Fabricated partition wall and partition and compartment manufactured by applying partition wall

A prefabricated and bulkhead technology, applied to walls, building components, buildings, etc., can solve the problems of complicated installation steps, time-consuming and labor-intensive work, and low work efficiency, and achieve the effects of convenient construction, improved installation efficiency, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

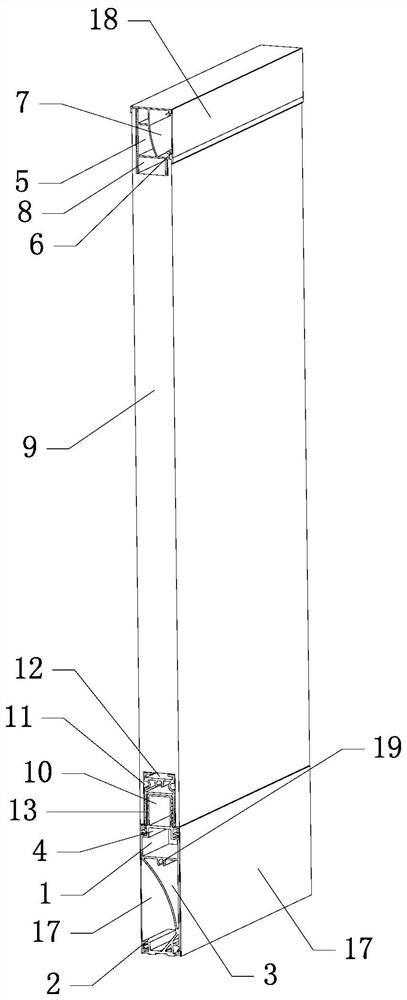

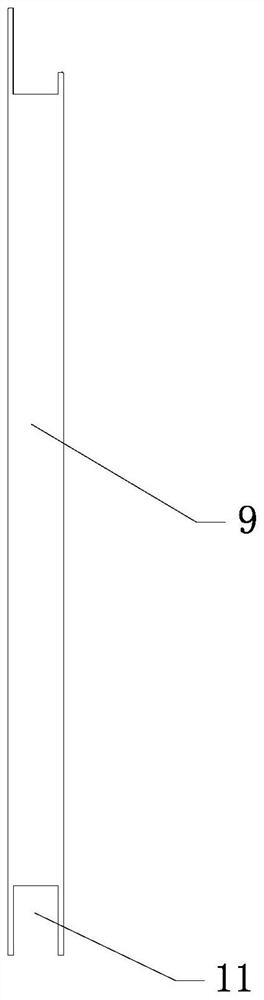

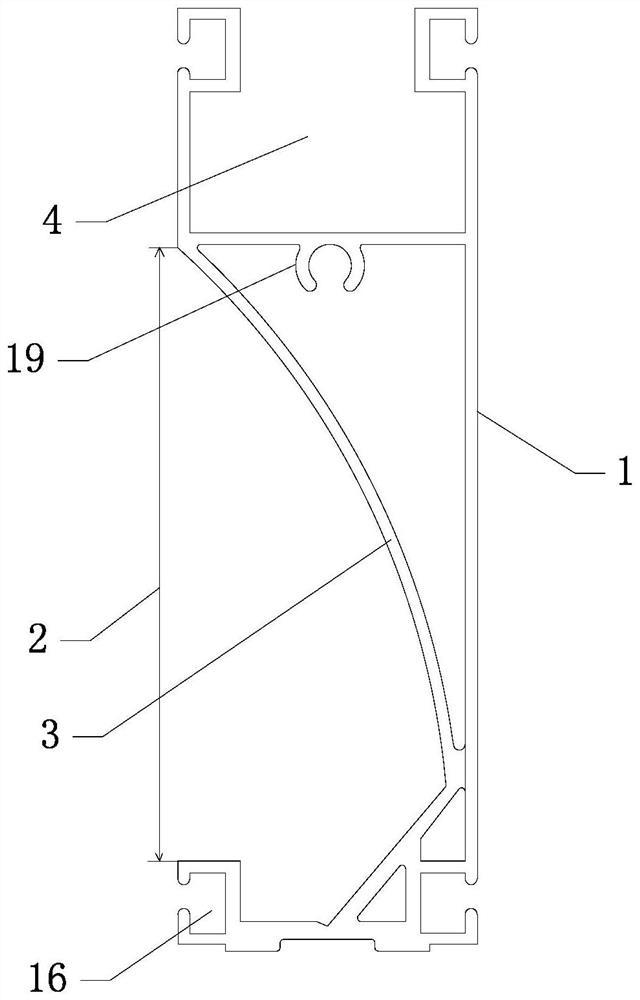

specific Embodiment 1

[0063] The partition wall can be assembled in the factory in advance according to the measurement data during the production process of the factory, and the modular installation on the construction site can be realized. When installing, place the vertical plate structure in the area that needs to be separated indoors, then use tools to pass through the lower installation groove 2 of the lower support keel 1, install and fix the lower support keel 1 on the ground with bolts and other fixings, and install the traditional A whole keel can be divided into several sections and divided into parts, and the installation of the partition wall can be completed without laying the whole keel, saving materials; then use tools to pass through the upper installation groove 6 of the upper support keel 5, and fix it with bolts, etc. The upper supporting keel 5 is installed and fixed on the roof by parts, which is convenient for later construction and greatly improves the efficiency of construct...

specific Embodiment 2

[0066] When it is necessary to divide the room into several areas, it can be realized by combining the partition structure and the vertical plate structure. When the partition structure needs to leave a gap up and down for installation, two L-shaped corner codes 23 can be fixed on the wall with bolts and other fixings at the position where the partition 21 needs to be installed on the wall, and then the other two L-shaped Corner code 23 is respectively installed on the side wall with vertical plate 9, makes the L-shaped corner code 23 of two layers up and down all be in same horizontal line. Then, the dividing plate 21 is installed on two L-shaped corner codes 23 on one side of the wall by bolts and other fixtures earlier, or installed on two L-shaped corner codes 23 on one side of the vertical plate 9 side walls. Finally, the vertical panel structure is pushed, so that the panel slots 22 at the four corners of the panel 21 are engaged with the L-shaped corner brackets 23 resp...

specific Embodiment 3

[0068] When the room needs to be divided into several open compartments, such as public toilets, fitting rooms, etc., a switch door 15 can be installed between the adjacent two vertical plate structures and the partition structure to further expand the scope of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com