Differential mechanism

A differential and speed technology, applied in the field of vehicles, can solve the problems of high differential speed, affecting the service life of the differential, and high temperature damage of the differential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the differential according to the present invention will be described below with reference to the accompanying drawings. The following detailed description and drawings are used to illustrate the principles of the present invention. The present invention is not limited to the described preferred embodiments, and the protection scope of the present invention is defined by the claims.

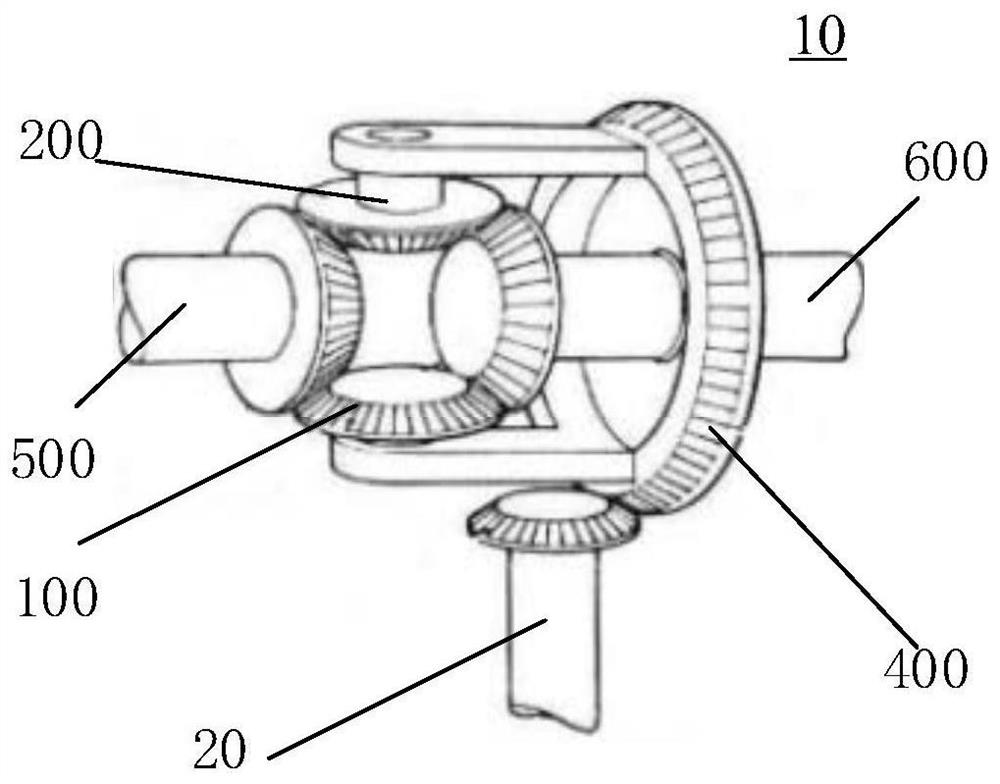

[0022] figure 1 A differential according to an embodiment of the invention is shown. Refer to the following figure 1 A differential according to an embodiment of the present invention is described.

