Overhead power transmission line wire jumper hooking cable clamp semi-automatic replacement method

A technology of overhead transmission line and replacement method, applied in the field of semi-automatic replacement of overhead transmission line jumpers and hook clips, can solve problems such as unfavorable power grid stability, unsatisfactory combination gaps, damage, etc., to improve work efficiency and safety, promote The development of live work, the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

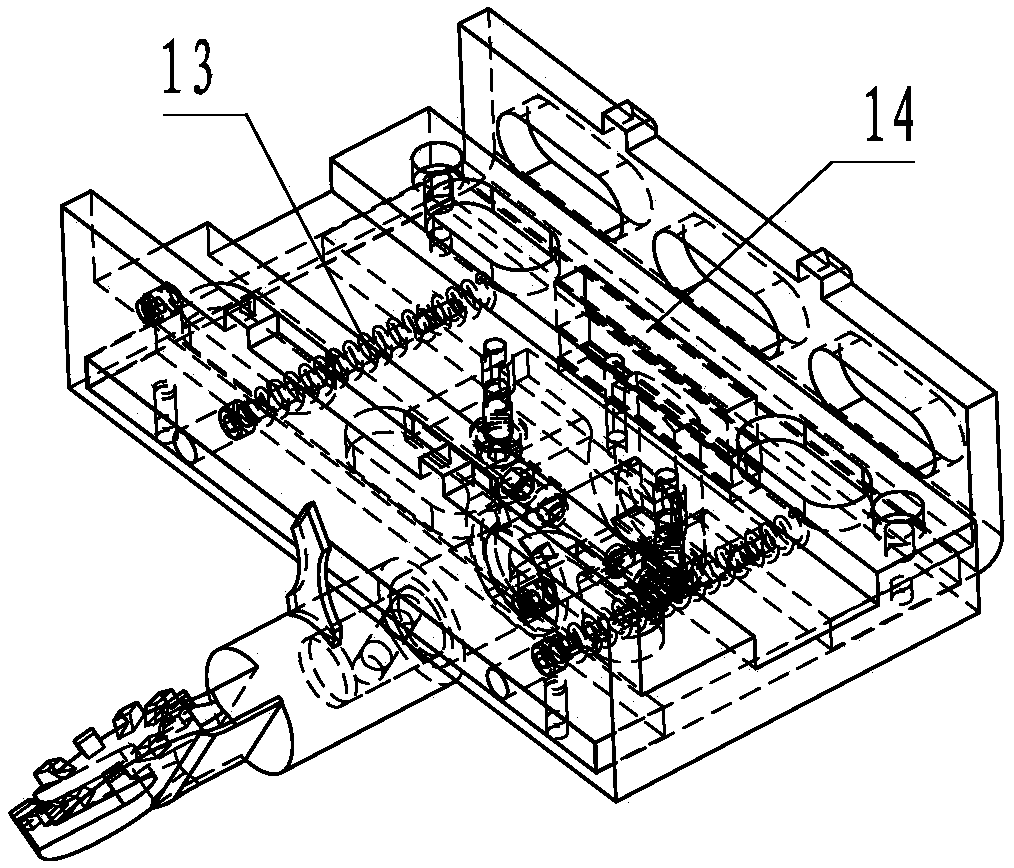

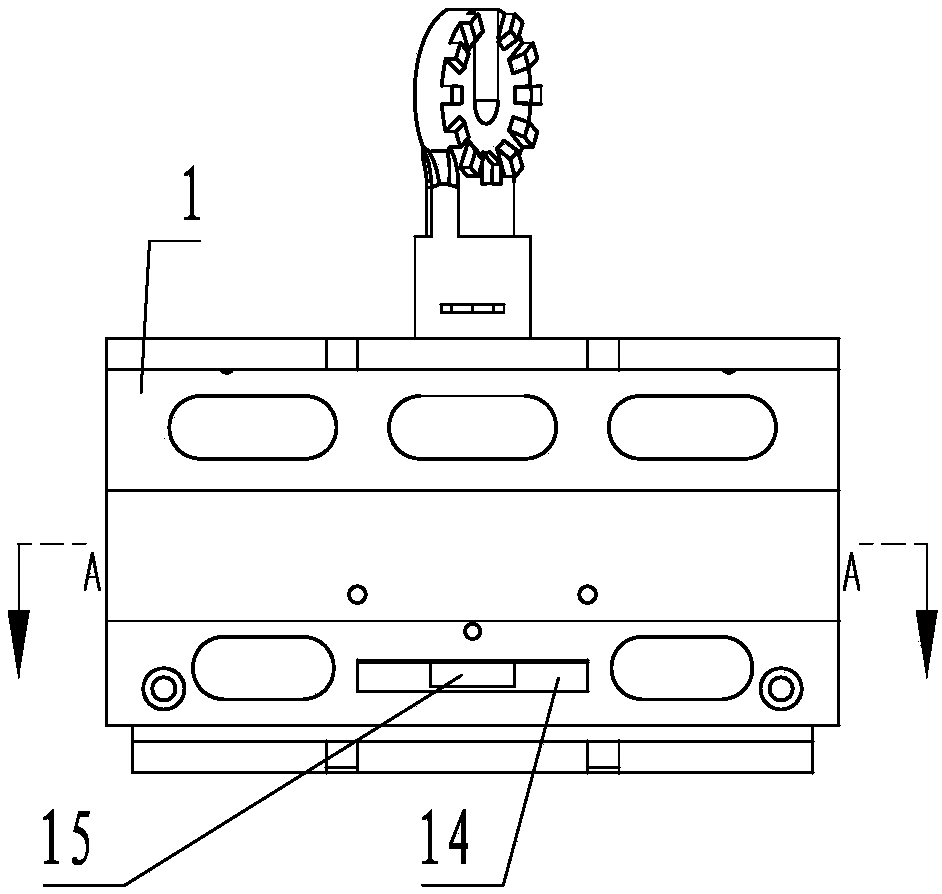

[0045] A method for semi-automatically replacing wire jumpers and hook clamps of overhead transmission lines, providing a replacement tool, including an elastic fixing device 1 for parallel hook clamps, a spring clamp 2 for cover plates of parallel hook clamps, a remote electric operation wrench, and a magnetic suction type sleeve 3;

