Simulation test equipment and method for super-load anchor pile cross beam counter-force device

A technology of reaction force device and simulation test, which is applied in the test of basic structure, construction, and basic structure engineering, etc., can solve the problems of inoperability and uneconomical

Pending Publication Date: 2021-05-28

SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But these two methods are nei

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

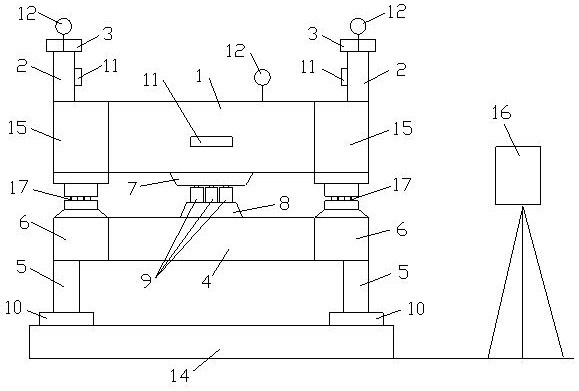

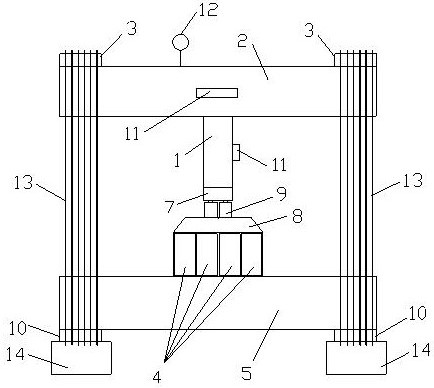

The invention discloses simulation test equipment and method for a super-load anchor pile cross beam counter-force device. In the equipment, the middle parts of two secondary beams are arranged on the top faces of the two ends of a main beam, and anchor pile caps are arranged on the top faces of the two ends of the secondary beams; two secondary pressure-bearing counter-force box girders are arranged on a test platform, and counter-force anchor pile caps are arranged on the bottom faces of the two ends of the secondary pressure-bearing counter-force box girders; four main pressure-bearing counter-force box girders are arranged side by side, and the two ends of the four main pressure-bearing counter-force box girders are arranged on the top faces of the middles of the two secondary pressure-bearing counter-force box girders; four-hole box girders are arranged at the two ends of the four main pressure-bearing counter-force box girders in a sleeving mode; an upper steel box cushion and a lower steel box cushion are arranged on the bottom face of the middle of the main beam and the top faces of the middles of the four main pressure-bearing counter-force box beams; six sets of jacks are arranged between the upper steel box cushion and the lower steel box cushion; a plurality of first twisted steel bars are welded between the anchor pile caps and the counter-force anchor pile caps; and a displacement sensor and a dial indicator are arranged on the main beam and the two secondary beams and used for detecting rigidity and deformation. According to the method, the main beam and the four main pressure-bearing counter-force box beams are subjected to graded loading and unloading through six sets of jacks, and whether the main beam and the secondary beams meet the requirement of the maximum load or not is judged.

Description

technical field [0001] The invention relates to the technical field of construction engineering, in particular to a simulation test equipment and method for super-large-load anchor pile beam reaction devices. Background technique [0002] The static load test of pile foundation is the most primitive and basic method to determine the bearing capacity of single pile, and it is also the most reliable method. The single pile static load test is a test method close to the actual working conditions of vertical compression. The load acts on the top of the pile to cause displacement (settlement) of the top of the pile, and the load-settlement (P-S) curve of a single test pile can be obtained. Sedimentation-time logarithmic (S-lgt) curves can be obtained, as well as other curves required for analysis. [0003] Generally, single pile static load test equipment is composed of loading device and load and deformation observation device. The loading device is composed of main beam, seco...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02D33/00

CPCE02D33/00

Inventor 孙启栋张西峰孙延生刘云朋郝世龙孙鑫钱锟余士伟董建纲

Owner SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com