Folding system of bottom plate and handrail combined structure

A folding system and combined structure technology, applied in the field of folding systems, can solve the problems of heavy workload, long time-consuming and high labor cost, and achieve the effects of long service life, convenient transportation and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

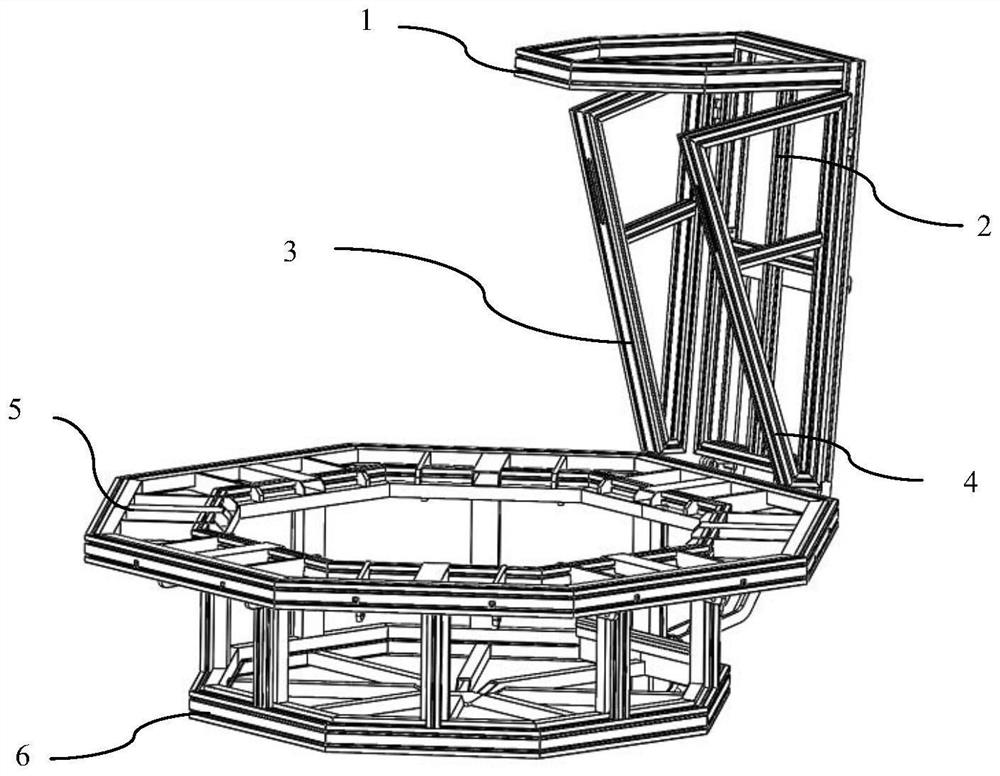

[0045] like Figure 1~6 As shown, a folding system of a base plate and railing combination structure in a preferred embodiment of the embodiment of the present invention includes an extension railing 1, an extension base plate 2, a fixed base plate 5, a sinking base plate 6, a linkage mechanism and a hydraulic cylinder 9, and the extension railing The lower part of 1 is rotatably connected with the upper part of the extension base plate 2 to form a set of extension mechanisms. The linkage mechanism is connected between the extension railing 1, the extension base plate 2, the fixed base plate 5 and the hydraulic cylinder 9 to move the hydraulic cylinder 9 linearly. This translates into the unfolding or folding motion of individual components in the system. In this embodiment, the link mechanism includes a first stretching mechanism 7 and a second stretching mechanism 8 .

[0046] in,

[0047]The fixed base plate 5 is a regular octagon placed horizontally, and eight stretching...

