A method for inspecting particle size distribution of pulverized coal

A coal powder particle size and particle size distribution technology, applied in particle size analysis, particle and sedimentation analysis, material analysis, etc., can solve problems such as difficulties, increased cost of coal powder production, and complex process control of grinding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The method for inspecting the particle size distribution of pulverized coal in a coal mill in a factory includes the following steps:

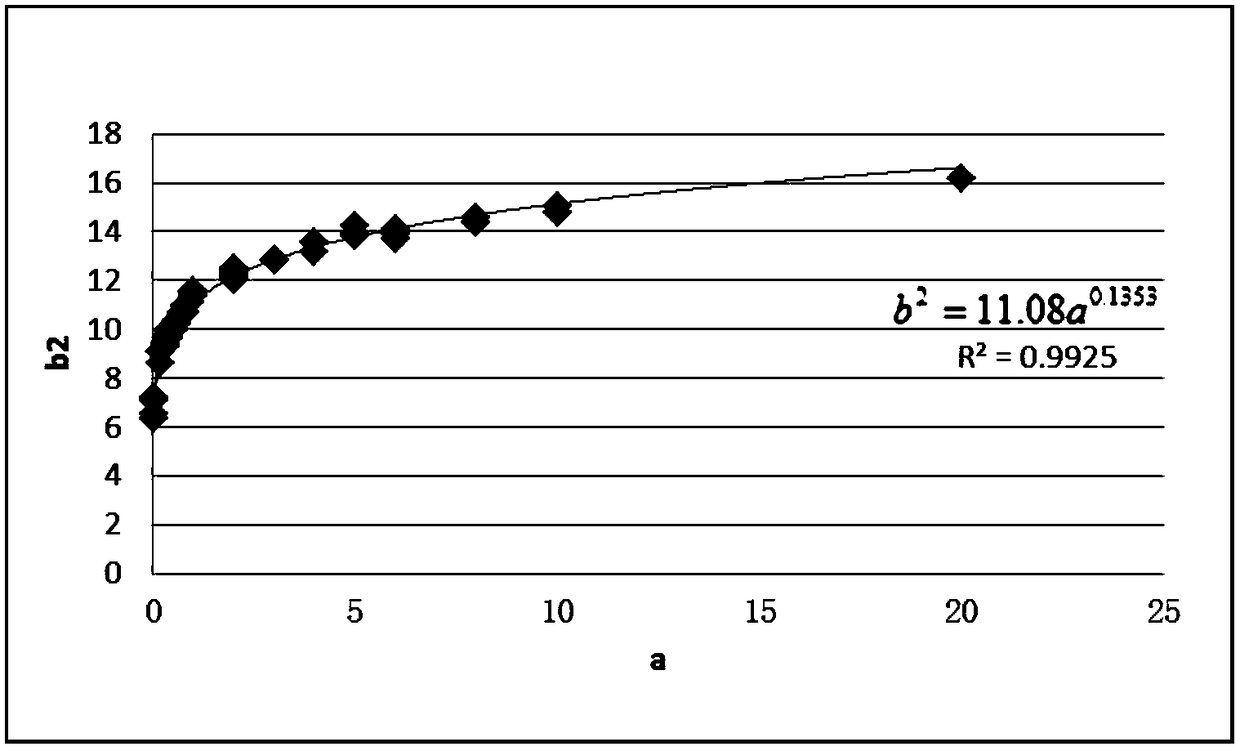

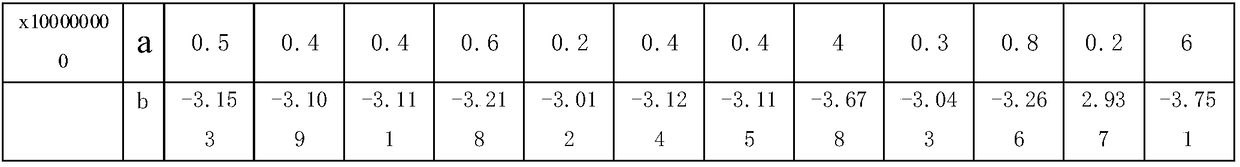

[0018] S1: The particle size distribution of coal powder is represented by a power function, which represents the relationship between the particle size of pulverized coal at the outlet of the coal mill and its percentage content. The power function of the particle size distribution is expressed as follows;

[0019] y=ax b (1)

[0020] In the formula: a is the proportional constant of the particle size distribution; b is the power of the particle size distribution; x is the particle size diameter in μm; Y is the mass fraction;

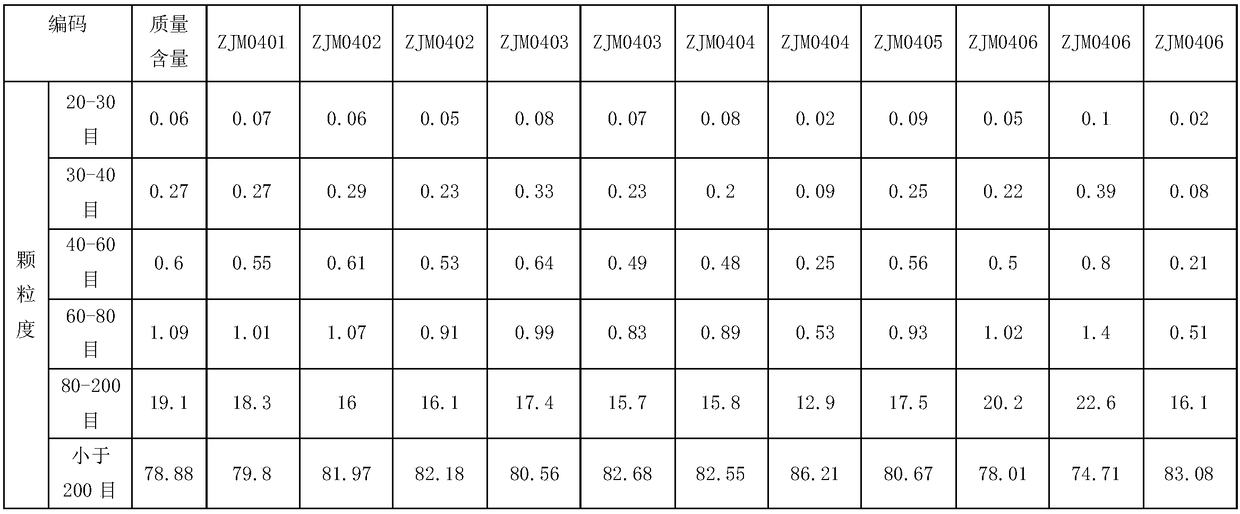

[0021] S2: Sieve the coal powder from the coal mill according to the industrial analysis of particle size, and convert the mesh number into particle size μm, and measure the percentage content of different particle sizes, as shown in Table 1 below:

[0022]

[0023] S3: the above-mentioned measured percent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com