Stamping die for trundle support

A technology for stamping dies and casters, applied in the field of stamping dies, can solve the problems of difficult guarantee of product quality stability, cumbersome processing procedures, etc., and achieve the effect of saving processing procedures, saving processing personnel, and eliminating material flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

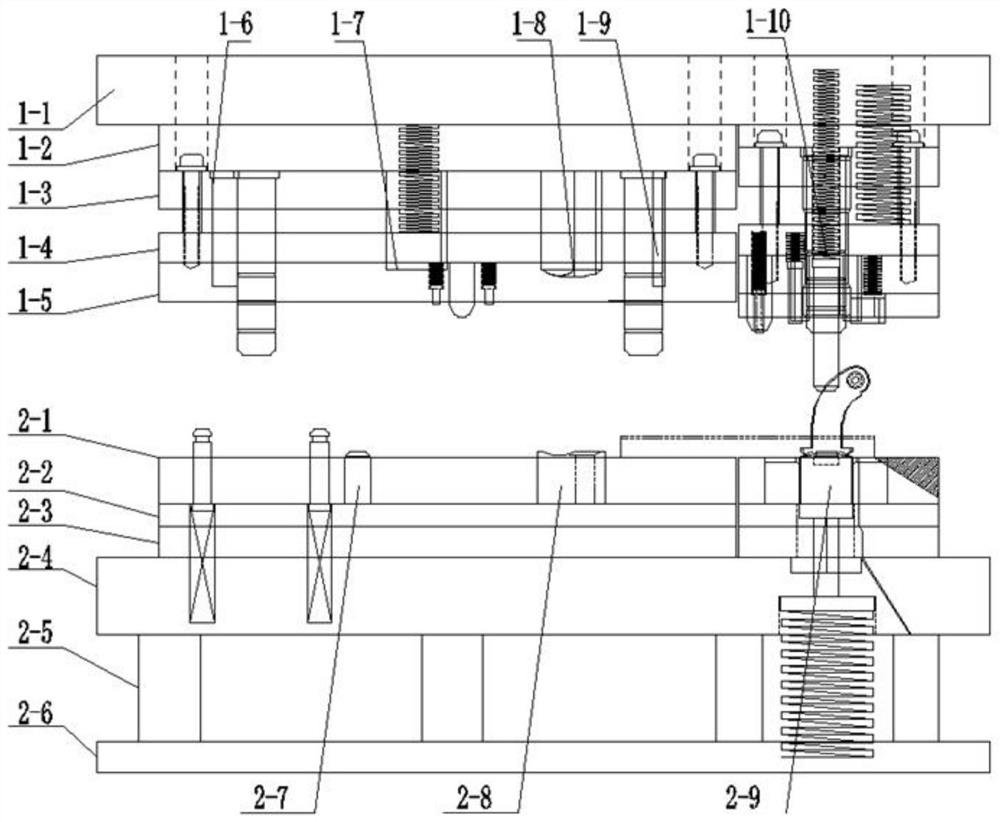

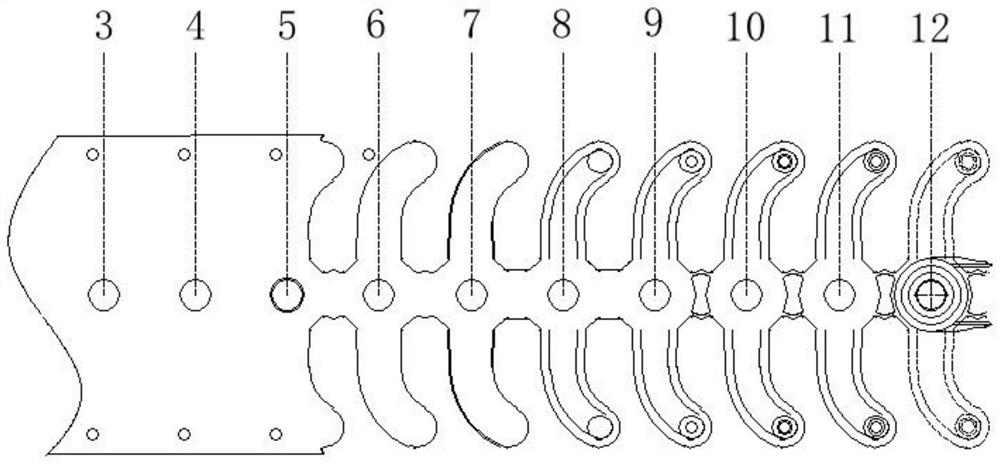

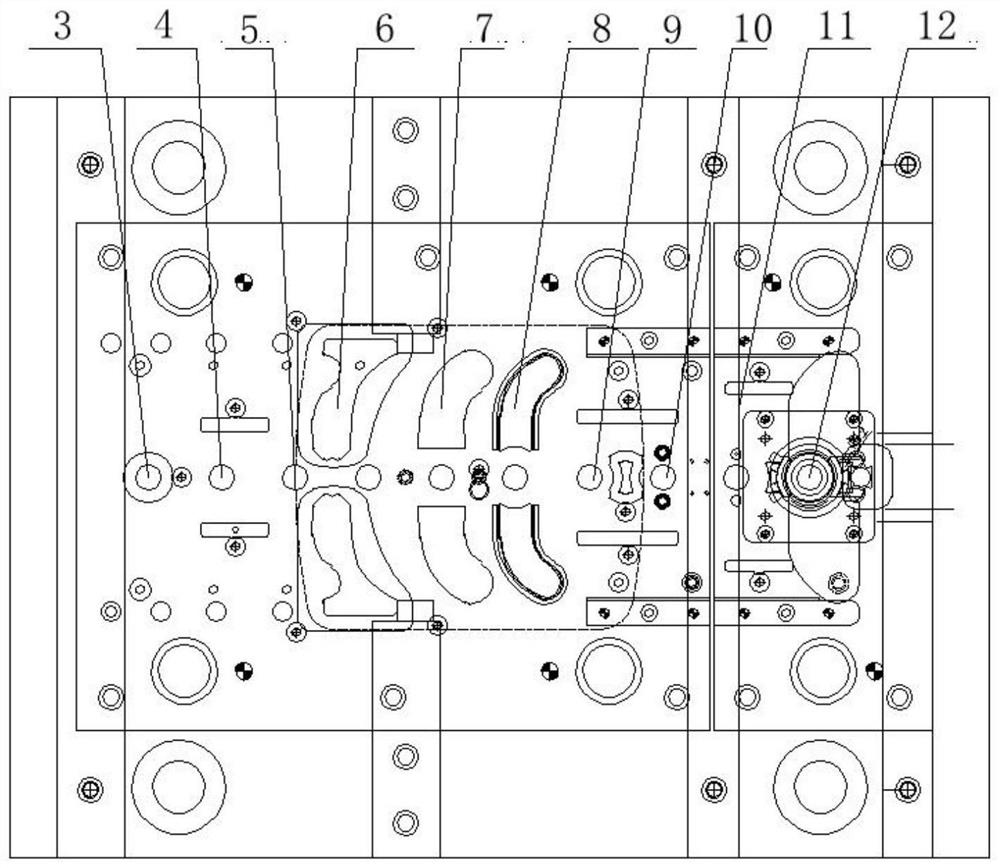

[0021] Such as Figure 1-3 As shown, a stamping die for a caster bracket includes an upper mold assembly and a lower mold assembly connected in sequence, and the upper mold assembly and the lower mold assembly include punching holes connected in sequence from left to right Process inserts, first empty step process inserts, first hole chamfering process inserts, material cutting process inserts, second hole chamfering process inserts, arc pressing process inserts, punching process inserts, third Hole chamfering process inserts, second empty step process inserts and blanking forming process inserts.

[0022] The upper die base includes an upper di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap