Multi-layer nylon bag folding machine capable of achieving secondary folding and compaction

A nylon bag and folding machine technology, applied in packaging, etc., can solve the problems of low production efficiency, inability to compact multi-layer nylon bags, high labor costs, etc., and achieve the effect of high-efficiency compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

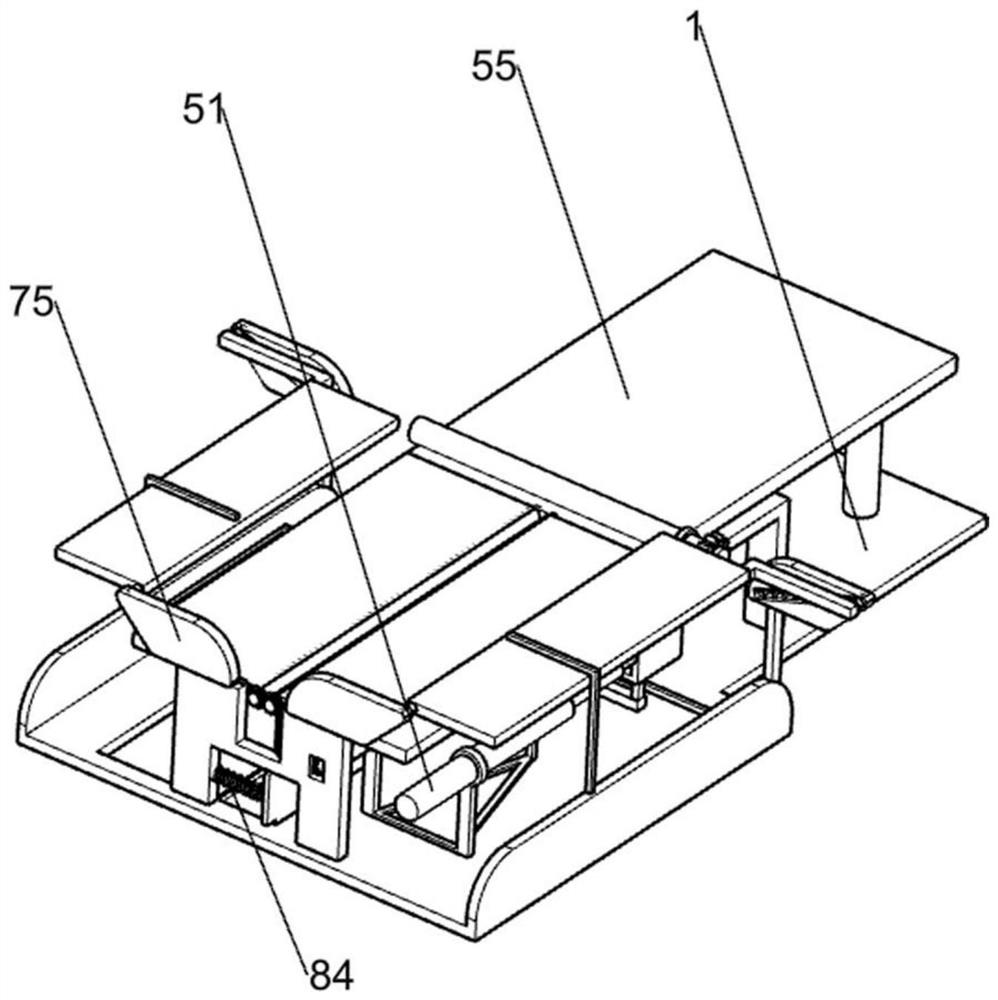

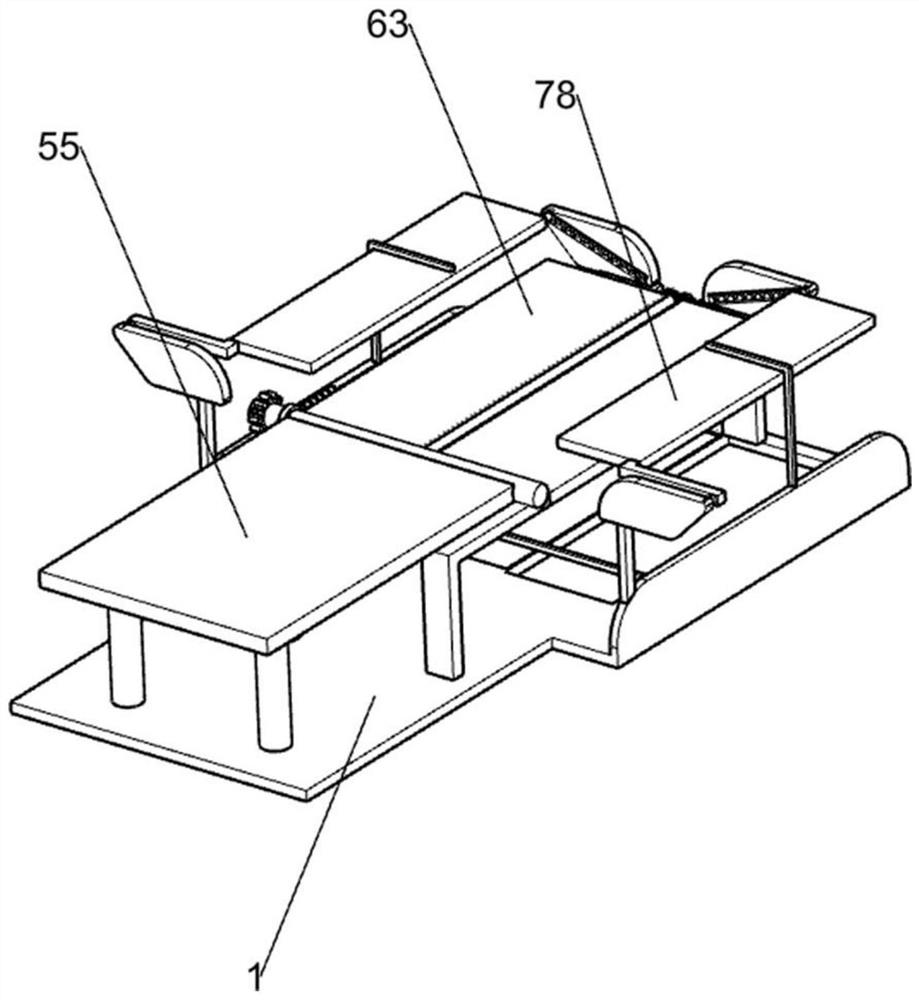

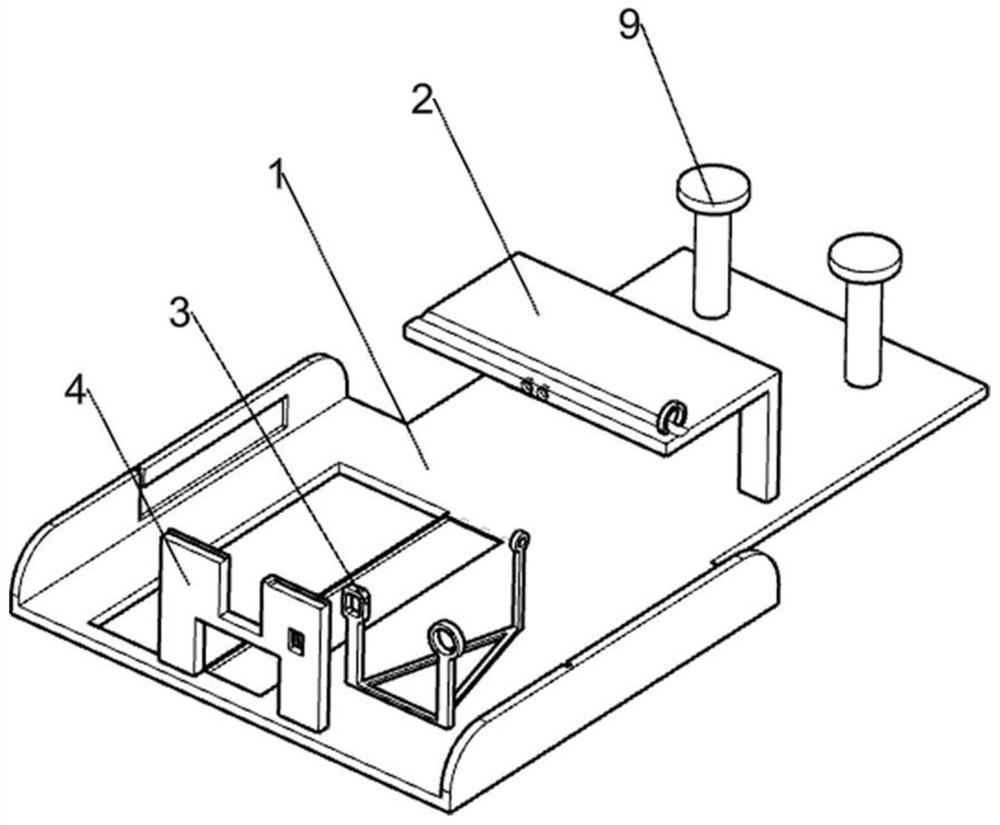

[0027] A double-folding and compacting multi-layer nylon bag folding machine, such as Figure 1-10 As shown, it includes a bottom plate 1, a T-shaped shaft support frame 2, a triangular shaft frame 3, an H-shaped support guide plate 4, a cover mechanism 5, a longitudinal folding mechanism 6, a compacting mechanism 7, and a pushing mechanism 8. The top of the bottom plate 1 is provided with T-shaped rotating shaft support frame 2, the top of the base plate 1 is provided with a triangular rotating shaft frame 3, the H-shaped support guide plate 4 is located on the top of the base plate 1, and the base plate 1 is provided with a flip mechanism 5, which is used to place the multi-layer nylon bag first. For secondary folding, the bottom plate 1 is provided with a longitudinal folding mechanism 6, the folding mechanism 6 is used to fold the compressed multi-layer nylon bag for the second time, and the bottom plate 1 is provided with a compacting mechanism 7, which is used to fold the...

Embodiment 2

[0035] On the basis of Example 1, such as image 3 As shown, there are also buffer rods 9. Two buffer rods 9 are provided on the top of the bottom plate 1 away from the H-shaped support guide plate.

[0036] When the transverse transmission rack 52 is separated from the first transmission gear 54, the flip compacting plate 55 will return to its original position, and then the buffer rod 9 will buffer the impact force generated by the reset of the flip compacting plate 55.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com