Special grinding machine for removing welding spots of iron handicrafts

A handicraft and grinding machine technology, which is applied in the direction of abrasive jet machine tools, used abrasive processing devices, abrasives, etc., can solve the problem of labor-intensive manual rotation, and achieve the effect of reducing repeated pushing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

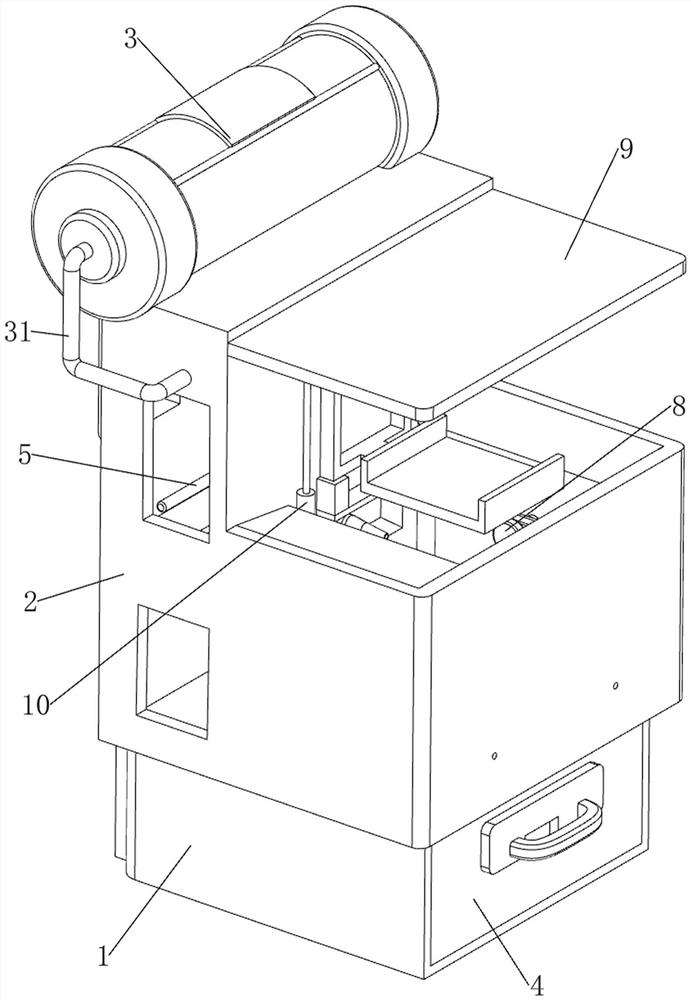

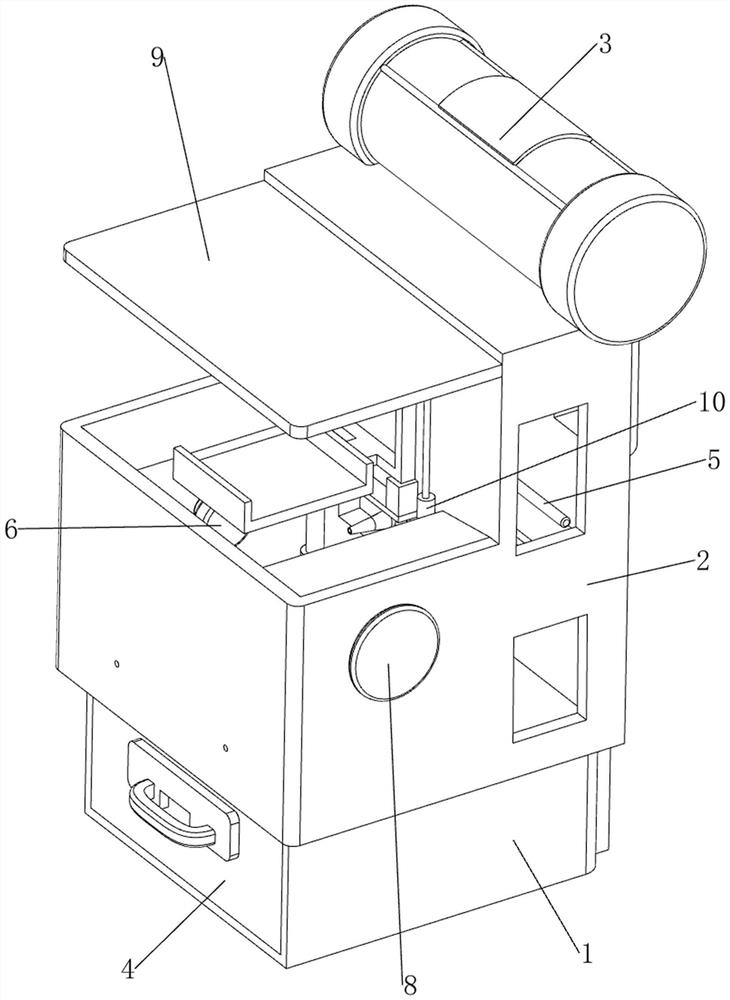

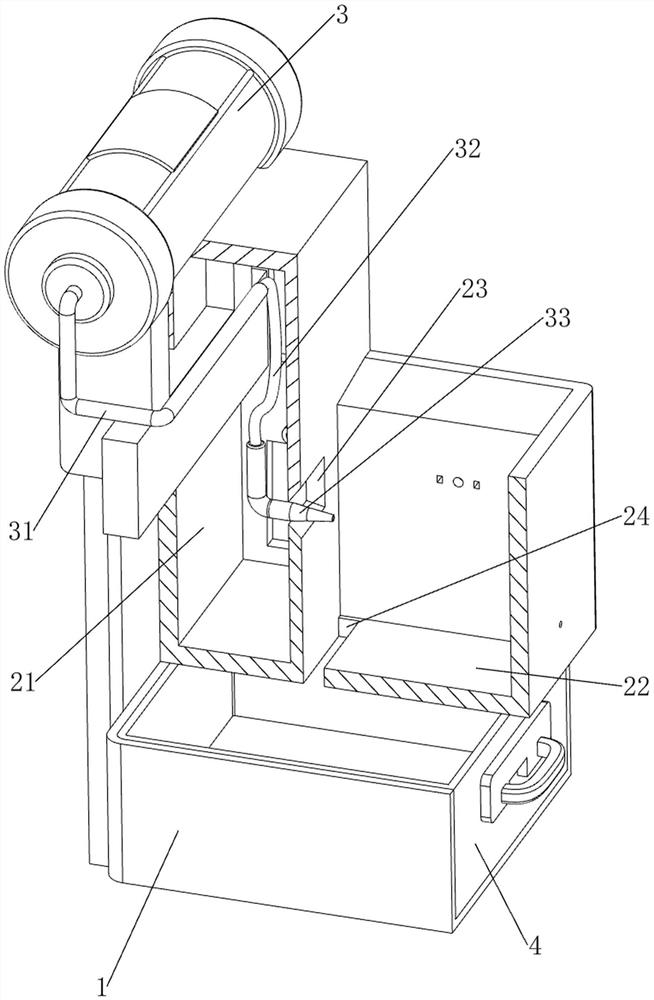

[0031] A special grinding machine for removing solder joints of iron handicrafts, now for reference Figure 1-6 , including a base 1, an installation box 2, a sand blaster 3, a conduit 31, a hose 32, a nozzle 33, a collection box 4, a sandblasting mechanism 5 and a rotating mechanism 6, the upper side of the base 1 is provided with an installation box 2, and the installation box 2. It includes an outer box 21 and an inner box 22. An outer box 21 is provided on the upper left side of the base 1. An inner box 22 is connected between the right side of the outer box 21 and the base 1. A sandblasting groove 23 is opened on the lower side of the right side of the outer box 21. , the left side of the lower part of the inner box 22 has a sand outlet 24, the upper left side of the outer box 21 is provided with a sand blaster 3, the top of the sand blaster 3 is provided with a cover, and the base 1 is slidingly provided with a collection box 4, the collection box 4 For collecting sand, ...

Embodiment 2

[0036] On the basis of embodiment 1, now refer to Figure 7 , also includes a reciprocating mechanism 7, the reciprocating mechanism 7 includes a first rotating shaft 71, a spur gear set 72, a second rotating shaft 73, a transmission belt 74, a space cam 75 and a guide sleeve 76, and the right side of the inner box 22 is rotated. There is a first rotating shaft 71, the first rotating shaft 71 is rotationally connected with the support frame 61, a spur gear set 72 is connected between the first rotating shaft 71 and the transmission shaft 63, the spur gear set 72 includes two spur gears, the first rotating shaft 71 Spur gears are arranged on the transmission shaft 63, and the two spur gears are meshed. A second rotating shaft 73 is provided on the lower side of the outer box 21 to rotate to the left. The second rotating shaft 73 is provided with a space cam 75. The second rotating shaft Between 73 and the first rotating shaft 71, a transmission belt 74 is wound around the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com