Packaging process for achieving carton-free packaging

A process and carton technology, applied in the field of packaging without carton packaging, can solve the problems of waste of resources, broken cartons, and inability to re-use, to prevent waste of resources, solve waste of paper, and improve the stability of the packaging process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

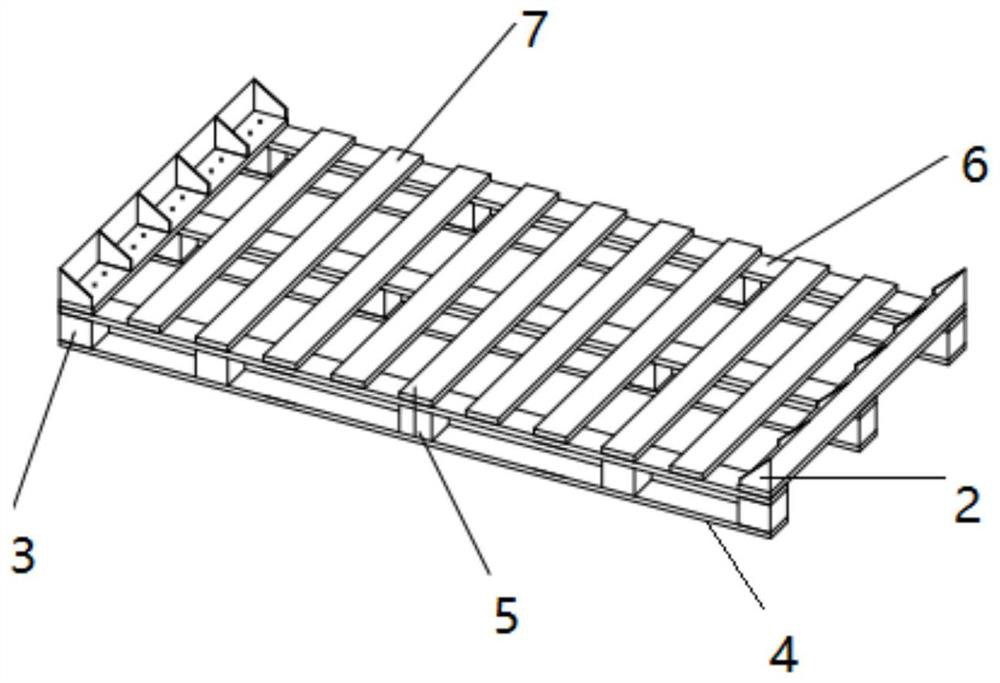

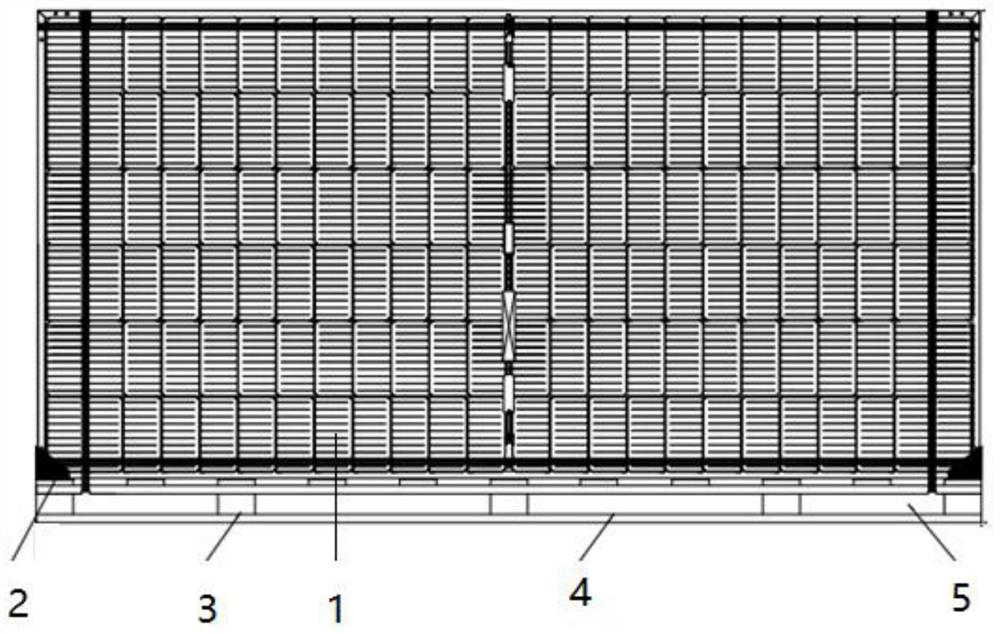

[0075] see figure 1 , the present invention provides a technical solution:

[0076] A packaging process for realizing cartonless packaging, comprising:

[0077] Packaging is carried out through a packaging structure, the packaging structure includes: a component fixing device, a plurality of piers 3 are arranged at the lower end of the component fixing device, and a component 1 is installed at the upper end of the component fixing device;

[0078] Pull-down bar 4, said pull-down bar 4 is installed at the lower end of said pier 3;

[0079] The upper end of the component fixing device is symmetrically provided with a plurality of card slots 2 on opposite sides;

[0080] A packing belt 5 is arranged on the peripheral side of the pier 3 and the pull-down strip 4;

[0081] Said packaging by packaging structure includes the following steps:

[0082] First place the card slot 2 on the component fixing device, and fix and install the component 1 through the card slot 2; finally wr...

Embodiment 2

[0086] see figure 1 , on the basis of embodiment 1, the present invention provides a kind of technical scheme:

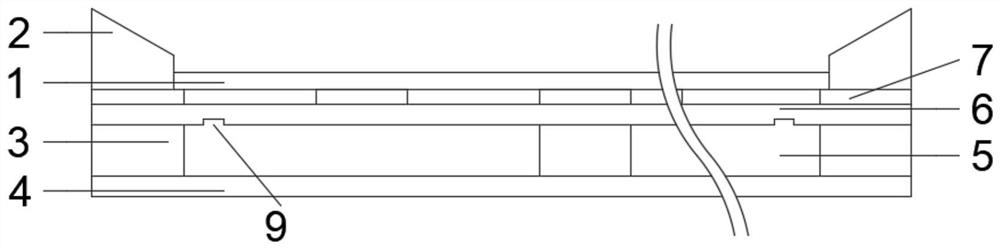

[0087] Between the clamping groove 2 and the vertical wood material 7; between the pier 3 and the lower bar 4;

[0088] The beneficial effects of the above-mentioned technical solution are as follows: the nail 8 is used to fix the connection between the card slot 2 and the vertical board wood 7; between the pier 3 and the pull-down bar 4; The device stability of the packaging process for realizing the cartonless packaging improves the stability of the packaging process for realizing the cartonless packaging.

Embodiment 3

[0090] see figure 1 , on the basis of embodiments 1 and 2, the present invention provides a technical solution:

[0091] In the aforementioned packaging process for realizing cartonless packaging, a buckle 9 is provided on the lower side of the upper pull bar 6 close to the slot 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com