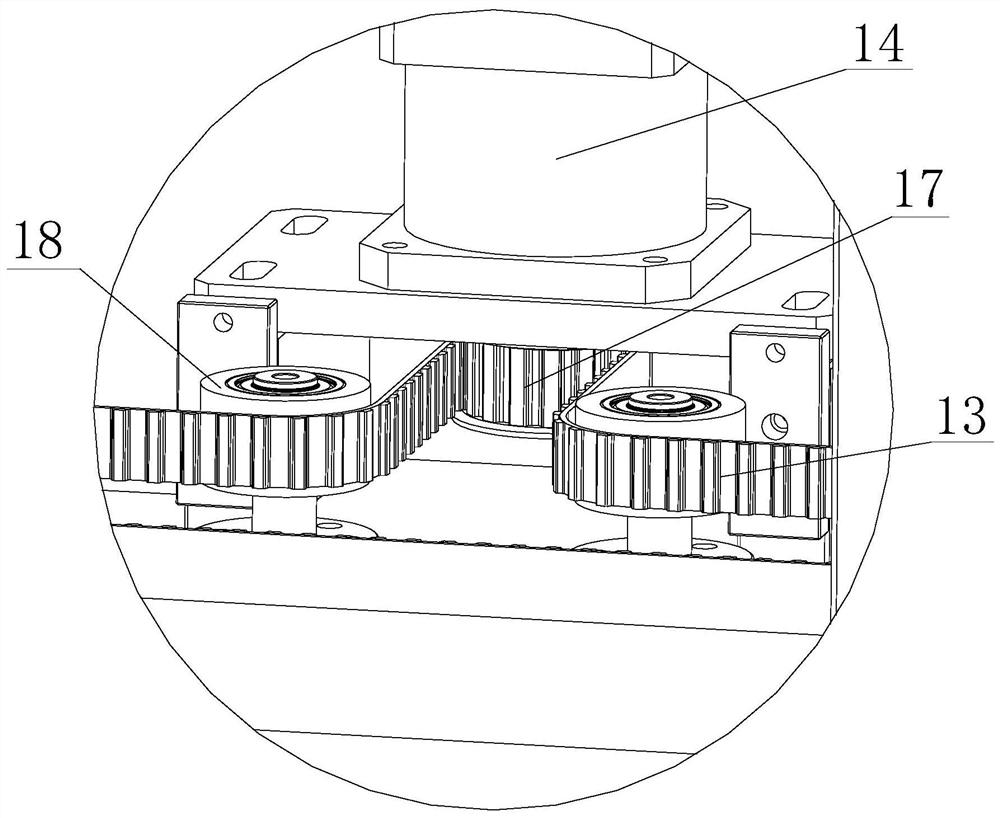

[0027] Lifting driving device comprises column, motor 14, belt 13. There are two columns, which are located on both sides of the sliding adjustment seat 3 respectively. The column includes a lower end plate 4 and an upper end plate 5 , and a side plate 6 is connected between the lower end plate 4 and the upper end plate 5 . A screw mandrel 8 is rotatably connected to the column, and the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com