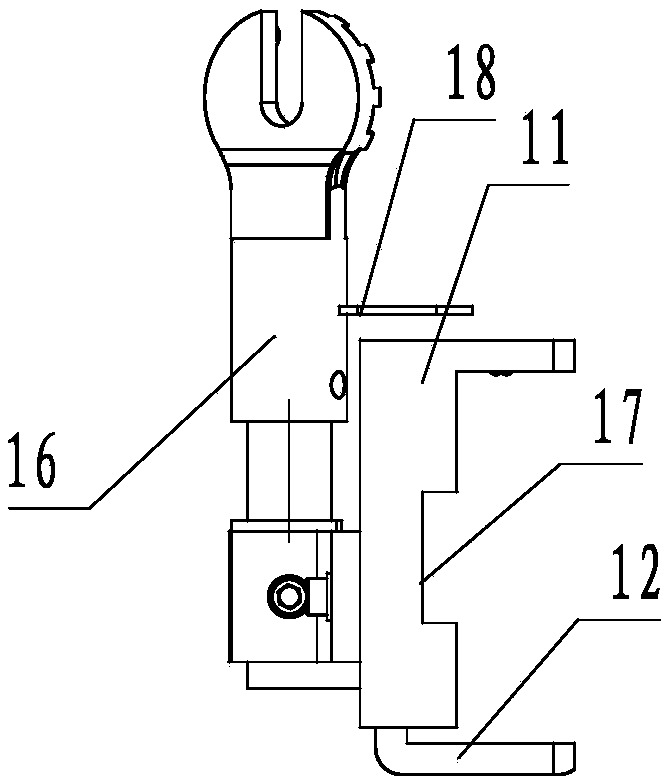

[0046]The elastic fixing device for hooking wire clips includes an L-shaped bottom plate 11 and an L-shaped splint 12, the L-shaped bottom plate and the splint are relatively set up to form a U-shaped groove structure, and the L-shaped bottom plate and the L-shaped splint are Arranged along the width direction of the U-shaped groove, the bottom edge of the bottom plate is a sandwich structure, and the bottom edge of the splint is inserted into the interlayer of the bottom edge of the bottom plate. The width of the bottom edge of the splint is smaller than the width of the bottom edge of the bottom plate. The sides are connected by spring 13, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com