A beam device for mounting ground testing equipment

A ground test equipment and beam technology, applied in the field of vehicles, can solve the problems affecting the overall space layout, single function, complex structure of the outrigger beam, etc., and achieve the effect of improving space utilization, facilitating processing and assembly, and facilitating replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

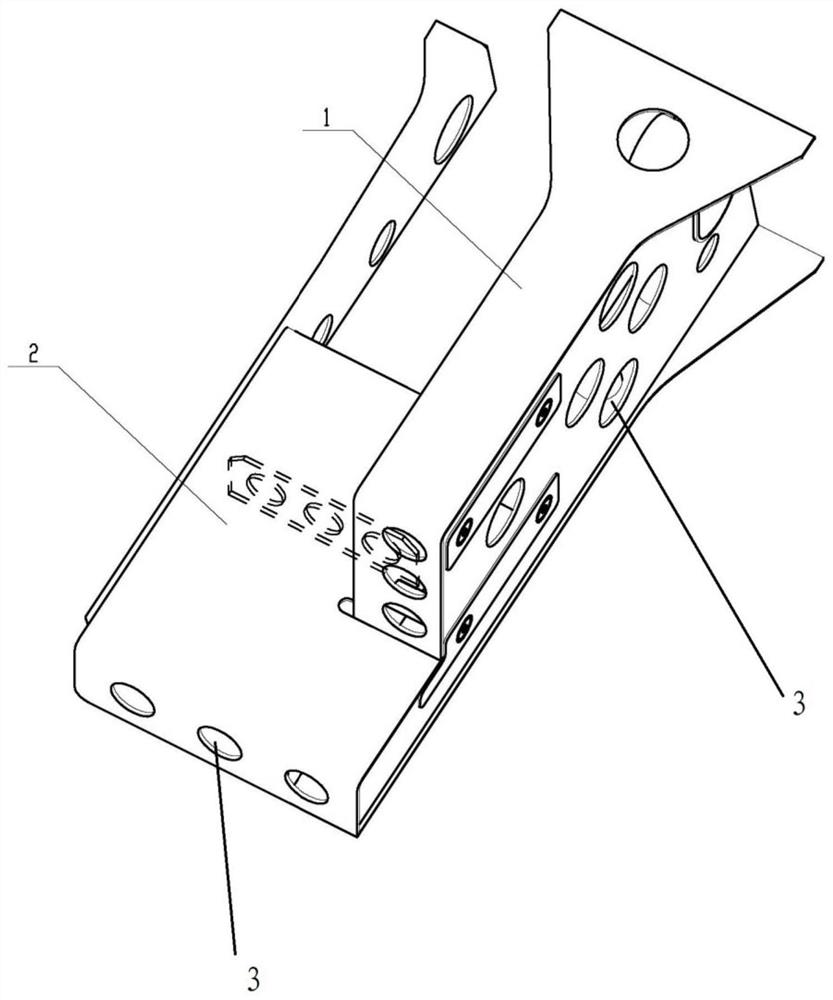

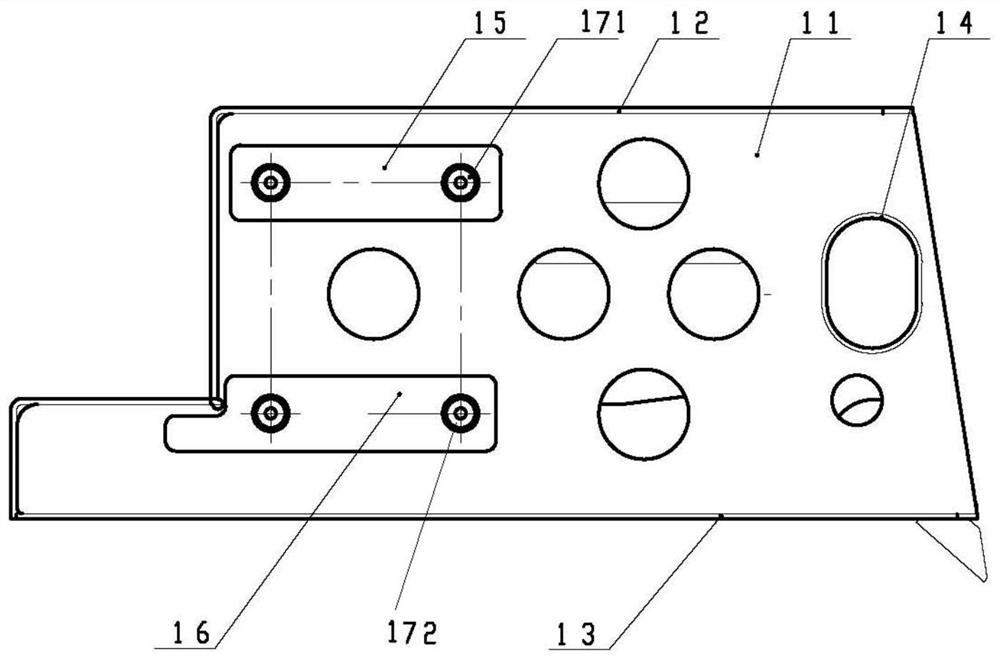

[0028] figure 1 It is a schematic structural diagram of a beam device for installing ground test equipment in the embodiment of the present invention, as shown in figure 1 shown:

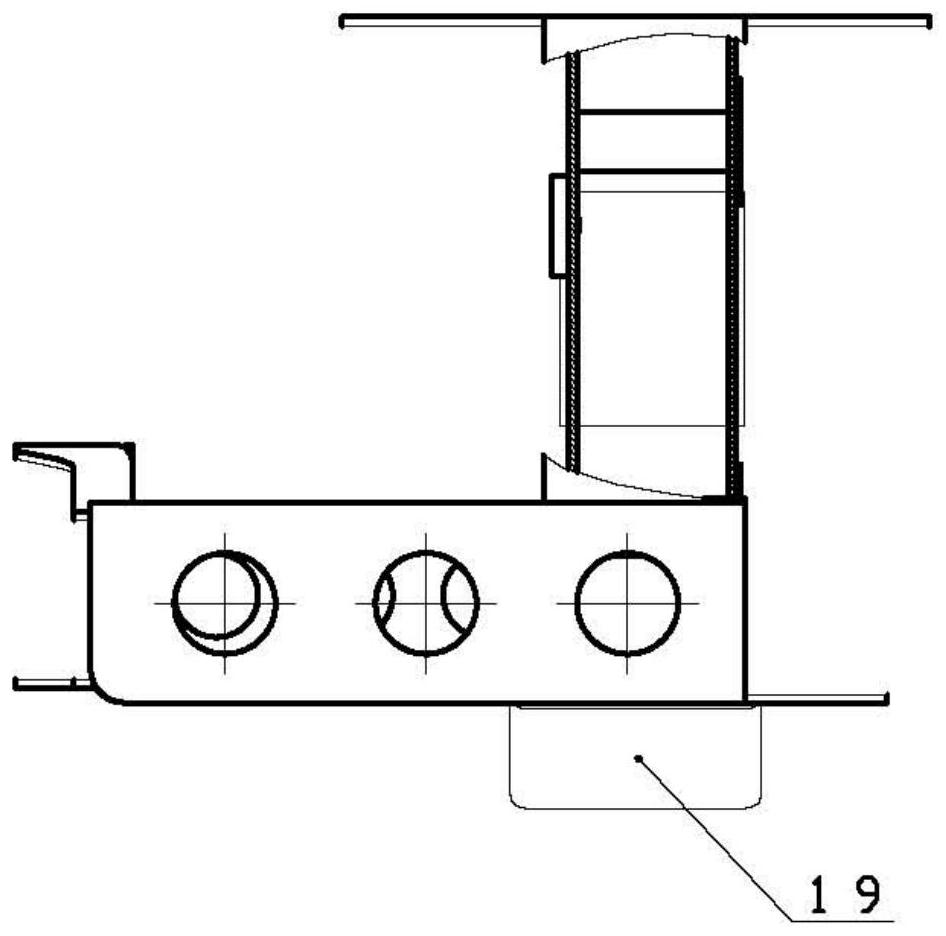

[0029] The beam device for installing ground testing equipment includes: a beam body 1, the beam body 1 includes: a bottom plate 13; a first vertical plate 11, the first vertical plate 11 is perpendicular to the bottom plate 13, and One side of the first vertical plate 11 is flush with the edge of the bottom plate 13; the second vertical plate, the second vertical plate is arranged in parallel with the first vertical plate 11; the cover plate 12, the The cover plate 12 is respectively fixedly connected to one end of the first vertical plate 11 and the second vertical plate away from the bottom plate 13 , and is formed by the bottom plate 13 , the first vertical plate 11 , the second vertical plate and the cover plate 12 . A accommodating space.

[0030] Further, a plurality of drainage holes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com