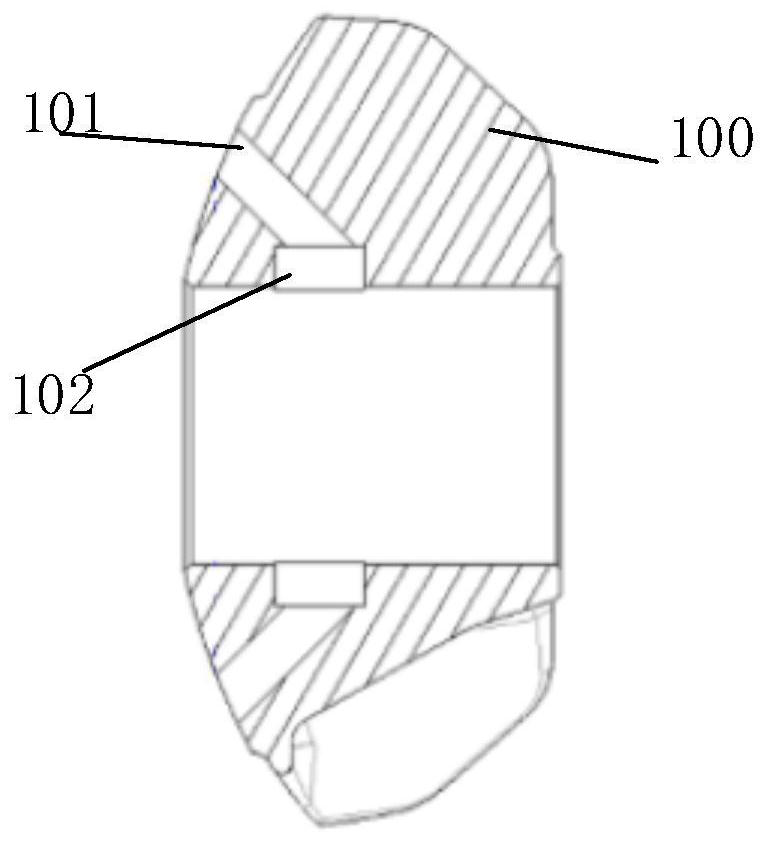

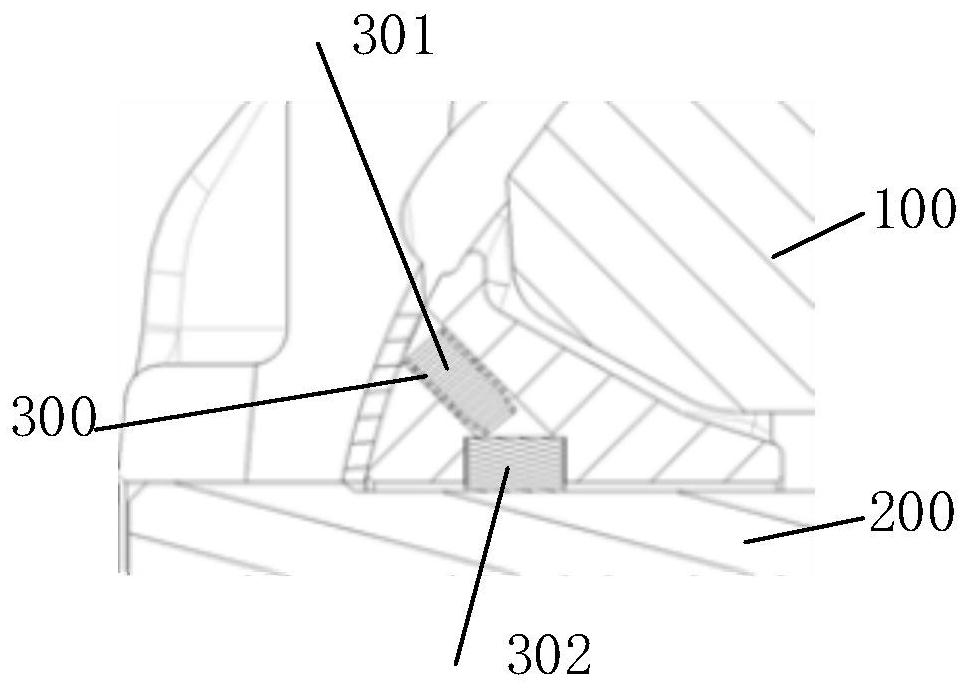

[0023] Such as figure 1 As shown, the differential 10 includes two planetary gears 100 , a left side gear 500 , a right side gear 600 and a carrier 400 . The power is transmitted to the gear carrier 400 in the differential 10 through the input shaft 20, and the gear carrier 400 drives the two planetary gears 100 to rotate through the planetary gear shaft 200,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com