Printing device and method and printer

A technology for printing devices and printing media, applied in printing devices, printing and printing of special varieties of printed matter, can solve the problems of narrow application range of RFID tags, inaccurate reading and writing, complicated operation, etc., and achieve simple structure, easy reading and writing Accurate, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

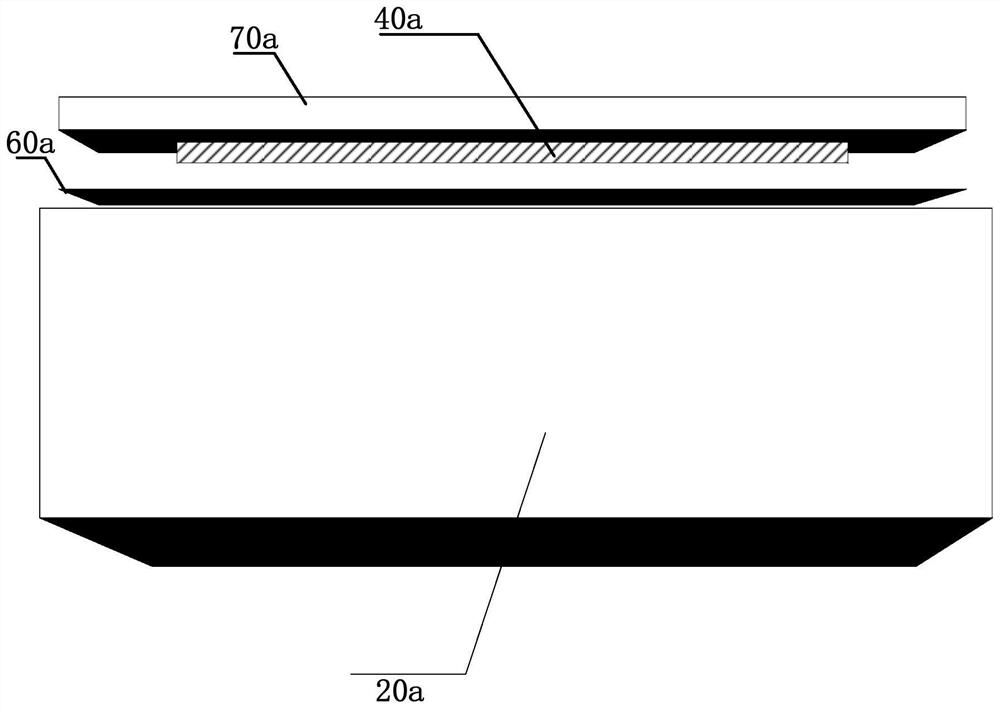

[0054] see figure 1 , an embodiment of the present invention provides a printing device, including:

[0055] The printing transmission mechanism 20a is used to convey the printing medium 60a including the radio frequency identification label, and the printing medium includes several sections of printing areas;

[0056] A printing unit 70a, configured to print on the printing surface of the printing medium 60a in the target printing area;

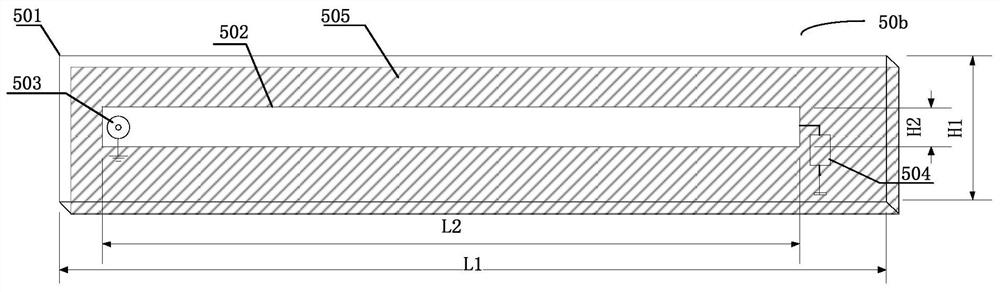

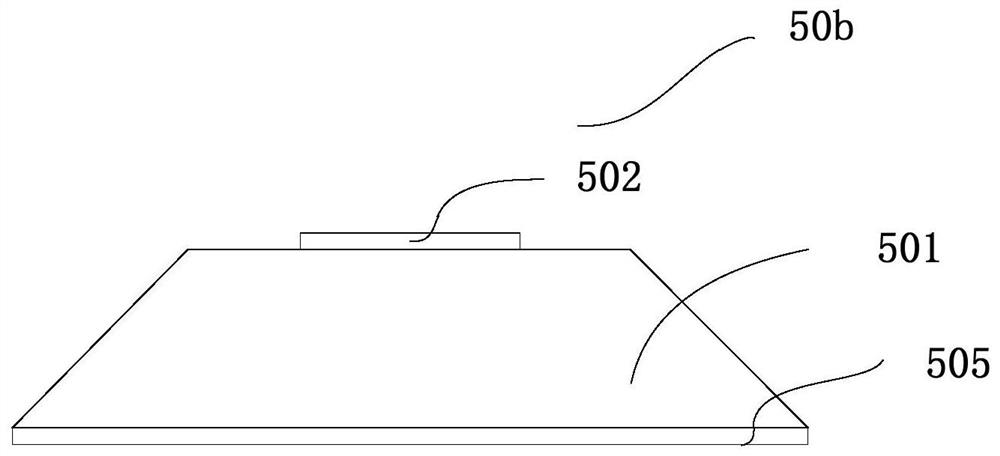

[0057] The radio frequency tag reading and writing execution unit 50a is arranged on the side of the printing unit 70a close to the printing surface, and is used to read and write the radio frequency identification tag in the printing medium;

[0058] The printing transmission mechanism is also used for sending the printing medium in the target printing area away from the printing unit if the printing and reading and writing of the radio frequency identification label are completed. Optionally, the radio frequency identification label is p...

Embodiment 2

[0136] This embodiment also provides a printing method, which is applied to the printing device in any of the above embodiments, see Figure 13 include:

[0137] S1301: Obtain a printing medium including a radio frequency identification label;

[0138] S1302: Control the printing unit to print on the printing surface of the printing medium;

[0139] S1303: Obtain radio frequency reading and writing information, and control the radio frequency tag reading and writing execution unit to read and write the radio frequency identification label in the printing medium according to the radio frequency reading and writing information;

[0140] S1304: If the printing and reading and writing of the radio frequency identification tag are completed, the printing medium conveyed to the target printing area leaves the printing unit.

[0141] Optionally, the printing medium includes several segments of printing areas.

[0142] In some embodiments, the printing method also includes:

[014...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com