Adhesive, and artificial board prepared by using same

A technology for adhesives and wood-based panels, applied in adhesive types, vinyl ether copolymer adhesives, adhesives, etc., can solve problems such as energy consumption, easy aging of boards, and formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0134] The preparation method of wood-based panel

[0135] Another aspect of the invention relates to a method of producing wood-based panels, said method comprising the use of the adhesive of the invention.

[0136] According to one embodiment of the invention, the method comprises pressing the mixture of lignocellulosic material and the binder of the invention at a temperature of 105-300° C. and a pressure of 0.4-10 MPa, preferably for 2-60 minutes, more preferably pressing for 3-30 minutes, such as 5-30 minutes.

[0137] The mixture of lignocellulosic material and binder of the invention for pressing can be prepared by mixing lignocellulosic material with the binder of the invention. When the binder is solid, the binder may first be dissolved in water before mixing with the lignocellulosic material.

[0138] Prior to pressing, it is preferred to remove some of the moisture in the mixture of lignocellulosic material and binder, for example to reduce the moisture content ...

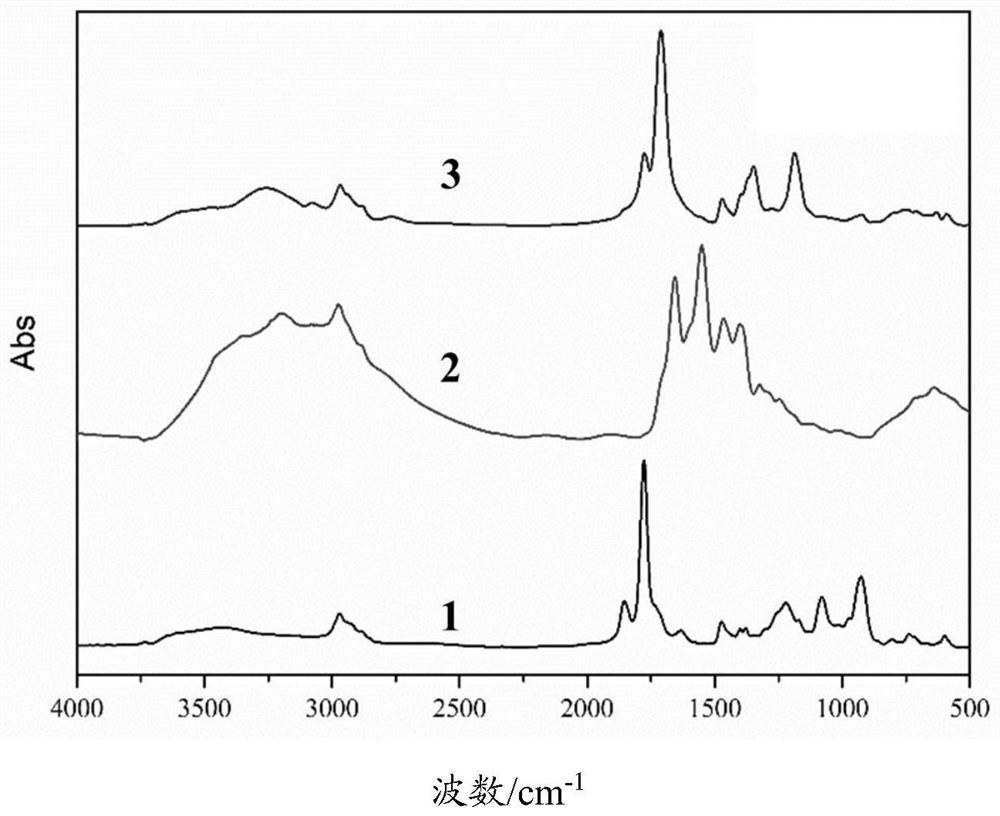

Embodiment 1

[0148] According to the mass parts, 13 parts of styrene, 12.25 parts of maleic anhydride, 300 parts of ethyl acetate and 0.2 parts of AIBN were mixed and dissolved, and the system was reacted at 70° C. for 6 hours after passing nitrogen gas for 20 minutes. After the product is precipitated with 400 parts of ethanol, it is centrifuged, washed three times with sherwood oil, and dried to obtain the styrene-maleic anhydride copolymer (weight average molecular weight is 72000) in the form of white powder. The yield is 94%, and the maleic anhydride in the copolymer is The mass percentage of monomer units is 44%.

[0149] With 20 parts of this styrene-maleic anhydride copolymer, 5 parts of 37% ammoniacal liquor, 75 parts of water were stirred at room temperature for 4 hours, obtained the styrene-maleamic acid copolymer viscous liquid (copolymer) of mass concentration 20%. The mole percent of the maleic anhydride monomer units that have been ammonolyzed in the mixture is 99%). Mix th...

Embodiment 2

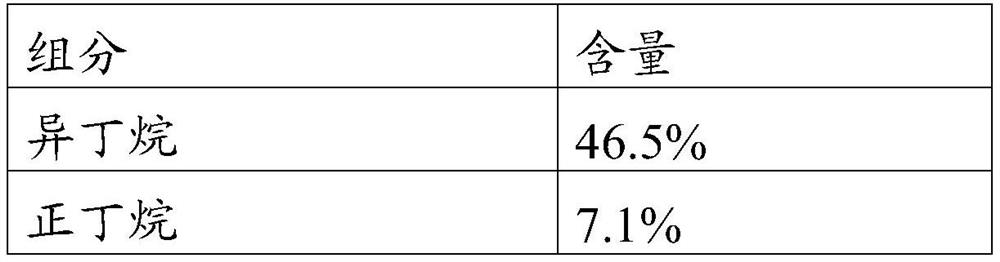

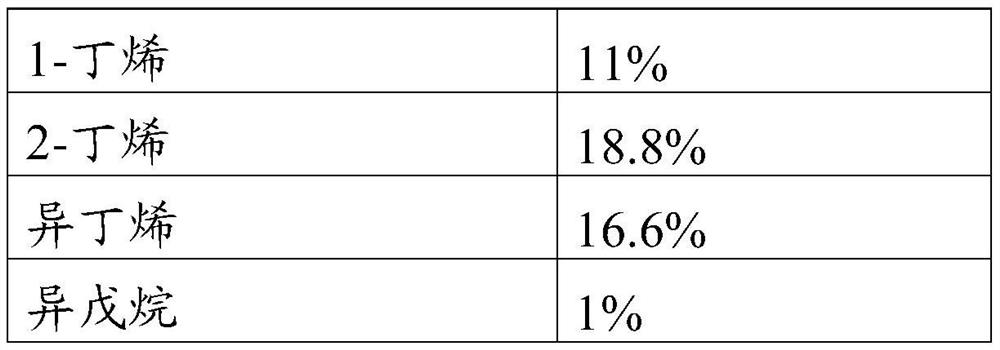

[0152] According to the mass parts, 100 parts of C 4 Distillate (composition shown in Table 1), 30 parts of maleic anhydride, 100 parts of isoamyl acetate and 2 parts of BPO were mixed and dissolved, and the system was reacted at 70° C. for 8 hours after passing nitrogen gas for 20 minutes. The product was centrifuged, washed three times with petroleum ether, and dried to obtain C in the form of a white powder. 4 -maleic anhydride copolymer (weight average molecular weight is 20000), the yield is 94%, and the mass percent of maleic anhydride monomer unit in the copolymer is 63%.

[0153] 10 copies of the C 4 -Maleic anhydride copolymer, 5 parts of 37% ammonia water, 85 parts of water were stirred at room temperature for 4 hours to obtain 10% mass concentration of C 4 -Maleamic acid copolymer (99% by mole of aminolyzed maleic anhydride monomer units in the copolymer) viscous liquid. The viscous liquid is uniformly mixed with poplar wood shavings (water content 5%, 5-10 mesh)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap