Non-electric driving type self-rotating copper hot pot

An electric-driven, self-rotating technology, which is applied to cooking utensils with water bath devices, cooking utensils, household appliances, etc., can solve problems such as boiling soup to the bottom, high cost of use, and affecting the user's eating experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

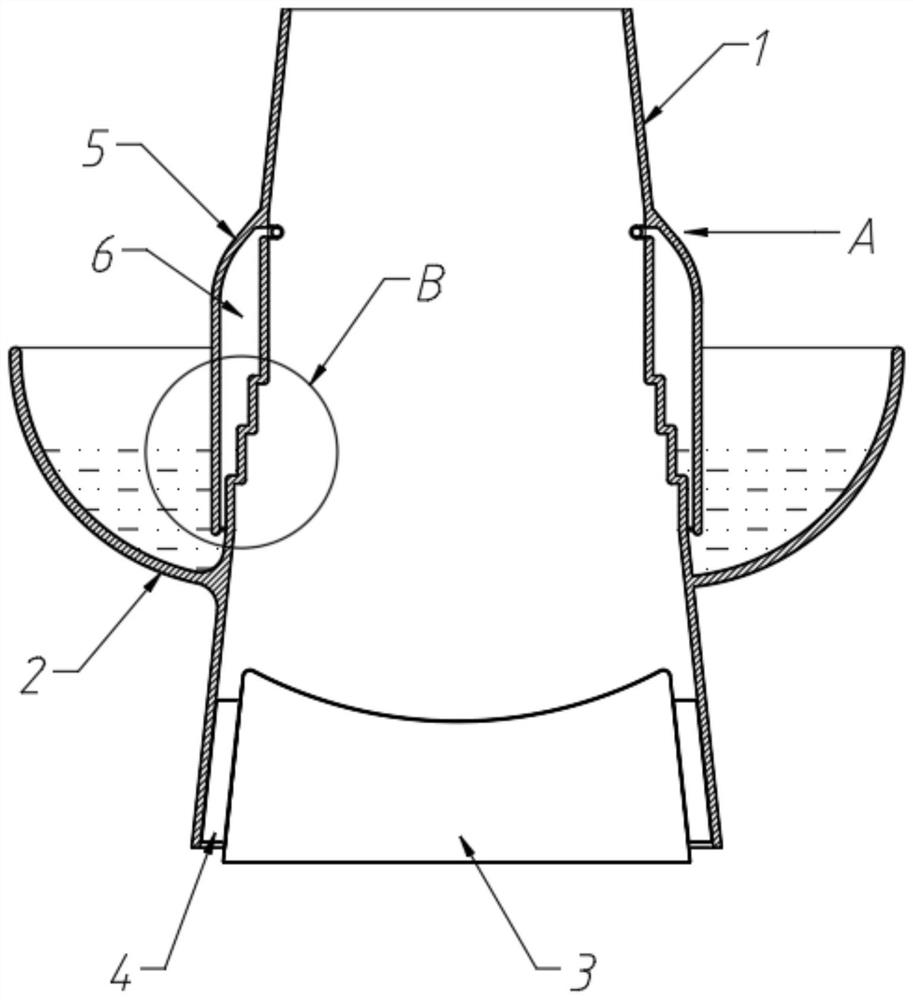

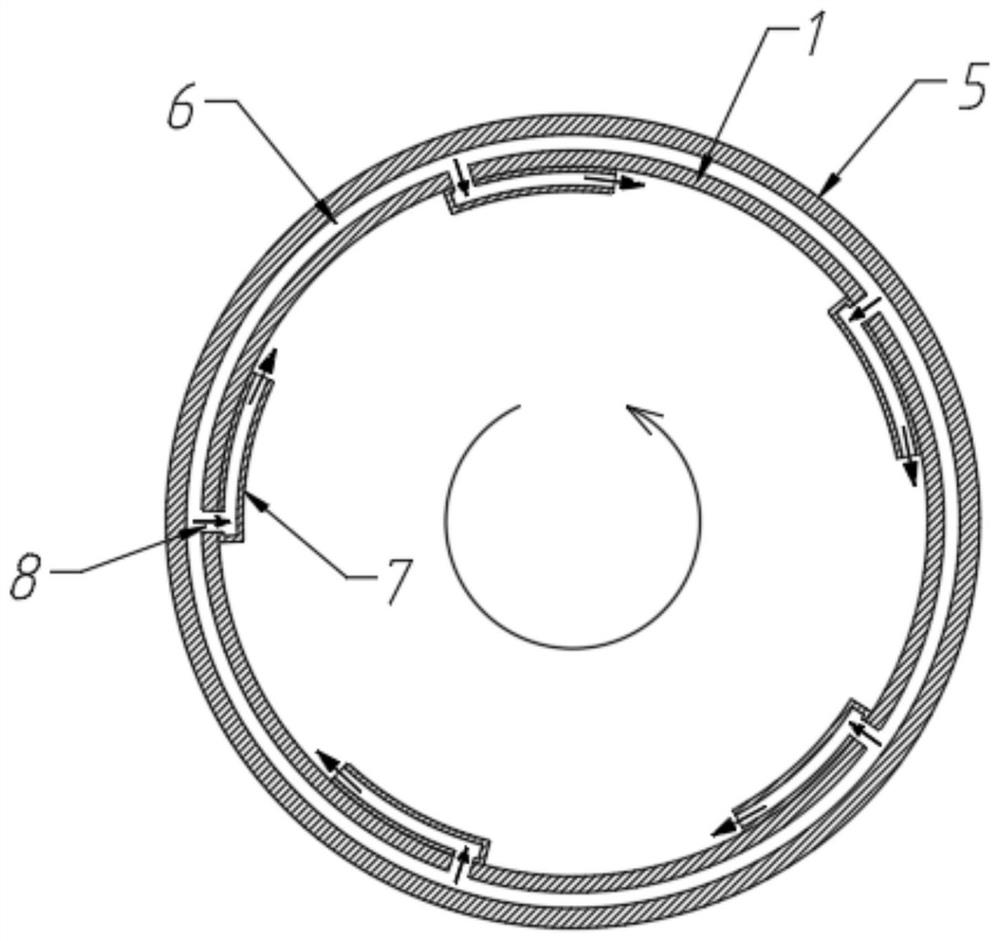

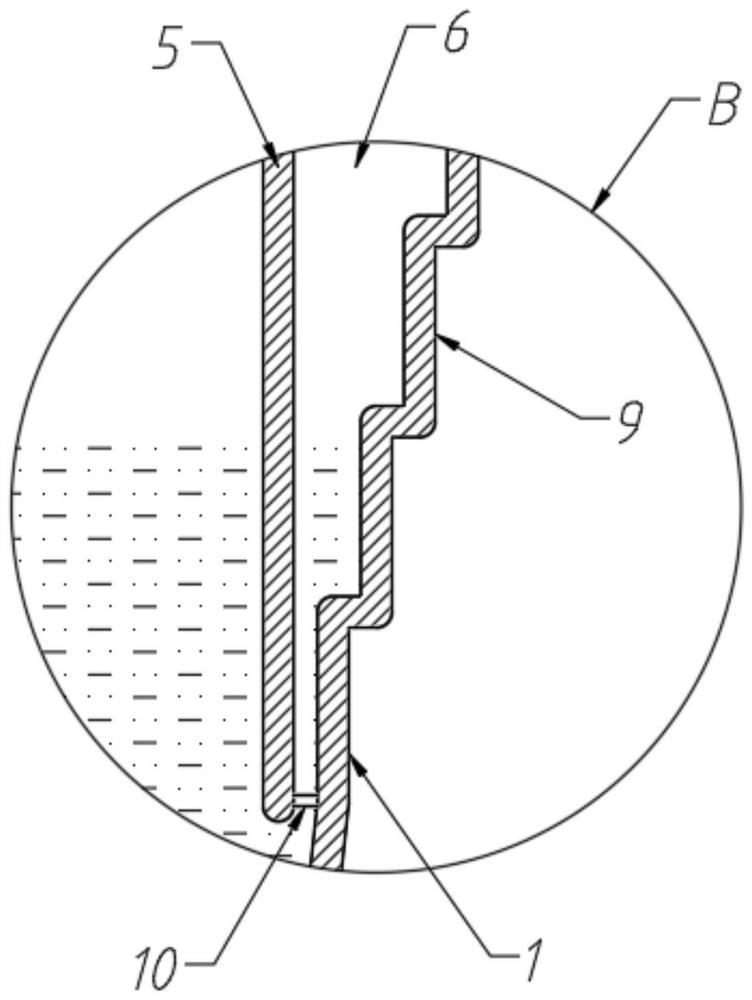

[0024] refer to Figure 1-3 , a non-electrically driven self-rotating copper hot pot, including a mounting base 3, an inner cylinder 1, an outer basin 2 and a separating cylinder 5, wherein the mounting base 3 is used to place a heat source that provides heat, and the heat source is a charcoal fire or an electric heating device The lower end of the inner cylinder 1 is rotated and arranged on the mounting seat 3, and the middle part of the inner cylinder 1 is a partition 9; the outer basin 2 is used to place heated food, and the outer basin 2 is sleeved on the outer wall of the inner cylinder 1 with the opening facing upwards. 2. The horizontal height is matched with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com