Embodiment 2

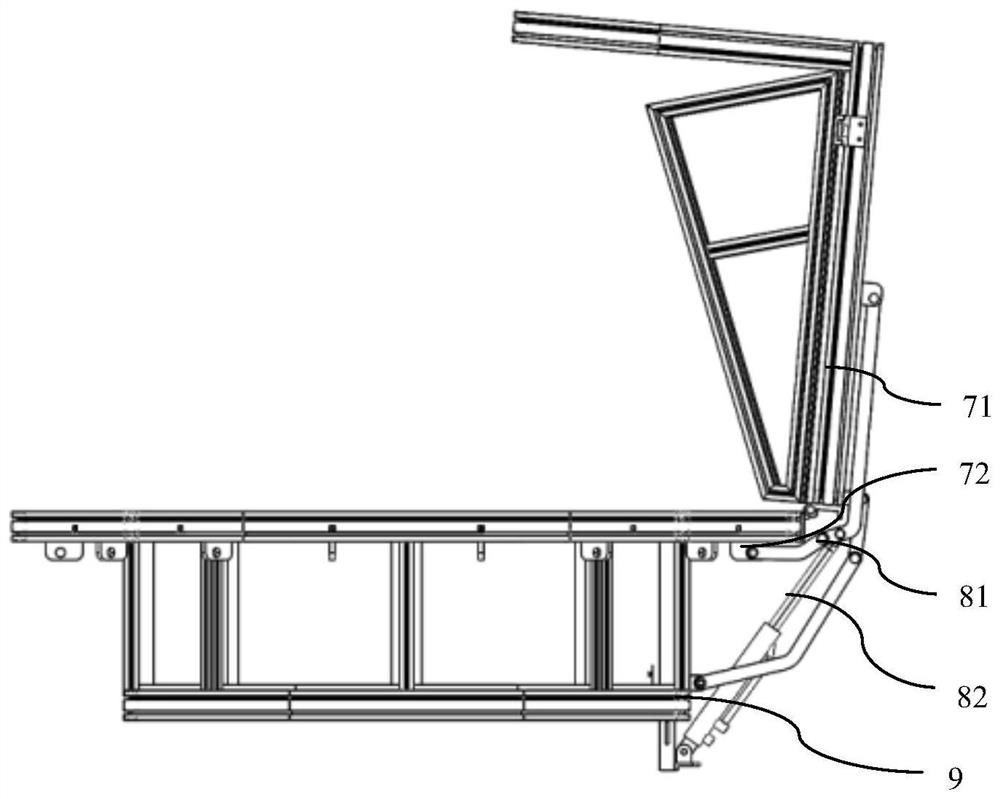

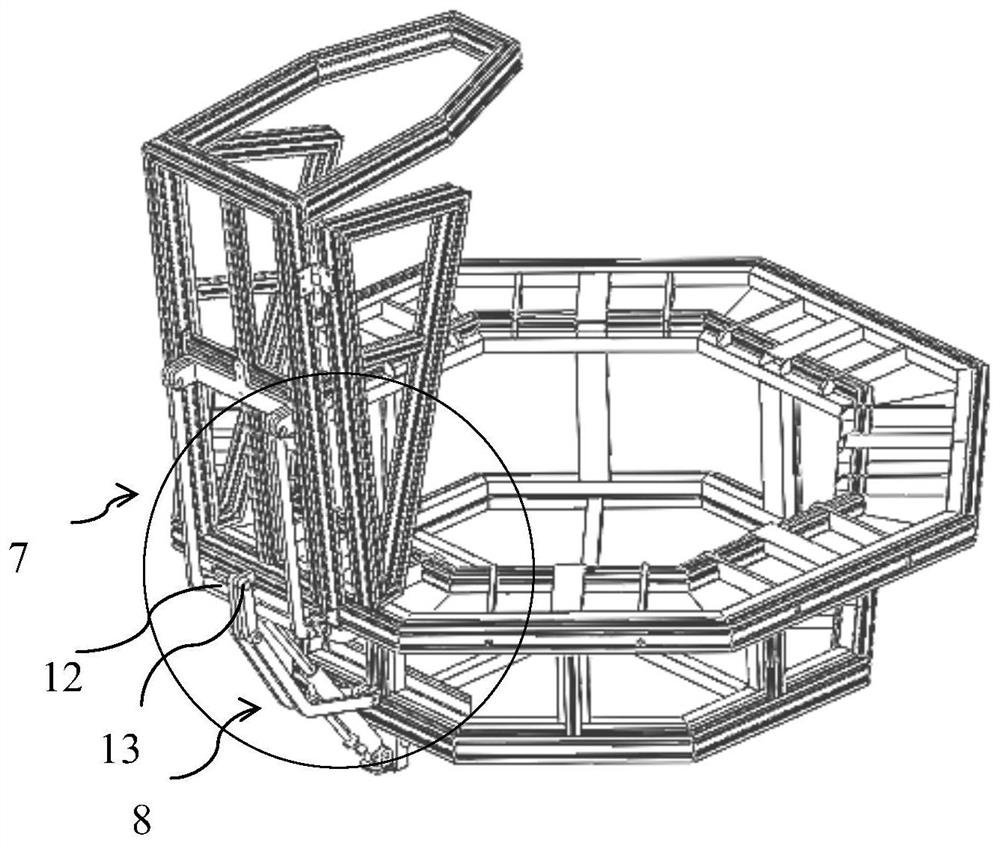

[0062] like Figure 7 , 8 As shown, a folding system of a combination structure of a bottom plate and a railing in a preferred embodiment of the embodiment of the present invention includes an extended railing 1, an extended bottom plate 2, a sinking bottom plate 6, a fixed bottom plate 5, a linkage mechanism and a hydraulic cylinder 9, and the extended railing The bottom of 1 is rotatably connected with the top of extension base plate 2 to form a set of extension mechanisms.

[0063] A first stretching mechanism 7 is arranged between the extension base plate 2 and the fixed base plate 5. The first stretching mechanism 7 includes a first left upper pull rod 71 and a first left pull rod 72 connected to each other, and a first right upper pull rod 73 and a first right upper pull rod connected to each other. The first right pull-down rod 74 . The first fixed shaft 12 is connected between the lower parts of the first left upper link 71 and the first right upper link 73 . The le...

Embodiment 3

[0072] No sinking floor 6

[0073] A folding system of a base plate and railing combination structure in a preferred embodiment of the embodiment of the present invention includes an extension railing 1, an extension base plate 2, a fixed base plate 5, a connecting rod mechanism and a hydraulic cylinder 9, the lower part of the extension railing 1 and the extension base plate 2 The upper part is rotatably connected to form a group of stretching mechanisms.

[0074] The difference from Embodiment 1 is that the fixed base 5 is not provided with a sinking base, the second stretching mechanism 8 is arranged between the stretch base 2 and the fixed base 5, and the thickness of the base of the system is reduced as much as possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com