High-pressure point cooling water collecting block for mold

A technology of high pressure and mould, which is applied in the field of cold water collection blocks at high pressure points, can solve the problems of inconvenient installation process and high processing difficulty, and achieve the effect of simplifying the installation process, facilitating processing, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

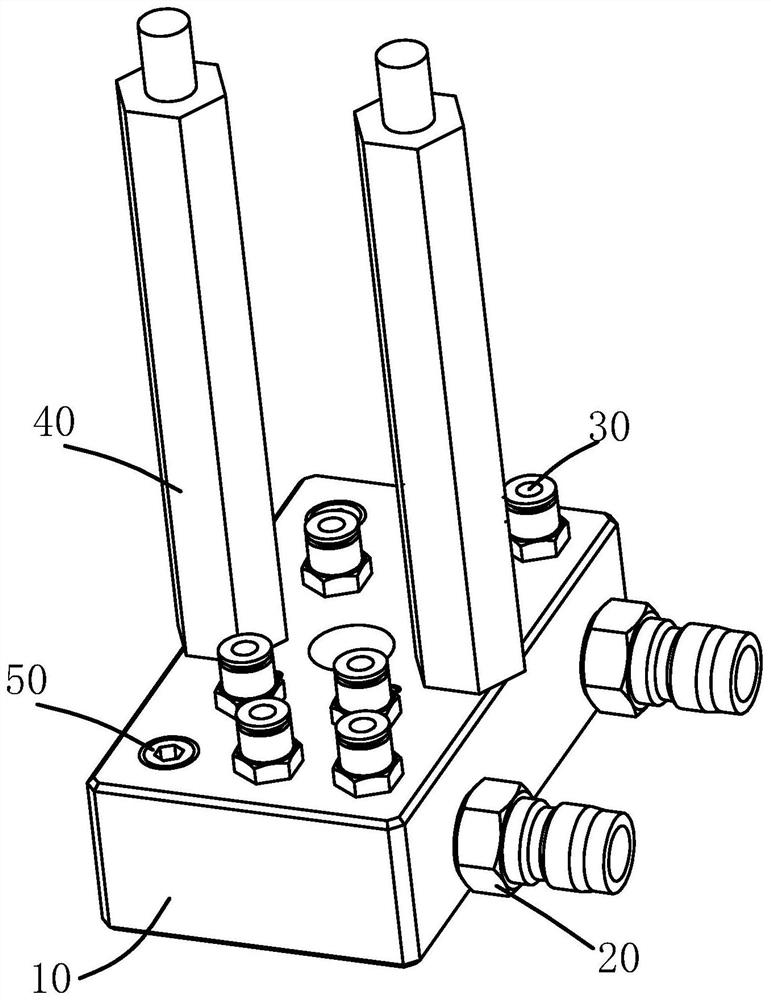

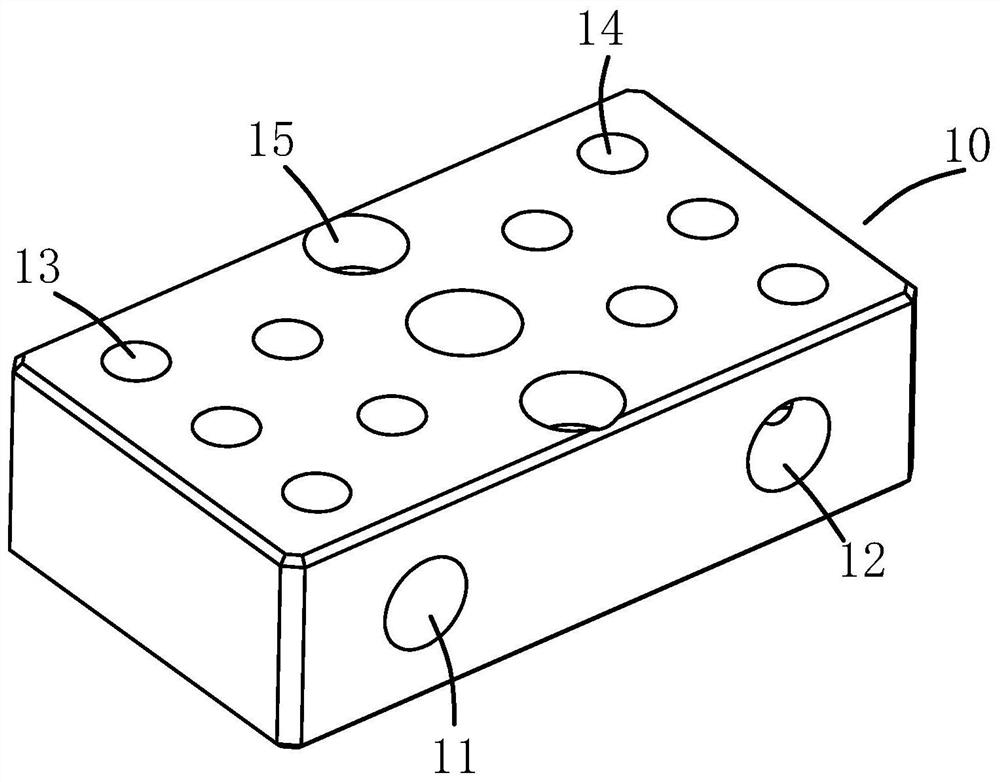

[0018] Such as Figure 1 to Figure 4 As shown, a high-pressure point cooling water collection block for molds according to the present invention includes: a body 10 , a body joint 20 , a water pipe joint 30 , a connecting piece 40 and a plug 50 .

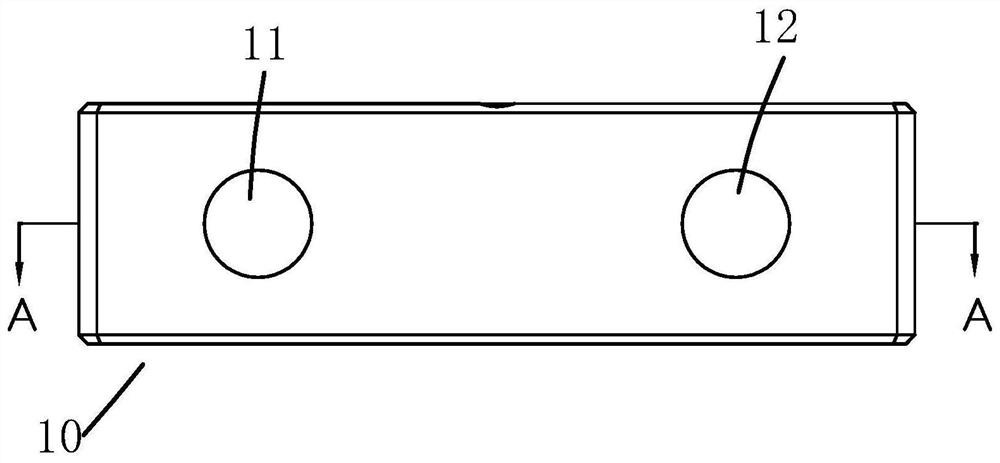

[0019] The side of the body 10 is provided with a water inlet channel 11 and a water return channel 12 , both of which are formed extending from one side of the body 10 to the other side of the body 10 along the width direction of the body 10 . The opening directions of the water inlet channel 11 and the water return channel 12 are determined according to actual requirements, and the opening directions of the water inlet channel 11 and the water return channel 12 can be consiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com