Glass unit having sliding groove and method for manufacturing same

A technology of glass and components, applied in the field of glass units with sliding grooves and used in the manufacture of glass units, which can solve problems such as difficulty in disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

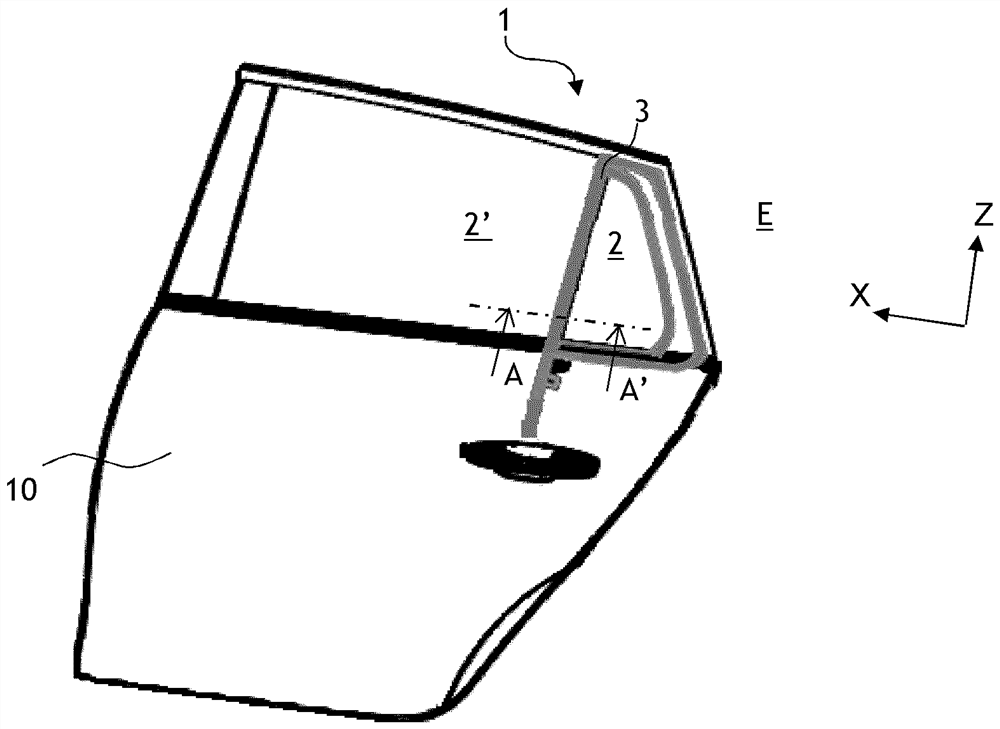

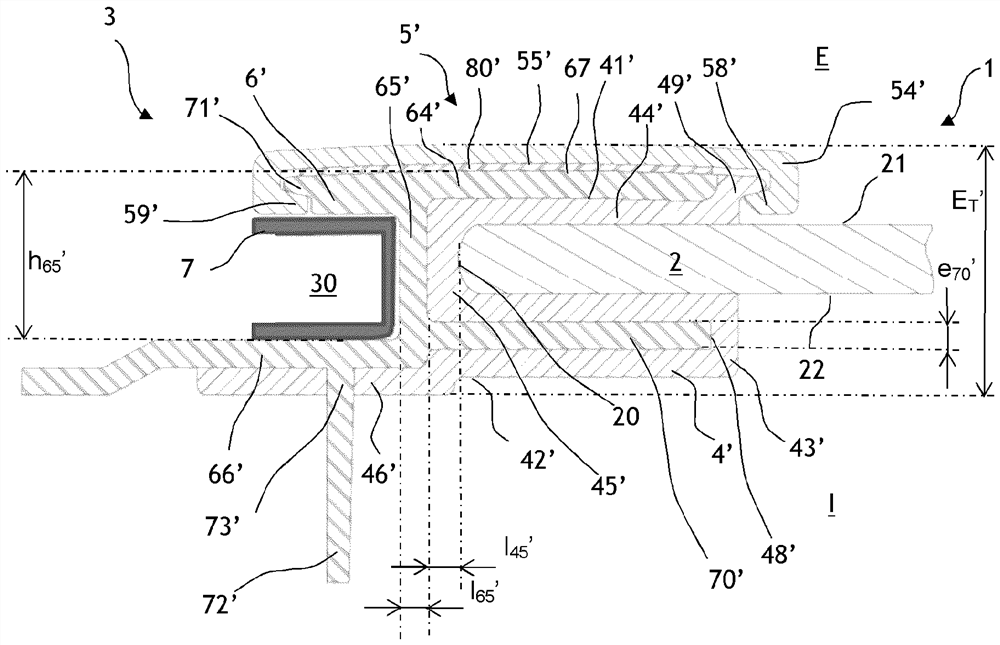

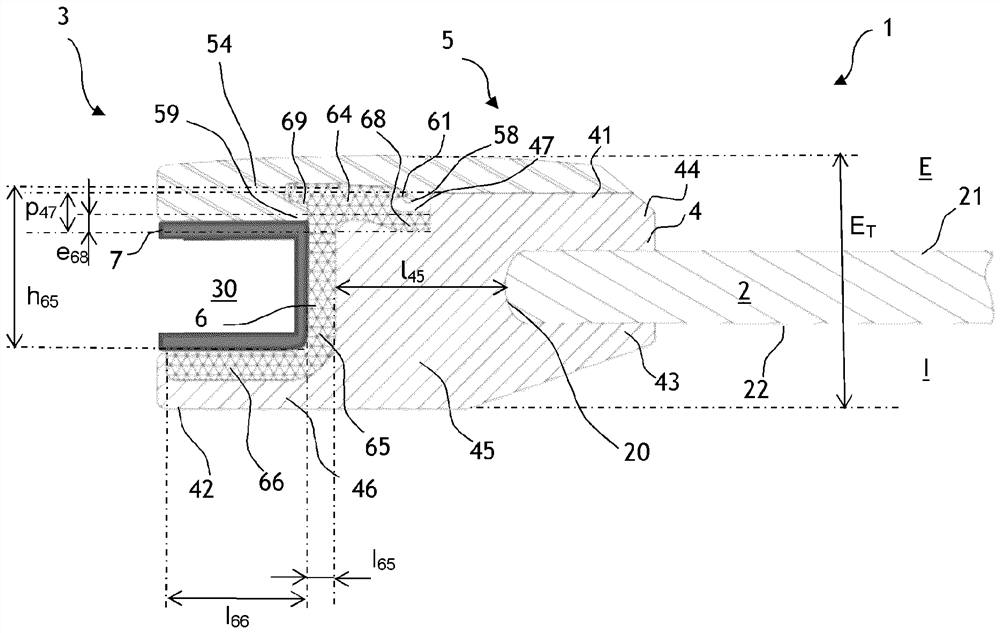

[0053] In these figures, individual elements in each figure are drawn to scale, but background elements are generally not shown in order to make the figures easier to study. Furthermore, for figure 1 , figure 2 and image 3 The reference numerals of the common elements are unchanged, and therefore these reference numerals remain the same in these figures. In the scope of this document, the concepts of "centripetal" and "central" should be figure 1 Considered in the plane of the sheet in , expressed along the X and Z axes relative to the center of the glass unit; the centripetal direction is towards this center and the centrifugal direction is away from this center.

[0054] The present invention relates to glass units 1, and in particular to figure 1 Vehicle glass unit as seen in . This glazing unit comprises a fixed glass element 2 forming a separation between the outer space E and the inner space I, and having an upright 3 sitting along the lateral edge of the fixed gl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap