Patents

Literature

35results about How to "Test stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

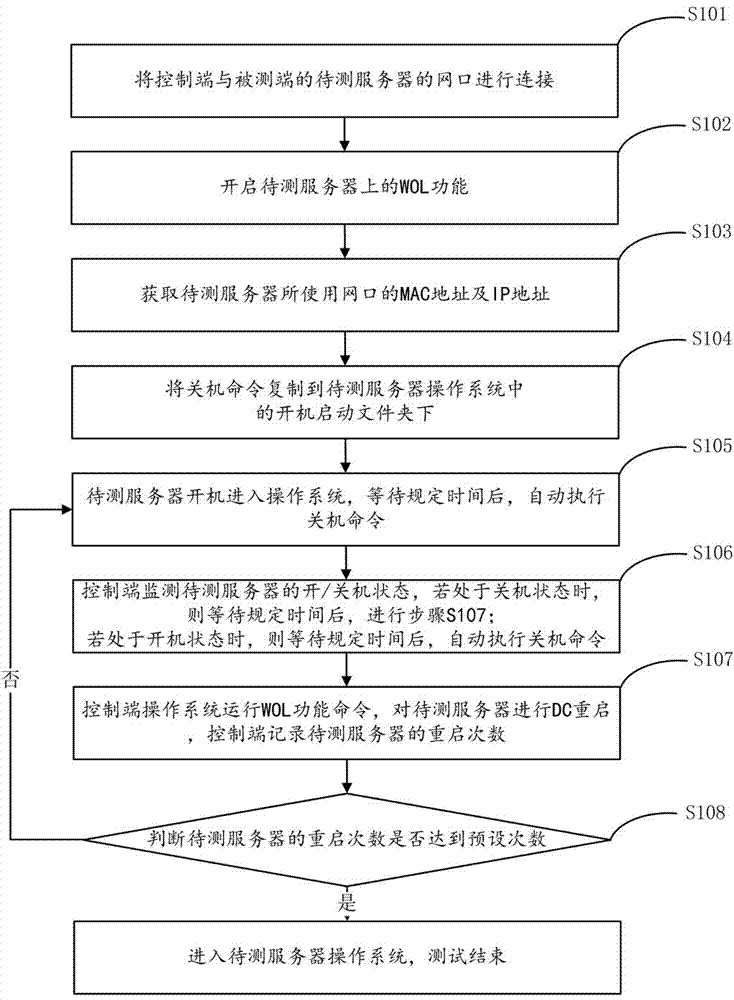

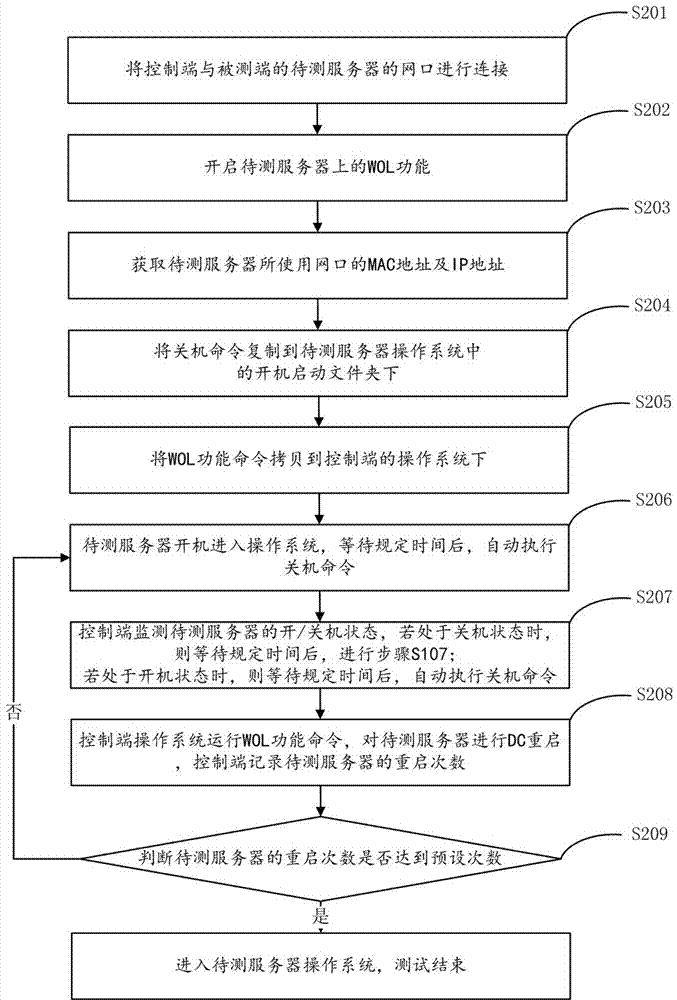

Test method for performing DC reboot on server based on WOL function

InactiveCN106933710AEasy to operateReduce test costDetecting faulty computer hardwareIp addressSetting time

The invention discloses a test method for performing DC reboot on a server based on a WOL function. The method comprises the steps that a control terminal is connected with an Internet access of the server to be tested of a tested terminal; the WOL function of the server to be tested is started; an MAC address and an IP address of the Internet access applied to the server to be tested are acquired; a shutdown command is copied to a startup folder in an operating system of the server to be tested; the server to be tested is started up to enter the operating system, and the shutdown command is automatically executed after set time is up; the control terminal monitors the power-on / off state of the server to be tested; an operating system of the control terminal runs a WOL function command, DC reboot is performed on the server to be tested, and the control terminal records the number of times of reboot of the server to be tested; and whether the number of times of reboot of the server to be tested reaches a preset number of times or not is judged. According to the method, the Internet access wake-up function is utilized to perform cyclic reboot on the server in a DC power-off state, and the method is an automatic monitoring method with high practicability and a wide application range.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

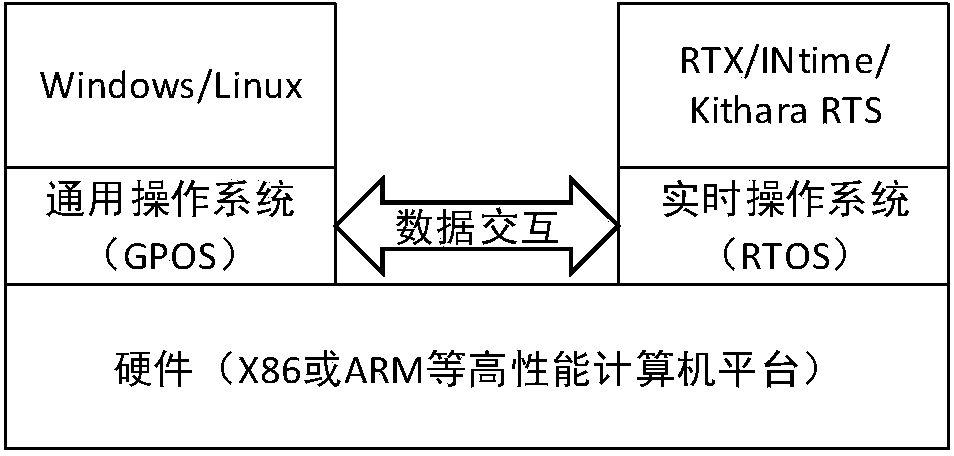

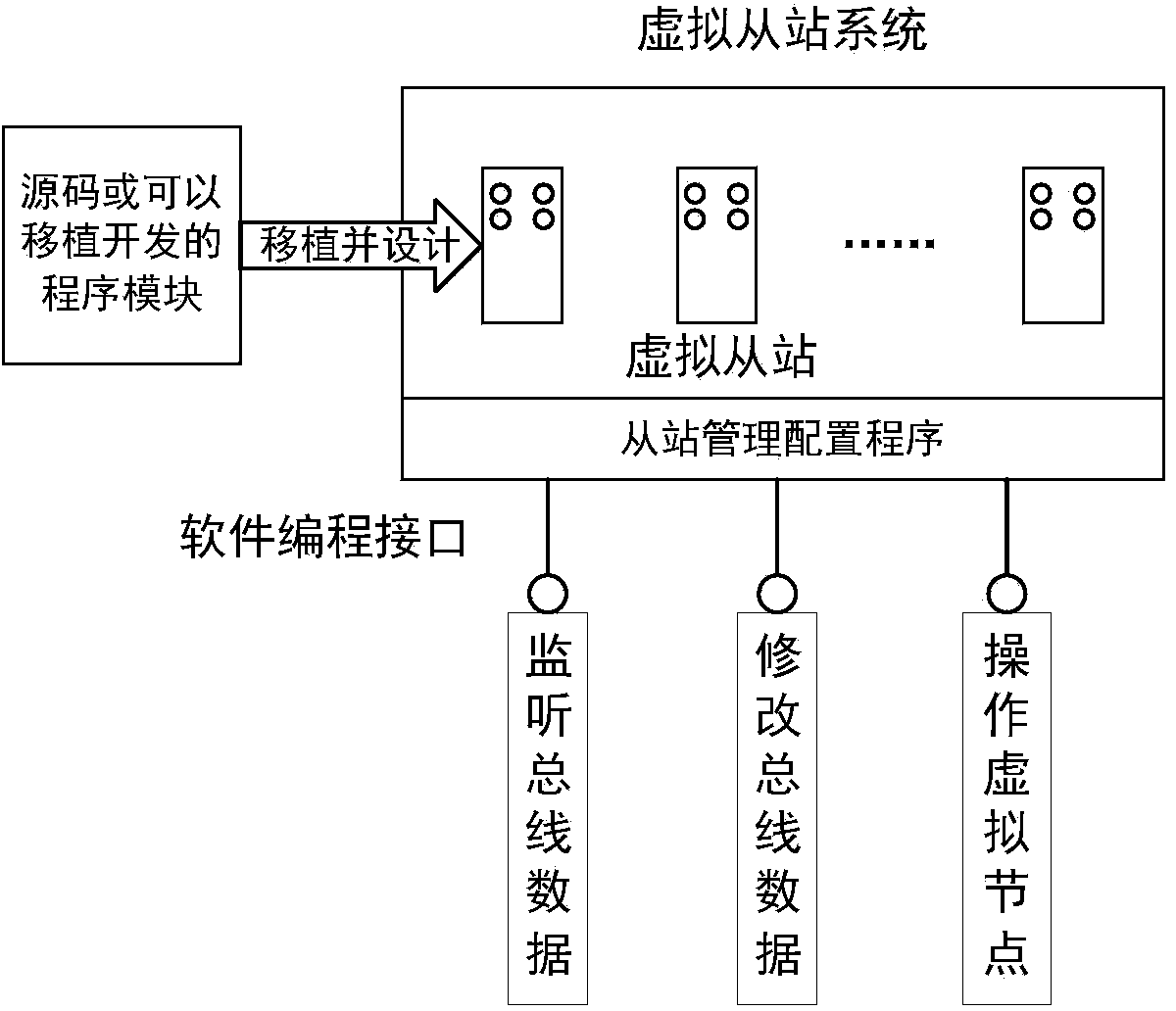

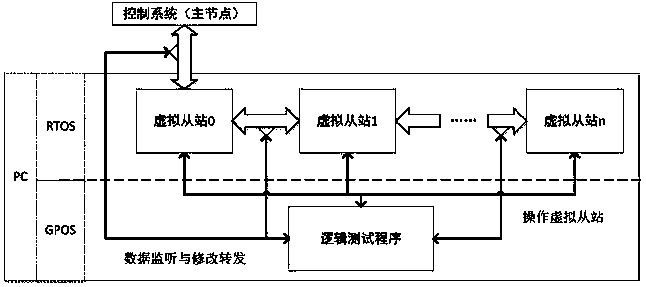

Semi-virtual functional test device and method for control system

InactiveCN103425055ALow costR&D phase of rapid developmentSimulator controlOperational systemTest fixture

The invention discloses a semi-virtual functional test device and method for a control system. According to the method, in detail, a plurality of virtual slave station nodes are established in a real-time operation system of a computer to replace real slave station nodes and connected with a master station of the system to be tested through bus communication interfaces. Meanwhile, in a general operation system operating on the computer in parallel, and a software programming interface development procedure provided by virtual slave stations is used for achieving monitoring and a performance analysis of bus data and simulating functions of user input or device input, so that full-automatic testing is performed on the control system. Needed hardware is only one computer with the specific communication interface, and the general operation system and the real-time operation system operate on the computer in parallel. The semi-virtual functional test device and method have the advantages of being low in cost, high in testing efficiency and the like, can be suitable for developing, commissioning, functional testing and other testing occasions of the control system, and have good practical value and application prospects.

Owner:SHANDONG UNIV

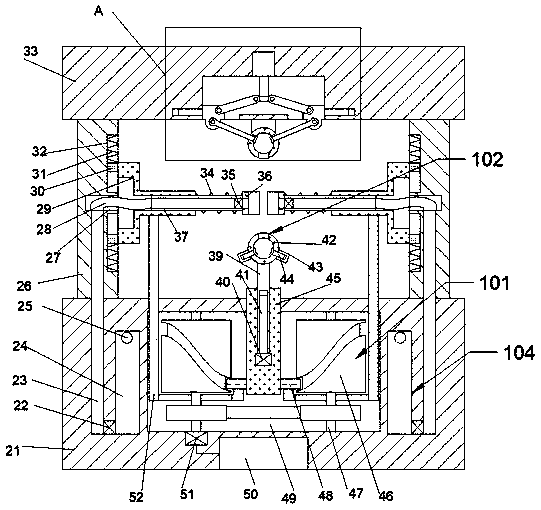

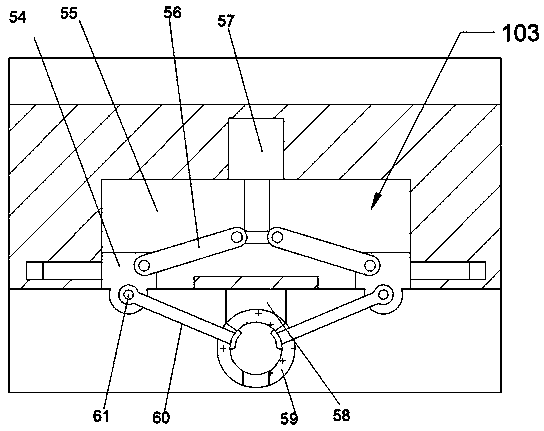

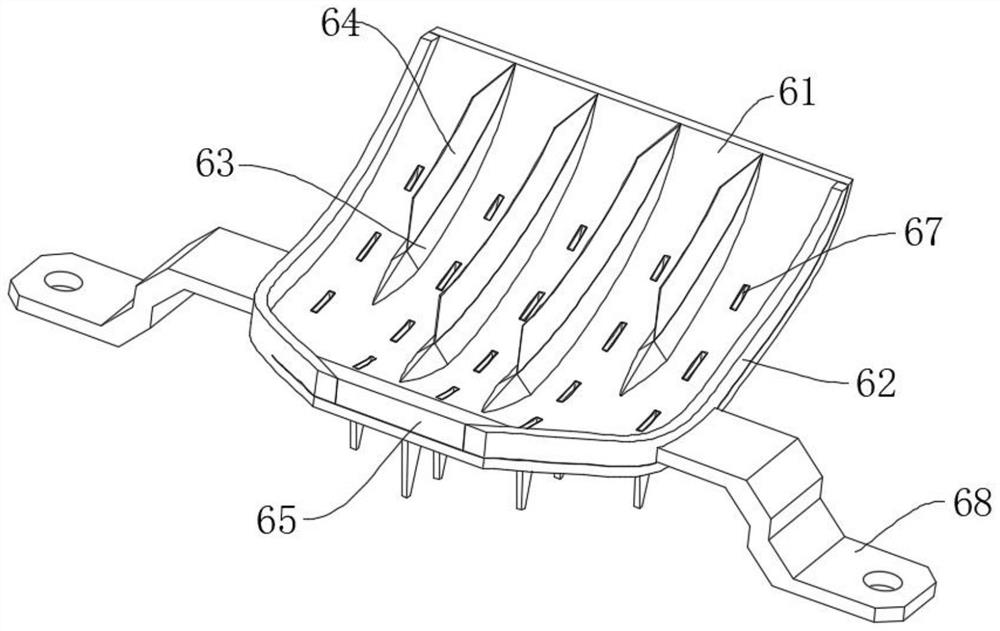

Testing device for automobile shock absorber

InactiveCN111141535ATest stabilityImprove inspection efficiencyDetection of fluid at leakage pointVehicle suspension/damping testingEngineeringMachine

The invention discloses a testing device for an automobile shock absorber, which comprises a machine body. Supporting columns are fixedly arranged on the top face of the machine body in a bilateral symmetry mode. A top cover is fixedly arranged on the top faces of the two connecting pipelines; a driving space is formed in the machine body. A bottom fixing block capable of moving up and down is arranged, therefore, the stability of the shock absorber can be tested; meanwhile, whether the shock absorber leaks oil or not can be tested through the test ointment stored in the shock absorber; compared with a traditional detection device, the device disclosed in the invention can detect the two properties of the shock absorber at the same time, so that the detection efficiency can be effectivelyimproved, meanwhile, the device can be suitable for shock absorbers of different specifications, and therefore the practicability of the device can be effectively improved.

Owner:福州市闽侯县浩恩汽车用品有限公司

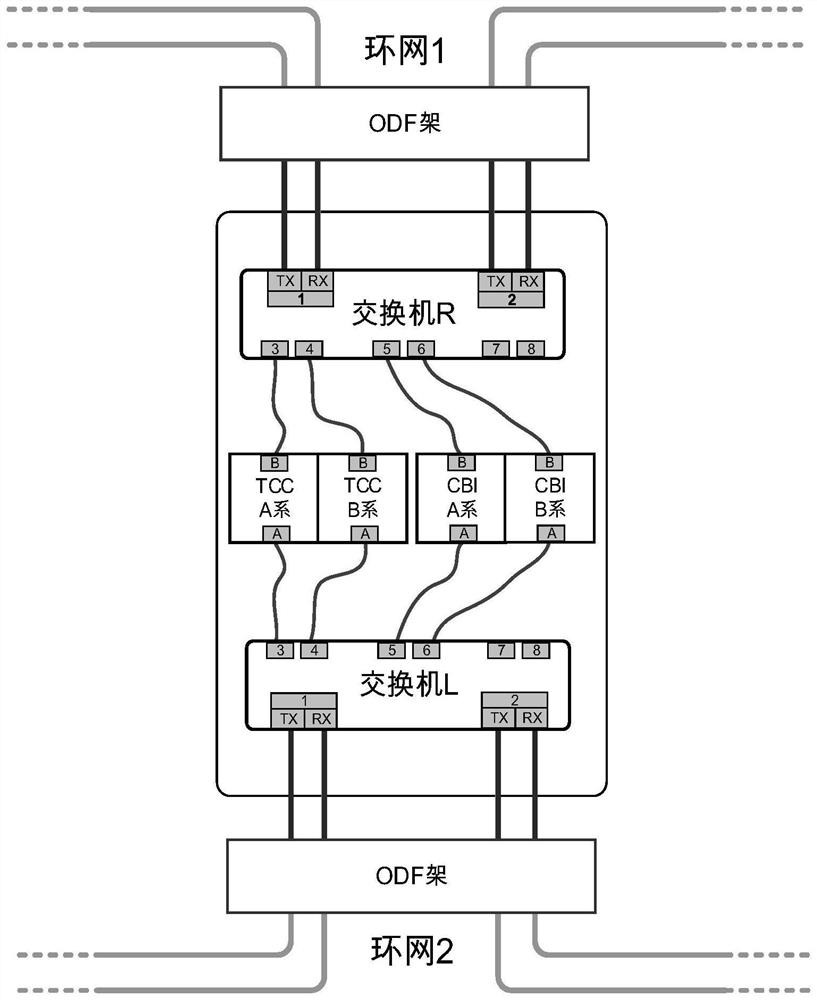

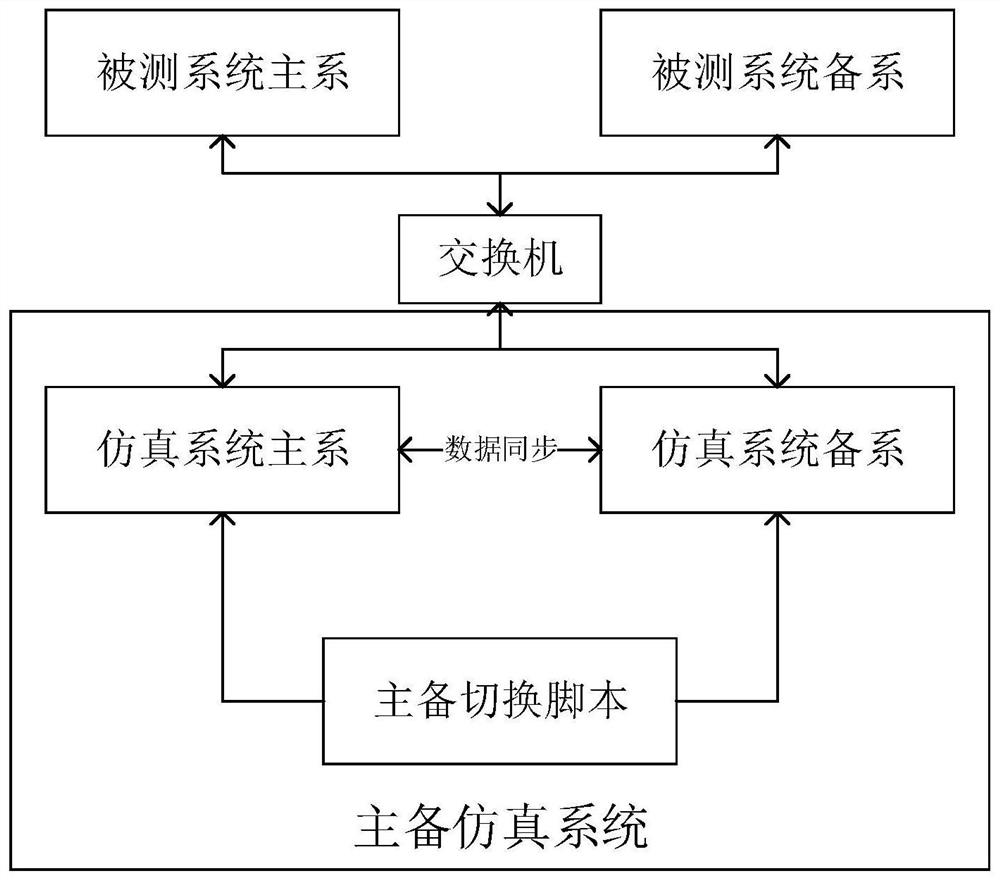

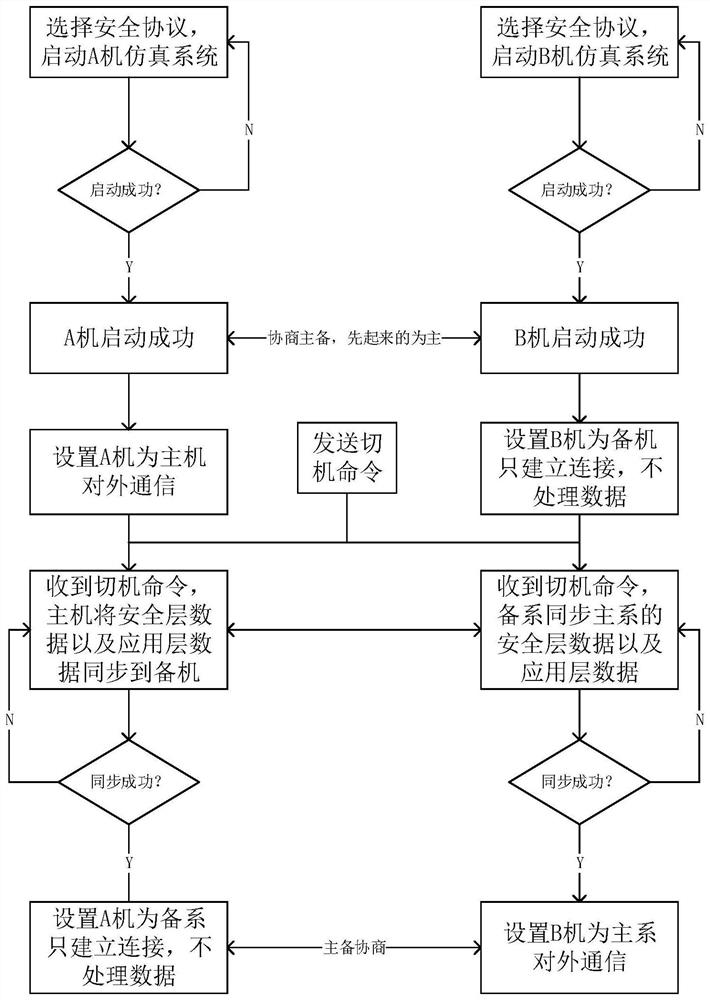

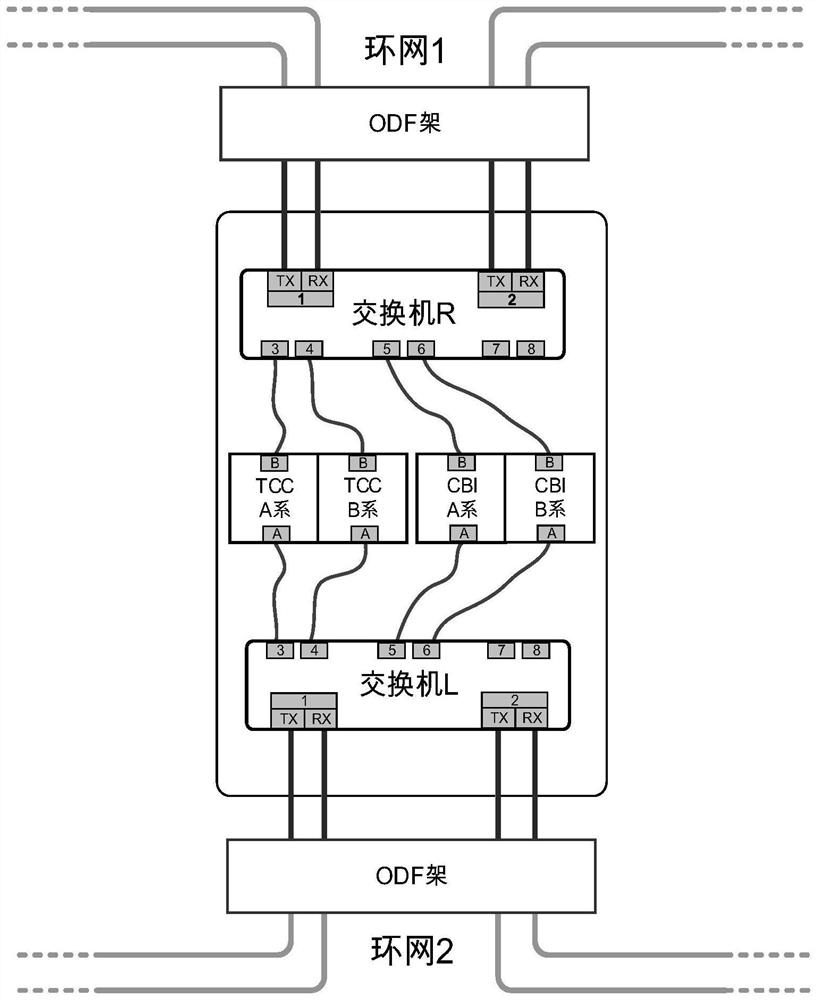

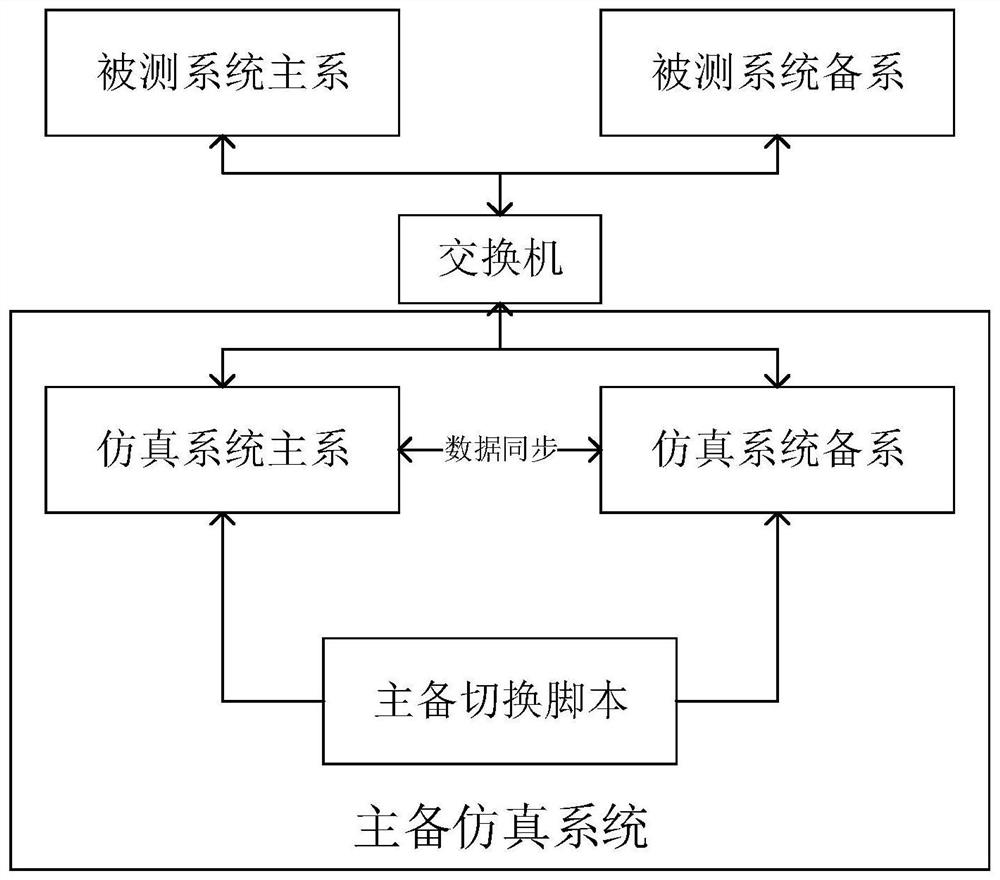

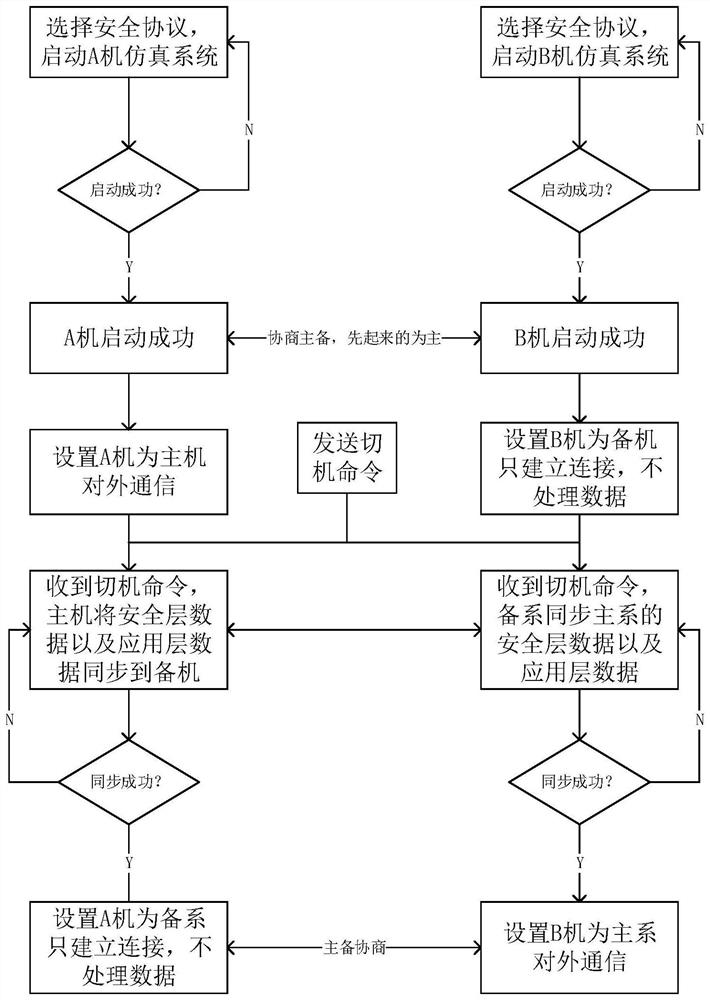

Simulation system main/standby switching method based on railway safety communication protocol

ActiveCN112615728AResolve interruptionImprove test stabilityRailway traffic control systemsData switching networksData synchronizationSecure communication

The invention relates to a simulation system main / standby switching method based on a railway safety communication protocol, and the method comprises the following steps: S1, initializing a system, and selecting a simulation protocol simulated by an external simulation system; S2, compiling an automatic switching or manual switching script, and sending a switching command; S3, before executing the switching command, performing data synchronization on the main system and the standby system of the simulation system; S4, after the main system and the standby system of the simulation system receive the generator tripping instruction, determining that the main system and the standby system are synchronized at the same time, and converting roles of the main system and the standby system into the standby system or the main system; and S5, recording network information in the switching process. Compared with the prior art, the method has the advantages of solving the problems of secure communication interruption and application data interruption caused by dual-computer switching of the secure communication protocol and the like.

Owner:CASCO SIGNAL

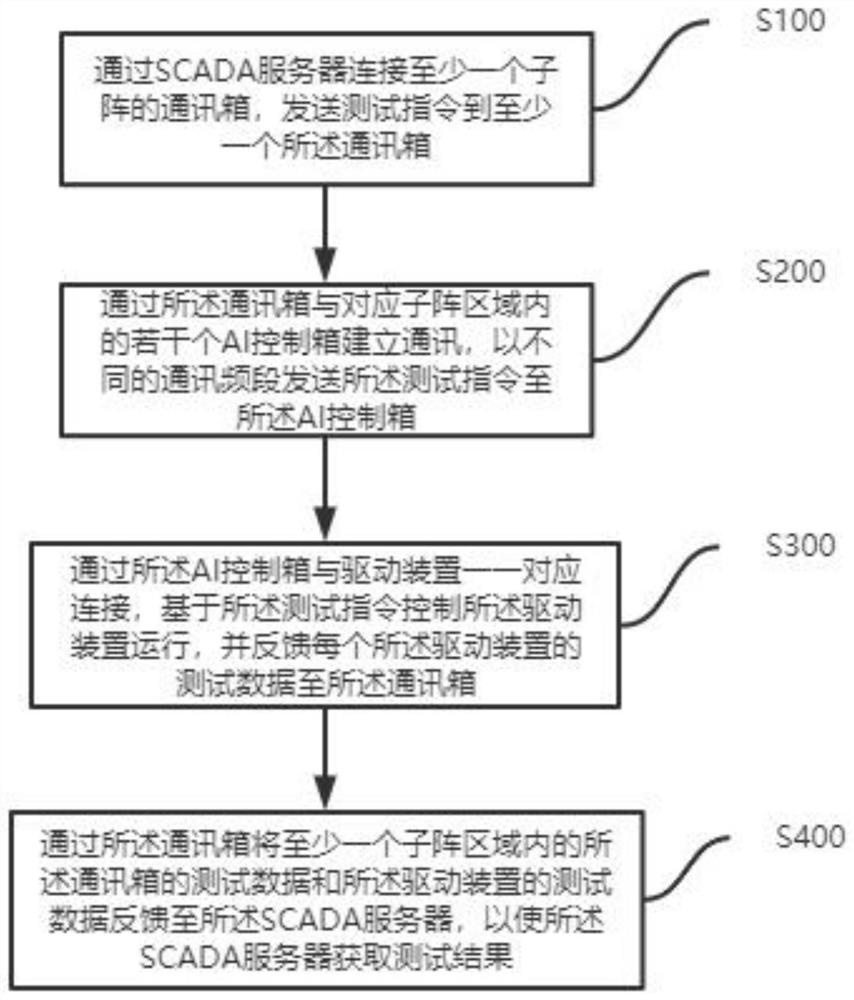

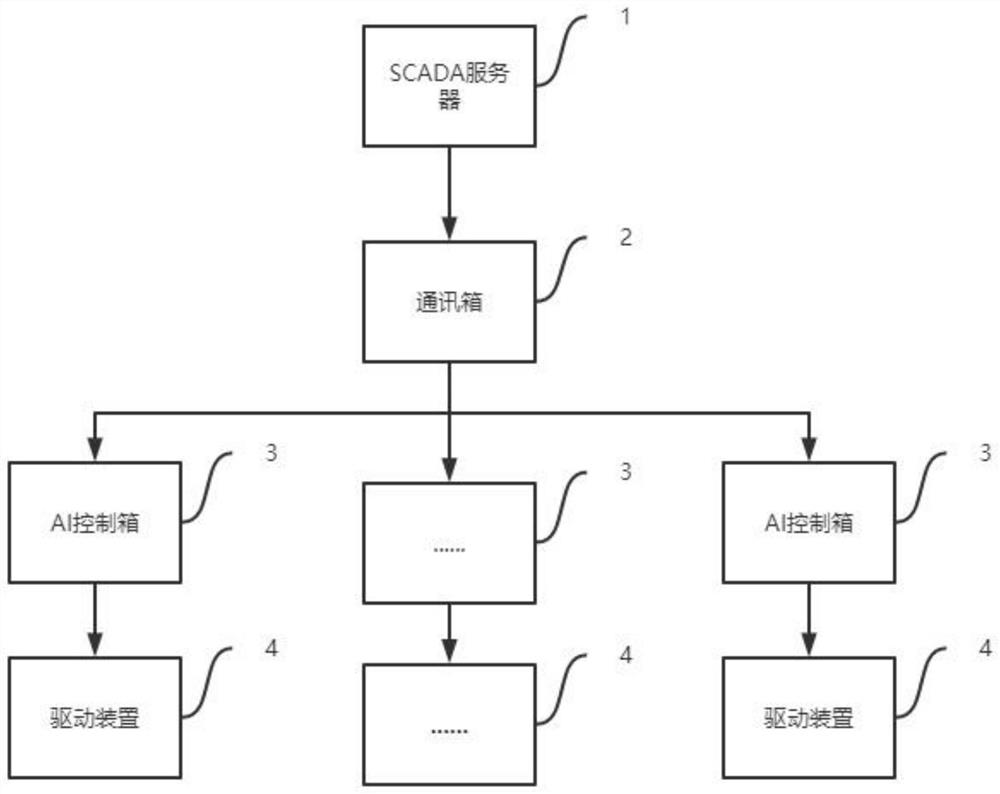

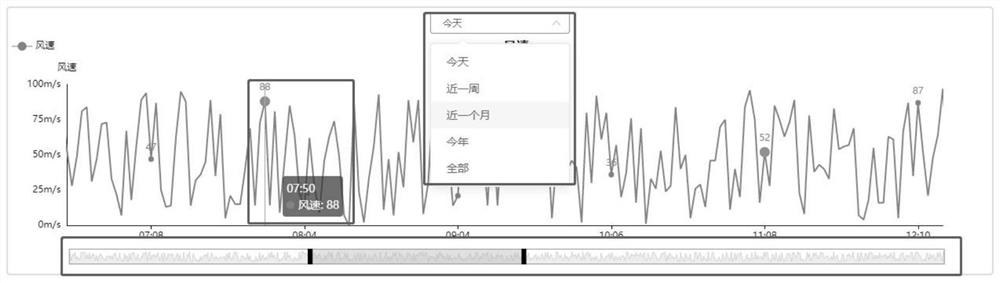

Multifunctional integration test method and system for photovoltaic support array

PendingCN113078731AComprehensive verification of operational reliabilityStatus acquisitionPhotovoltaic monitoringCircuit arrangementsSCADAControl system

The invention relates to the technical field of photovoltaic trackers, and provides a multifunctional integration test method and system for a photovoltaic support array, and the method comprises the steps: connecting a communication box of at least one sub-array through an SCADA server, and transmitting a test instruction to at least one communication box; establishing communication with a plurality of AI control boxes in the corresponding sub-array areas through the communication boxes, and sending test instructions to the AI control boxes in different communication frequency bands; connecting the AI control boxes with driving devices in a one-to-one correspondence mode, controlling the driving devices to operate based on test instructions, and feeding back test data of each driving device to a communication box; and feeding back the test data of the communication box in the at least one sub-array area and the test data of the driving device to an SCADA server through the communication box, so that the SCADA server obtains a test result. According to the invention, the SCADA server sends out a test instruction, receives test data fed back by the communication box, and carries out all-around verification on the operation reliability of the photovoltaic power station array control system.

Owner:ARCTECH SOLAR HLDG CO LTD

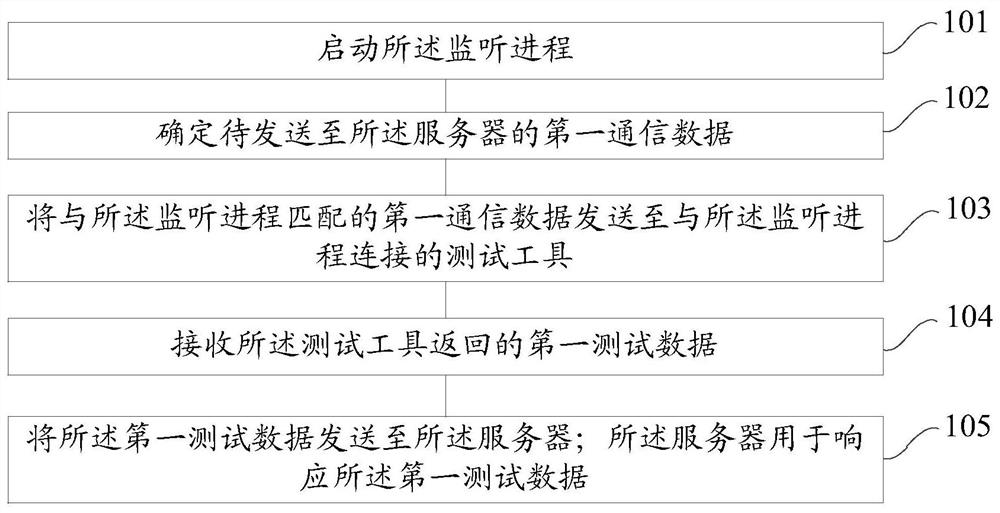

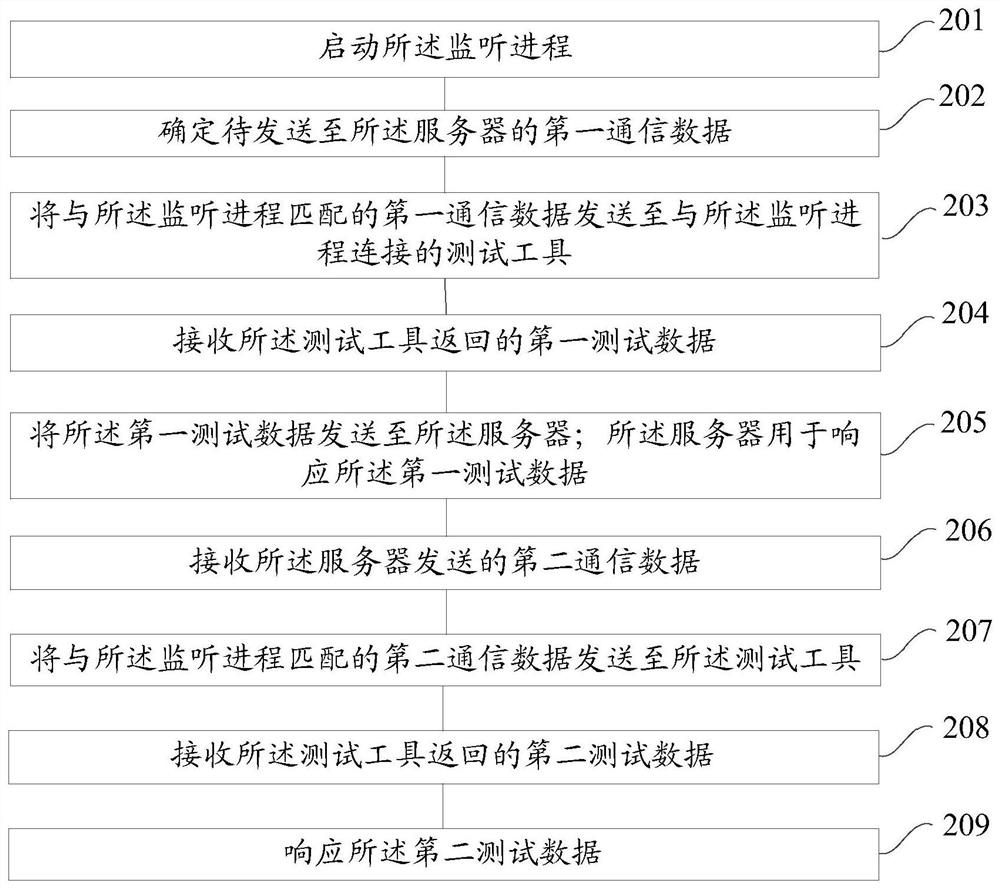

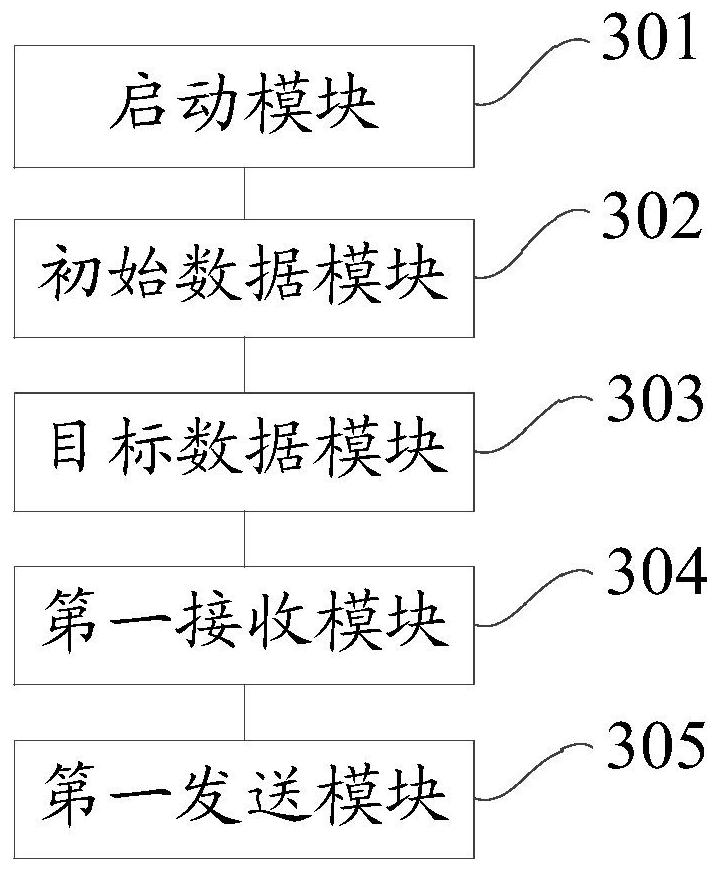

A test method, device, electronic equipment and storage medium

The embodiment of the present invention provides a test method, device, electronic equipment and storage medium, the method is applied to a client, the client is provided with a monitoring process, and the client is connected to a preset server; the method Including: starting the monitoring process; determining the first communication data to be sent to the server; sending the first communication data matching the monitoring process to a test tool connected to the monitoring process; receiving the testing tool return the first test data; send the first test data to the server; the server is used to respond to the first test data. The embodiment of the present invention can test the function and stability of the server, effectively prevent the hidden danger of communication data being leaked and tampered with due to the leakage of the test tool, and increase the stability of the software system composed of the client and the server and security.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

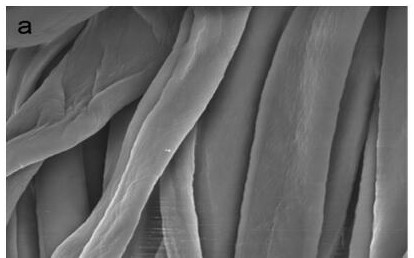

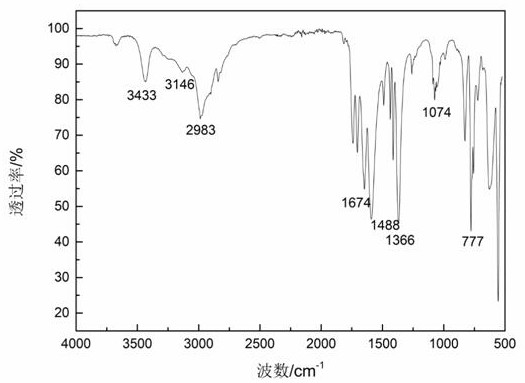

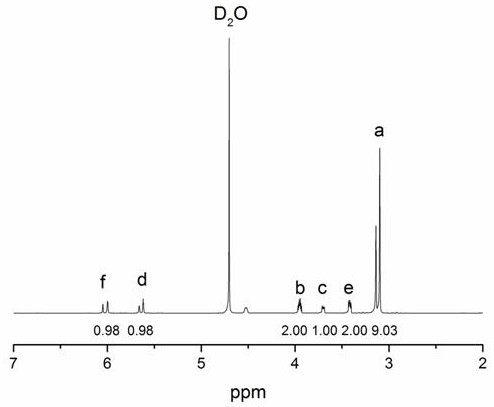

Preparation method and application of cationic modifier TCTAC

ActiveCN113373691ATest mechanical propertiesTest stabilityBiochemical fibre treatmentWrinkle resistant fibresCyanuric chlorideAnti bacterial

The invention discloses a preparation method and application of a cationic modifier TCTAC, and relates to the technical field of anti-wrinkle and antibacterial finishing of cotton fabrics. The preparation method comprises the following steps of dissolving 2,3-epoxy hydroxypropyl trimethyl ammonium chloride in deionized water, dropwise adding ammonia water, heating and stirring for a reaction, and dissolving in deionized water to form a 1-amino-3-hydroxypropyl trimethyl ammonium chloride aqueous solution; and dissolving cyanuric chloride in acetone, dropwise adding the 1-amino-3-hydroxypropyl trimethyl ammonium chloride aqueous solution, adjusting the pH value to 6-7 by using a sodium carbonate aqueous solution, stirring for a reaction until the reaction is finished, performing salting-out purification and drying to obtain the cationic modifier TCTAC. According to the method, the synthesis period is short, the yield is high, the novel cationic modifier is synthesized, the cationic modifier can be used for carrying out anti-wrinkle / antibacterial dual-function treatment on a cotton fabric, and relative slippage among fibers can be effectively inhibited, so that the wrinkle recovery capability is improved, and the cotton fabric with excellent dry and wet wrinkle resistance can be obtained.

Owner:JIANGSU LIANFA TEXTILE +1

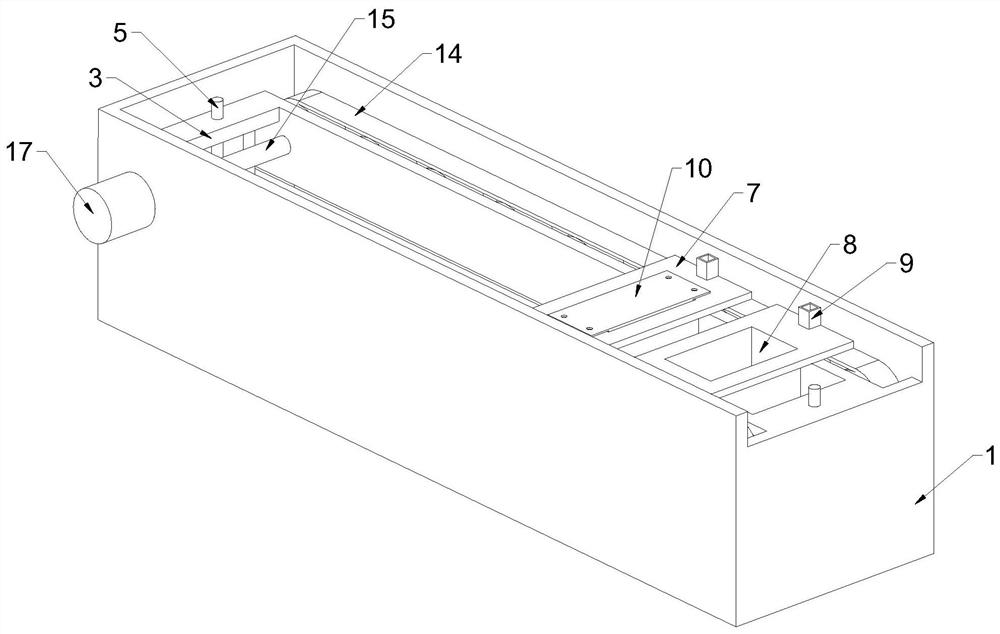

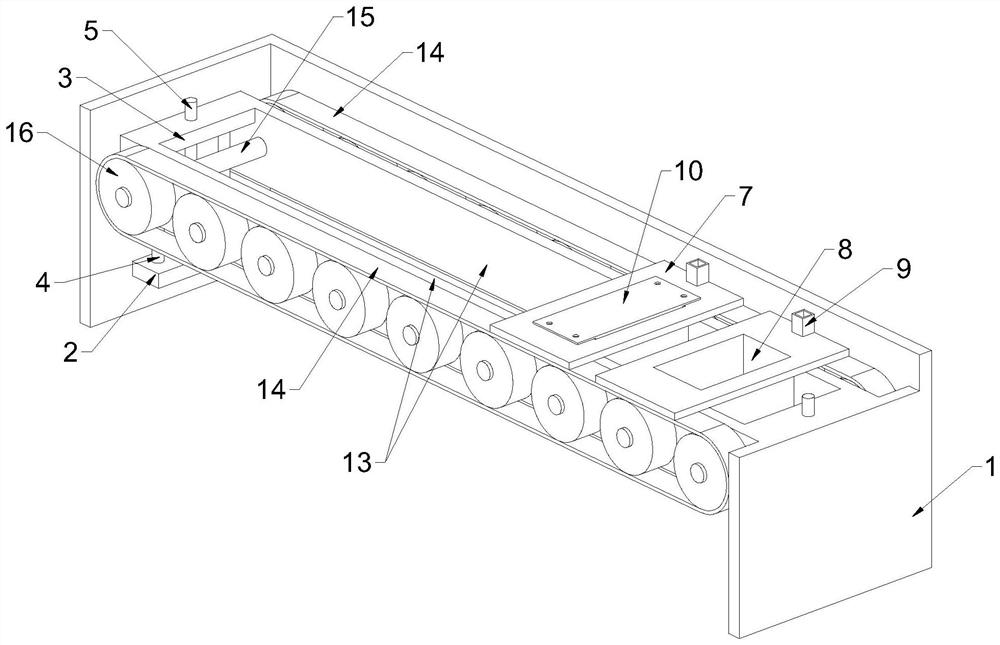

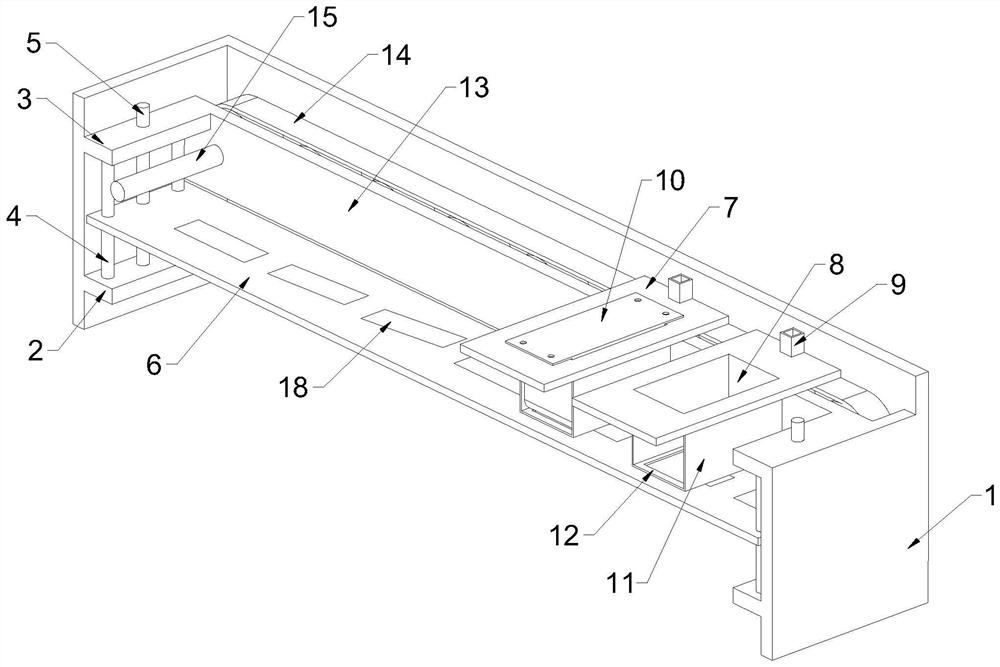

A magnetic head testing tool suitable for various types of magnetic heads

ActiveCN112542182BTest stabilityImprove versatilityFunctional testing of recording headsSlide plateConveyor belt

The invention relates to the technical field of magnetic head detection, and provides a magnetic head testing tool suitable for various types of magnetic heads. Including the frame, the left and right ends of the frame are provided with an upper support plate and a lower support plate, the rotating screw makes the magnetic strip plate slide up and down on the slide bar, multiple sets of magnetic strips are attached to the upper end of the magnetic strip plate, and a vertical plate is arranged inside the frame , There is a set of rollers that rotate between the vertical plate and the frame, and each set of rollers is connected with a conveyor belt. A slide plate is placed between the conveyor belts on the front and rear sides. There is a magnetic head slot in the middle of the slide plate. The magnetic head slot, frame and The back-shaped baffle forms a groove together, and the magnetic head is placed in the groove. There is a wiring bar on one side of the slide plate, which is connected to the magnetic head through the wiring discharge, and at the same time, the control of the read information of the magnetic head can be displayed through the wiring discharge connection. equipment. The invention is applicable to the performance test of different specifications and different types of magnetic heads at the same time, improves the universality of the magnetic head test tool, and can test the performance stability and performance limit of the magnetic head.

Owner:全南群英达电子有限公司

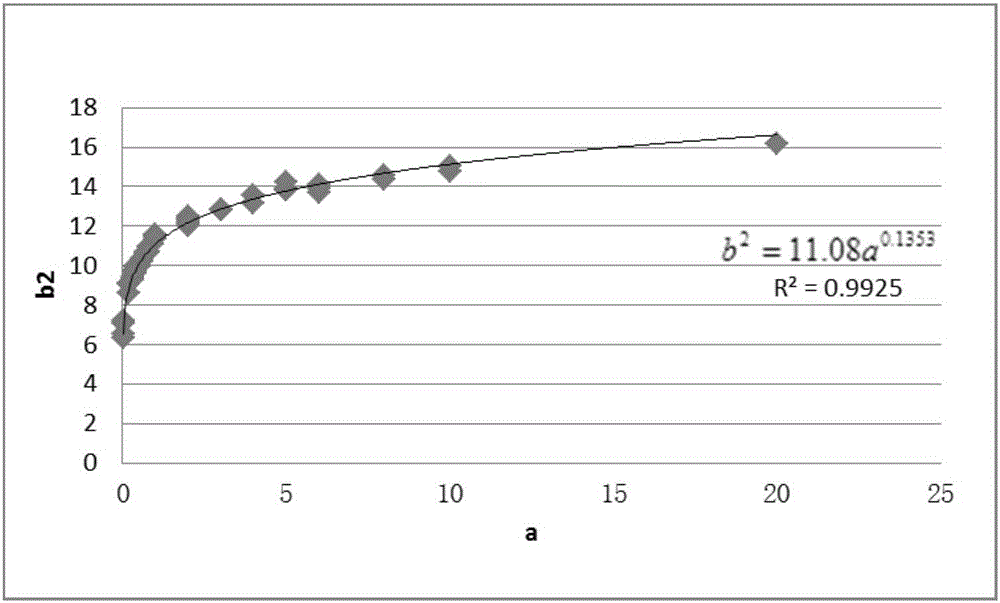

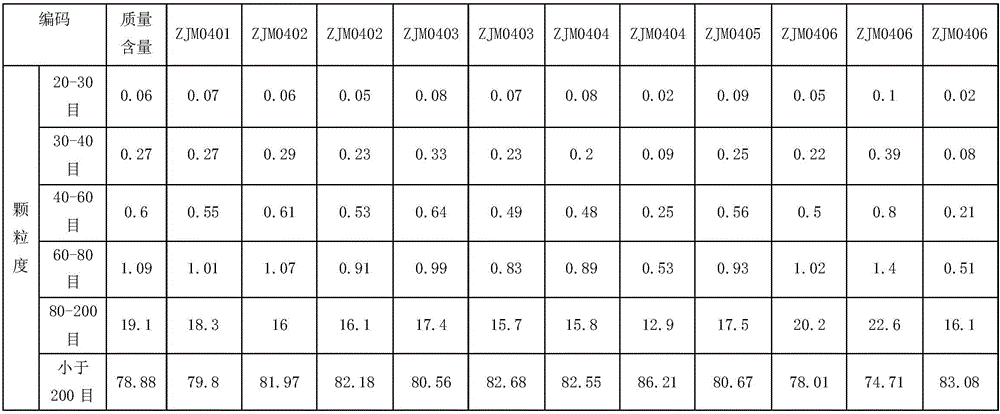

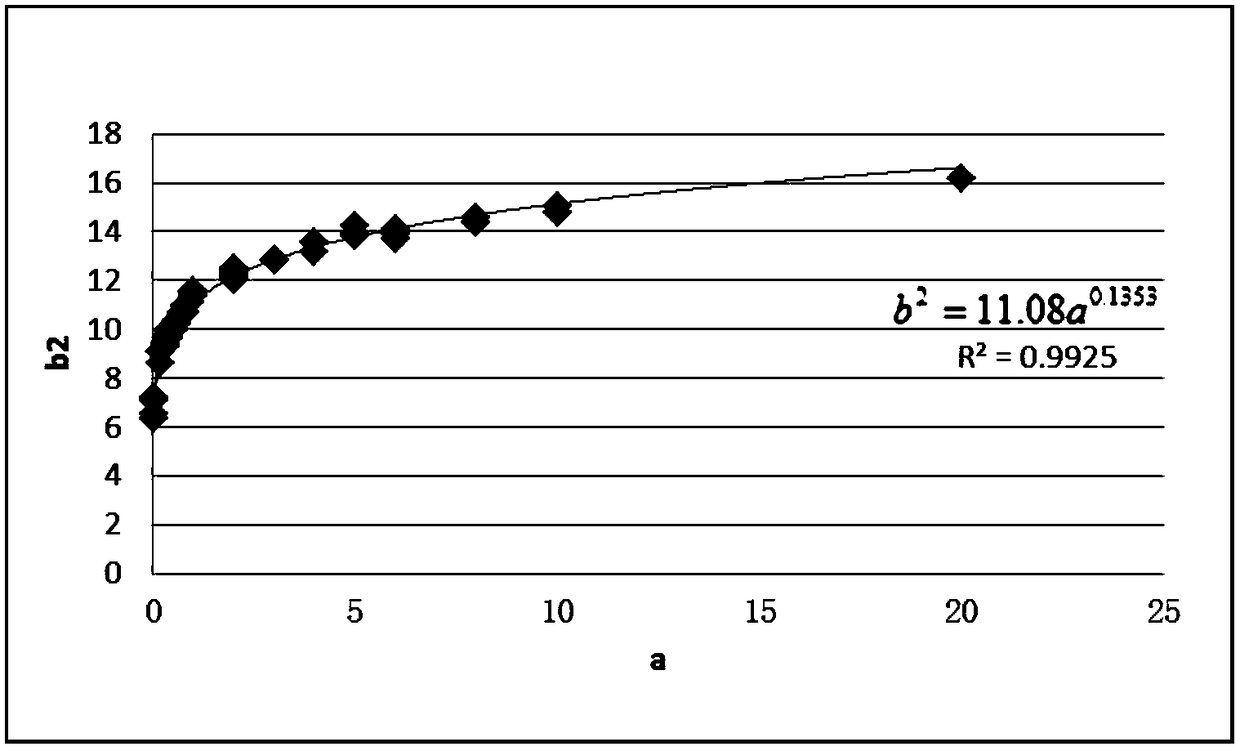

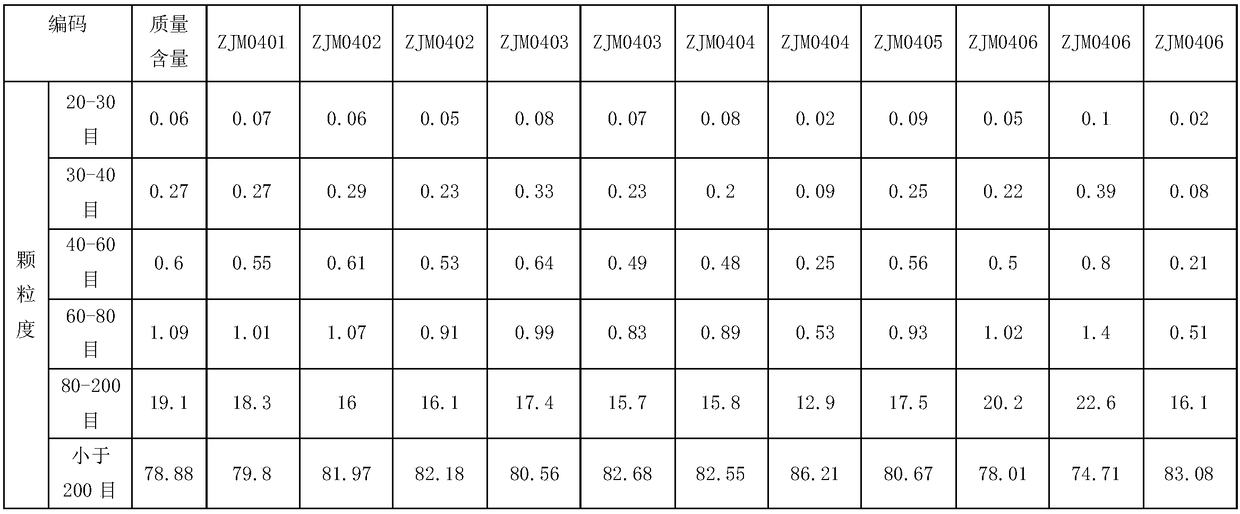

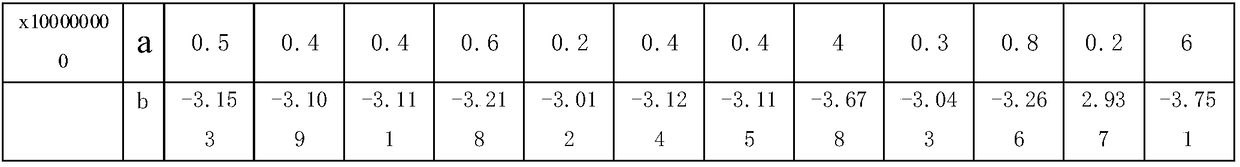

Method for inspecting pulverized coal particle size distribution

The invention discloses a method for inspecting the pulverized coal particle size distribution. According to the method, the pulverized coal particle size distribution is expressed by using a power function, pulverized coal which is pulverized by coal pulverizers is screened according to particle size industrial analysis, a mesh number is converted into particle diameter mu m, and the percent content of different particle diameters is measured; the measured percent content of the different particle diameters is introduced to an equation of the power function, so as to determine a and b, and then drawing is performed by using the particle diameter as an X axis and the mass fraction as a Y axis, so that whether the particle size of the pulverized coal which is pulverized by the coal pulverizers is stable can be determined according to the relationship between a and b. According to the method for inspecting the pulverized coal particle size distribution, a and b values in the corresponding equation of the particle size distribution are different for different coal pulverizers, but a certain function relationship exists, and whether the a and b values which are calculated according to products pulverized by the coal pulverizers conform to the function relationship is determined, so as to express the pulverized coal particle size and determine the stability of the pulverized coal which is pulverized by the coal pulverizers.

Owner:CHINA UNIV OF MINING & TECH YINCHUAN COLLEGE +1

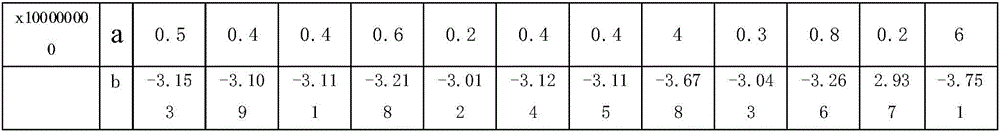

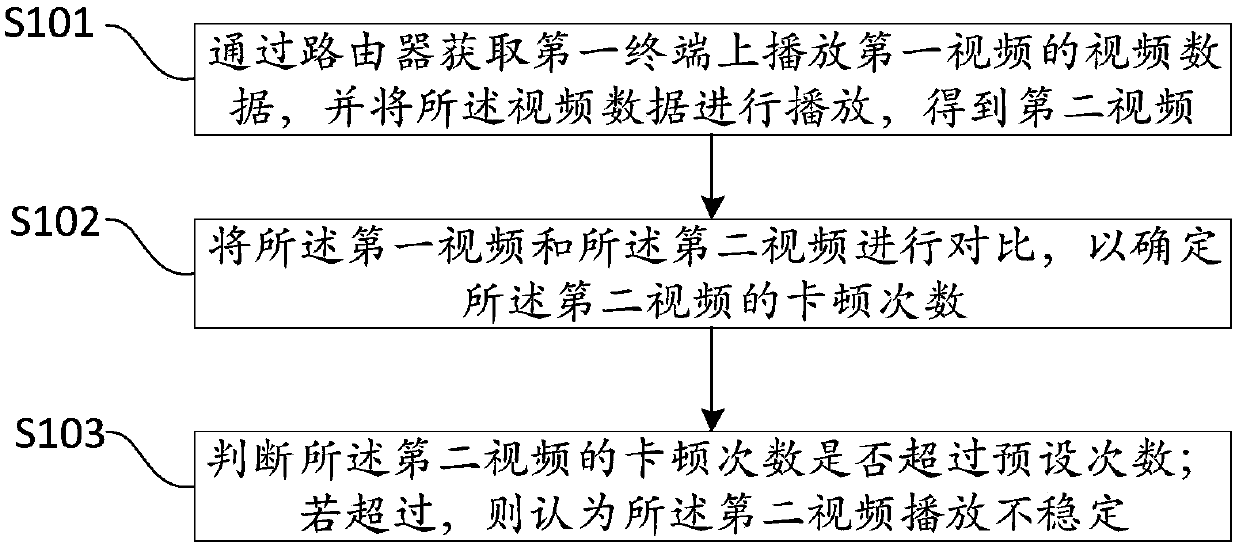

Test method and system for video stability

InactiveCN107734326AEasy to buildEasy to test and deployTelevision systemsSelective content distributionNetwork communicationComputer engineering

The invention discloses a method and system for testing video stability, and relates to the technical field of network communication. The method for testing video stability includes: acquiring video data of a first video played on a first terminal through a router, and downloading the video Playing the data to obtain a second video; comparing the first video with the second video to determine the number of freezes of the second video; judging whether the number of freezes of the second video exceeds a preset The number of times; if it exceeds, it is considered that the playback of the second video is unstable. The method provided by the invention is simple and convenient to test and deploy, and can automatically calculate the number of freezes during the playing process of the video, so as to judge the stability of the playing video.

Owner:台州市吉吉知识产权运营有限公司

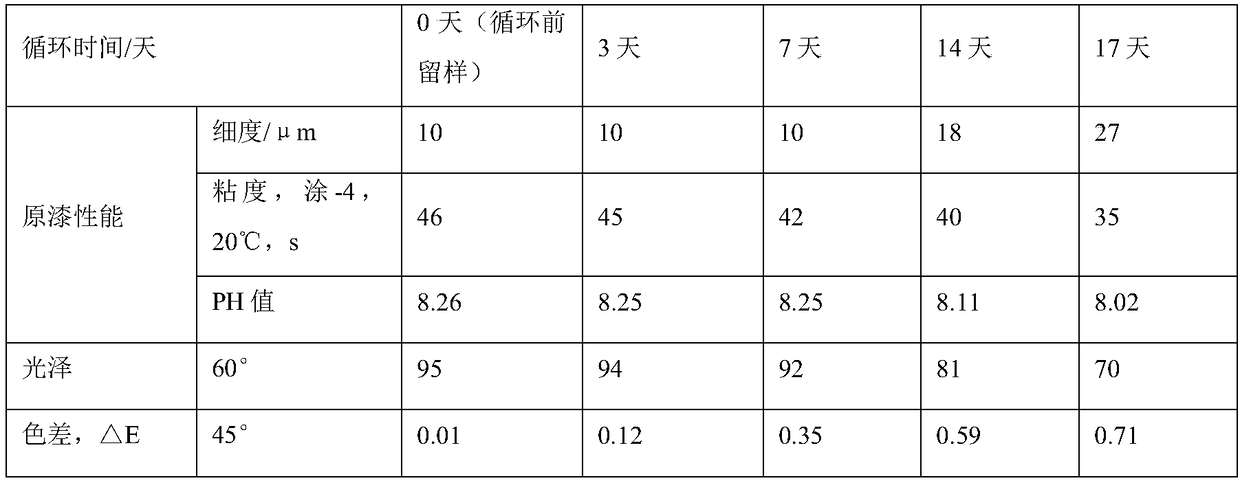

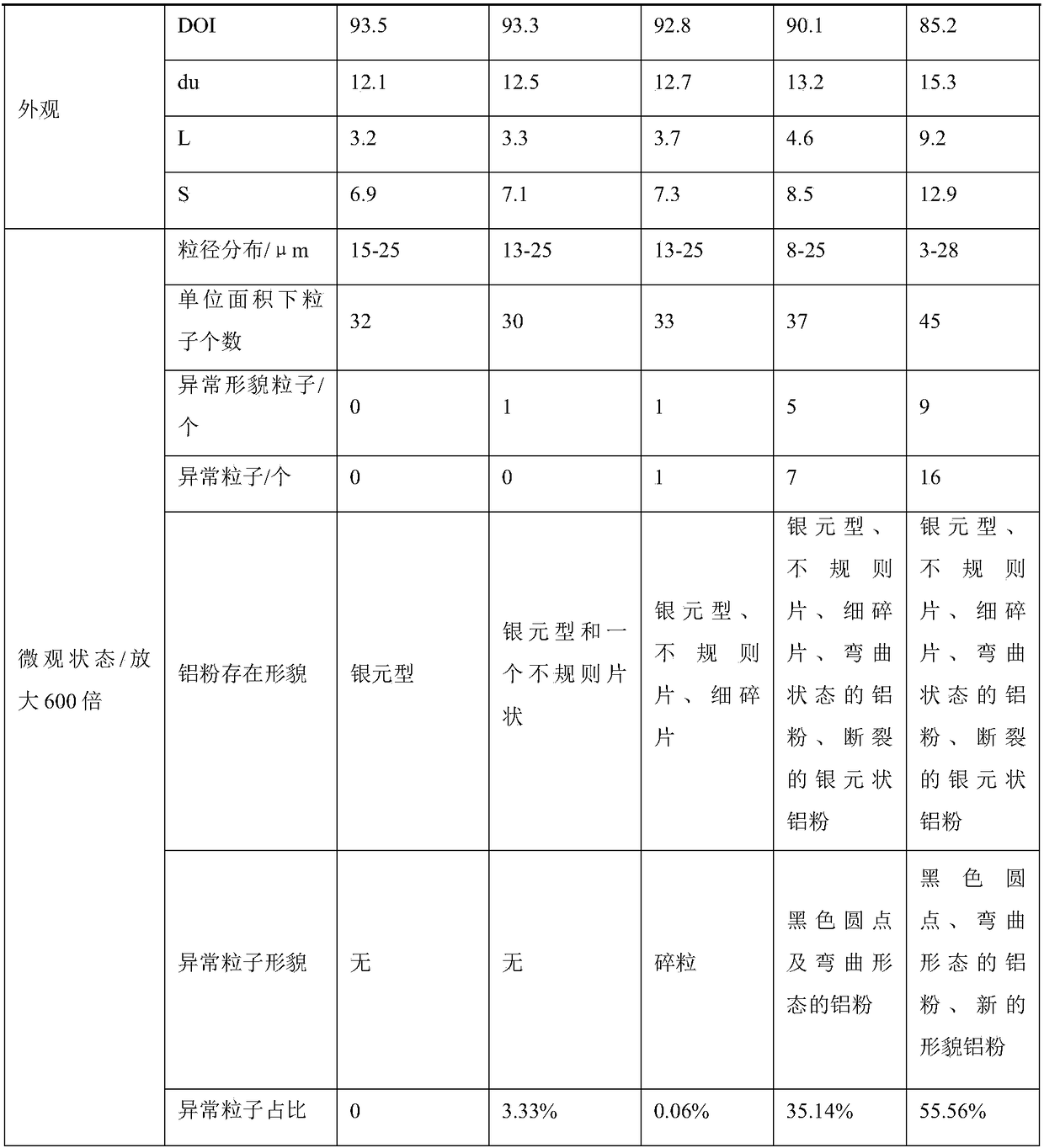

Method for detecting circulating stability of coating

InactiveCN109211770AHarsh conditionsThe result matchesWeather/light/corrosion resistanceCooking & bakingCyclic process

The invention discloses a method for detecting the circulating stability of a coating. The method comprises the following steps: dividing a coating to-be-detected into two parts, wherein one part is used as a comparative sample, and the other part is put into a coating storage tank of a thoroughly cleaned circulating pipeline device; performing parameter setting on the circulating pipeline deviceto perform circulating on the coating; performing sampling detection on the coating during circulating; separately detecting the performance of samples taken out at a plurality of different preset time points during circulating, and comparing the performance of the samples with the performance of the comparative sample; meanwhile, spraying the samples taken out at a plurality of different preset time points; performing baking according to a predetermined requirement, testing the performance of the samples after baking, and comparing them with the comparative sample. According to the method fordetecting the circulating stability of the coating, a coating resistance circulating pump and a dispersion equipment shearing are simulated from parameters of a circulating experiment equipment, i.e., the stirring speed, the circulating time, the coating temperature, the pressure, the pipeline length and the like, so that the obtained results are more consistent with actual conditions.

Owner:LANGFANG NIPPON PAINT

Magnetic head test tool suitable for various types of magnetic heads

ActiveCN112542182ATest stabilityTesting the limits of performanceFunctional testing of recording headsStructural engineeringConveyor belt

The invention relates to the technical field of magnetic head detection, and provides a magnetic head test tool suitable for various types of magnetic heads. The device comprises a frame, an upper supporting plate and a lower supporting plate are arranged at the left end and the right end of the frame, a screw is rotated to enable a magnetic strip plate to slide up and down on a sliding rod, multiple sets of magnetic strips adhere to the upper end face of the magnetic strip plate, a vertical plate is arranged in the frame, and a set of rollers are rotationally connected between the vertical plate and the frame; each set of rollers is in transmission connection with a conveyor belt; a sliding plate is placed between the conveying belts on the front side and the rear side, a magnetic head groove hole is formed in the middle of the sliding plate, the magnetic head groove hole, the frame and the concentric-square-shaped baffle jointly form a groove, a magnetic head is placed in the groove,and a connector bar is arranged on one side of the sliding plate and electrically connected with the magnetic head. And meanwhile, the connector bar is electrically connected with control equipment capable of displaying read information of the magnetic head. The magnetic head testing tool is suitable for performance testing of magnetic heads of different specifications and different types, the universality of the magnetic head testing tool is improved, and the performance stability and the performance limit of the magnetic head can be tested.

Owner:全南群英达电子有限公司

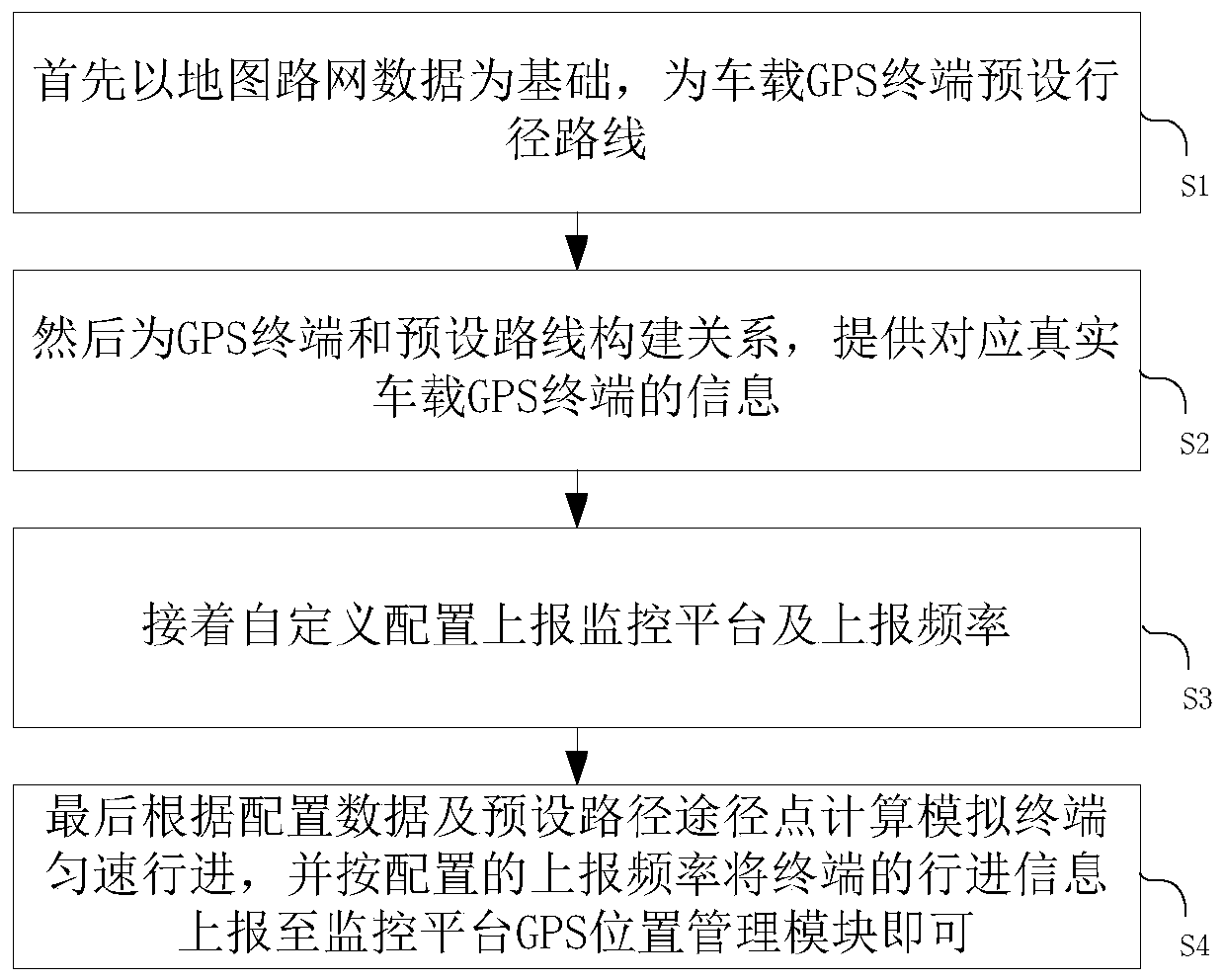

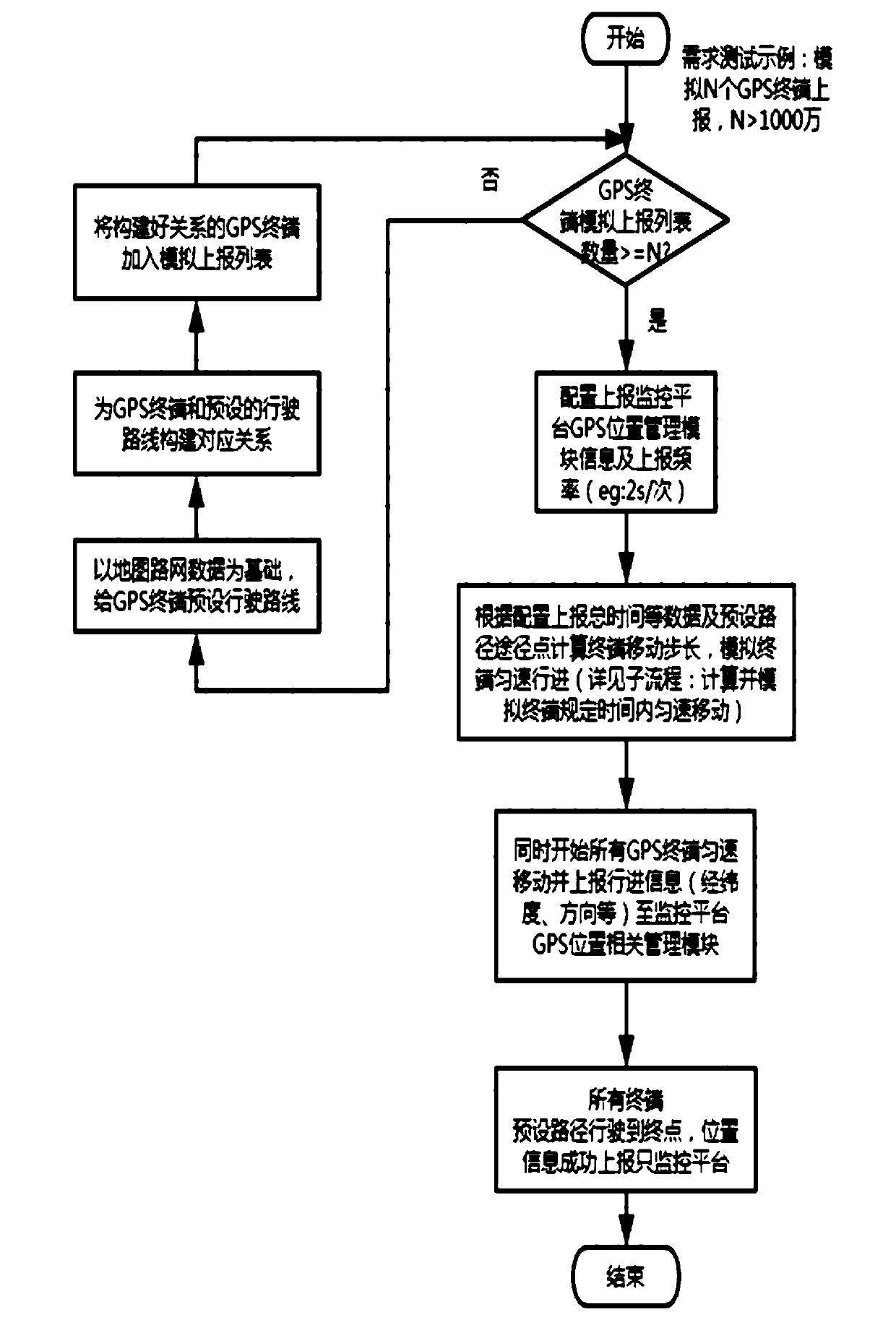

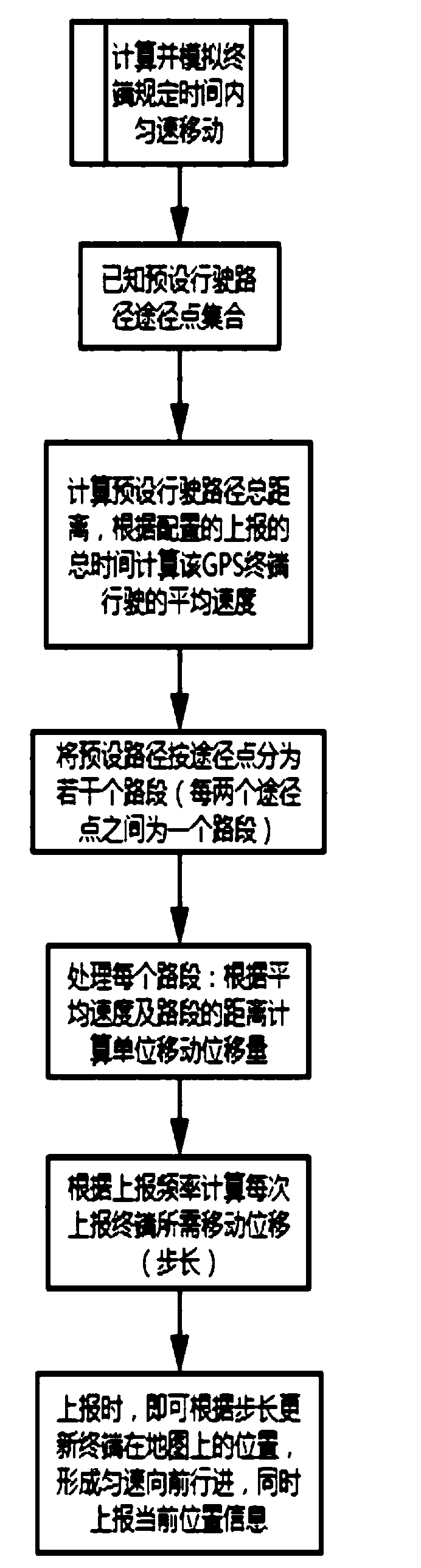

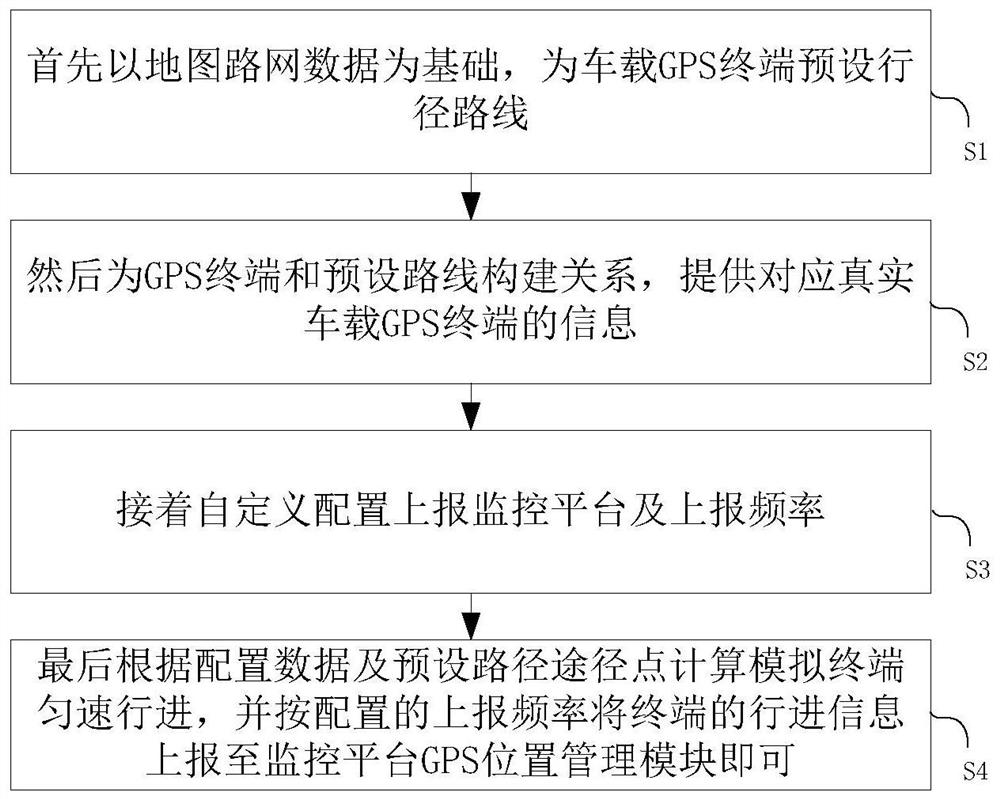

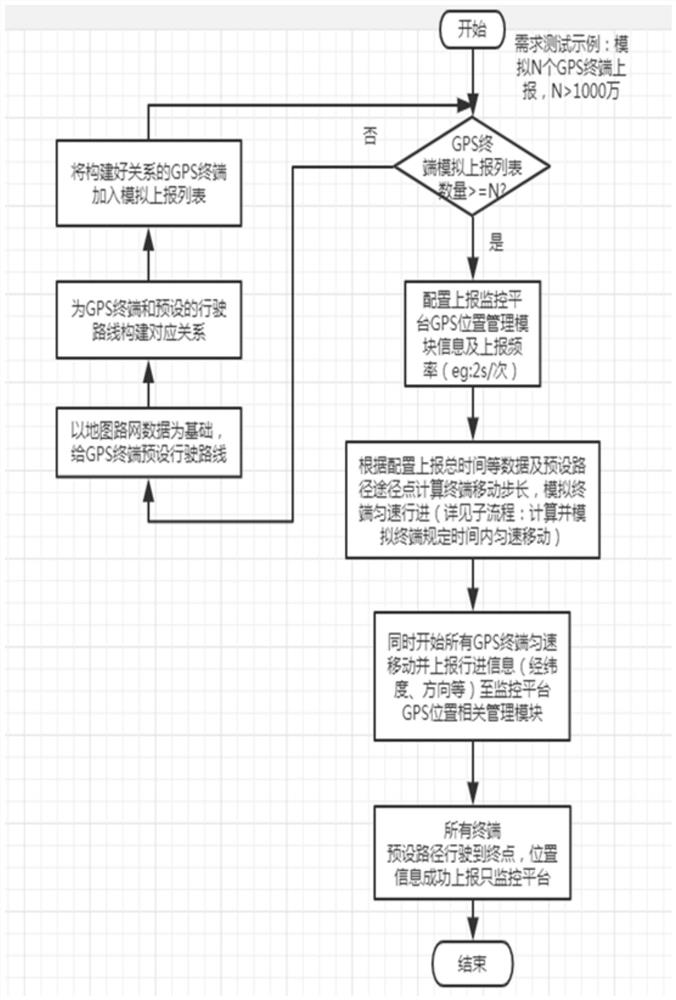

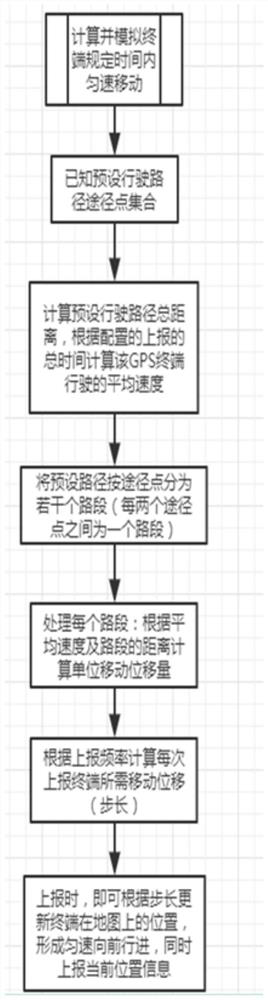

Vehicle-mounted GPS terminal simulation reporting method and device, computer equipment and medium

ActiveCN110730423ATest stabilityConcurrent Processing Capability TestParticular environment based servicesLocation information based serviceIn vehicleComputational simulation

The invention relates to a vehicle-mounted GPS terminal simulation reporting method and device, computer equipment and a medium, and the method comprises the steps: presetting a travel path for a vehicle-mounted GPS terminal based on map road network data; constructing a relationship between the GPS terminal and a preset route, and providing information corresponding to a real vehicle-mounted GPSterminal; configuring a reporting monitoring platform and reporting frequency; and according to the configuration data and a preset path path point, calculating and simulating the constant-speed advancing of the terminal, and reporting the advancing information of the terminal to a monitoring platform GPS position management module according to the configured reporting frequency. According to theinvention, a large amount of vehicle-mounted GPS terminals can be simulated according to actual requirements, different vehicle-mounted GPS terminals do not need to be installed on different vehicles,actual driving is not needed, and the stability, concurrent processing capability and the like of the vehicle monitoring platform can be effectively tested with very low cost.

Owner:GENEW TECH

Lateral pushing strength testing method and equipment for electric bed

InactiveCN110864922ATest stabilityTest wear rateStructural/machines measurementControl systemClassical mechanics

The invention discloses a lateral pushing strength testing method and equipment for an electric bed. The method comprises the steps of performing sample installation, load simulation, test starting and result evaluation; and the equipment comprises a test area for placement of a sample bed and a control system for setting test parameters. By simulating the use state of the electric bed, lateral pushing is applied to the electric bed, the stability of the electric bed legs is detected, the loss rate of the bed legs after the electric bed legs are subjected to lateral pushing in a standard rangeis measured, and the service life of the electric bed is further evaluated according to the test parameters.

Owner:KEESON TECH CORP LTD

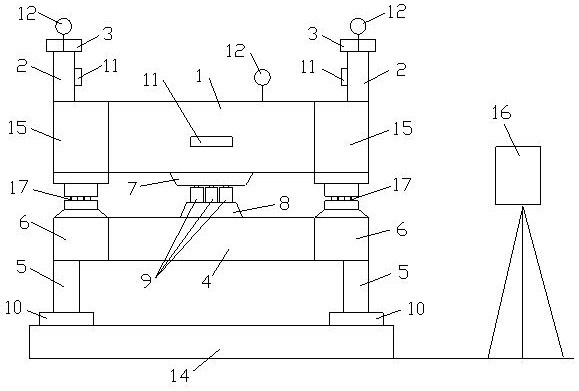

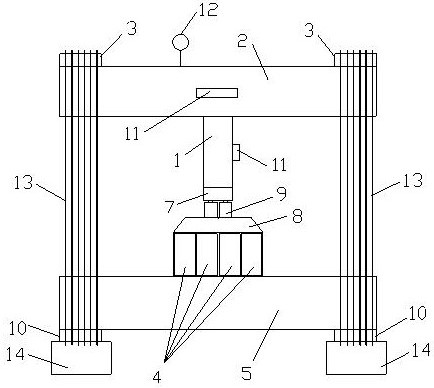

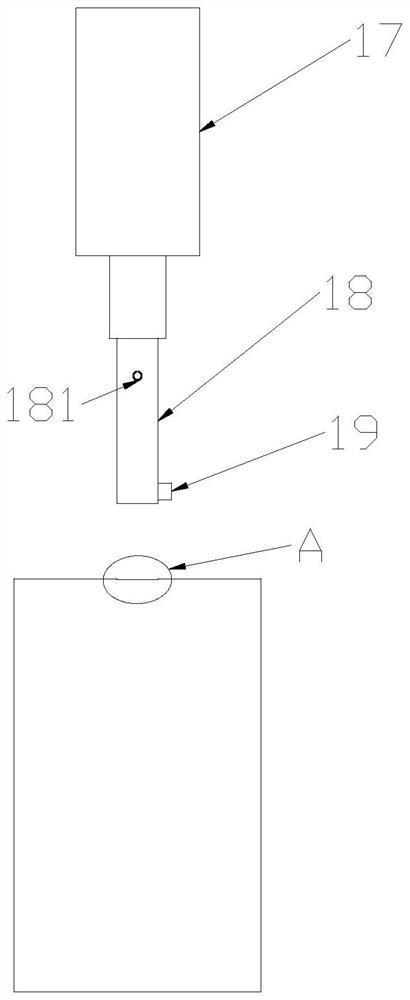

Simulation test equipment and method for super-load anchor pile cross beam counter-force device

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

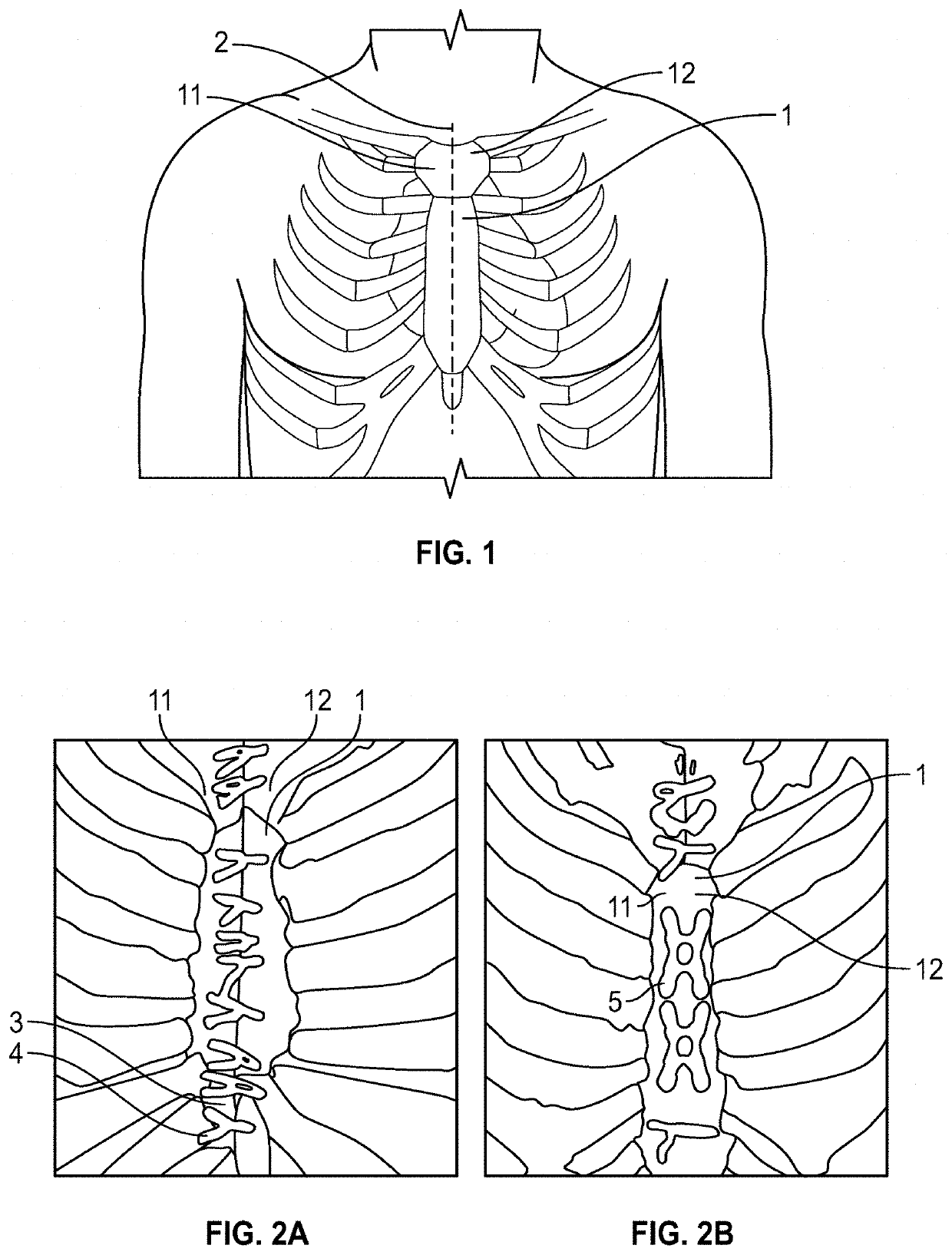

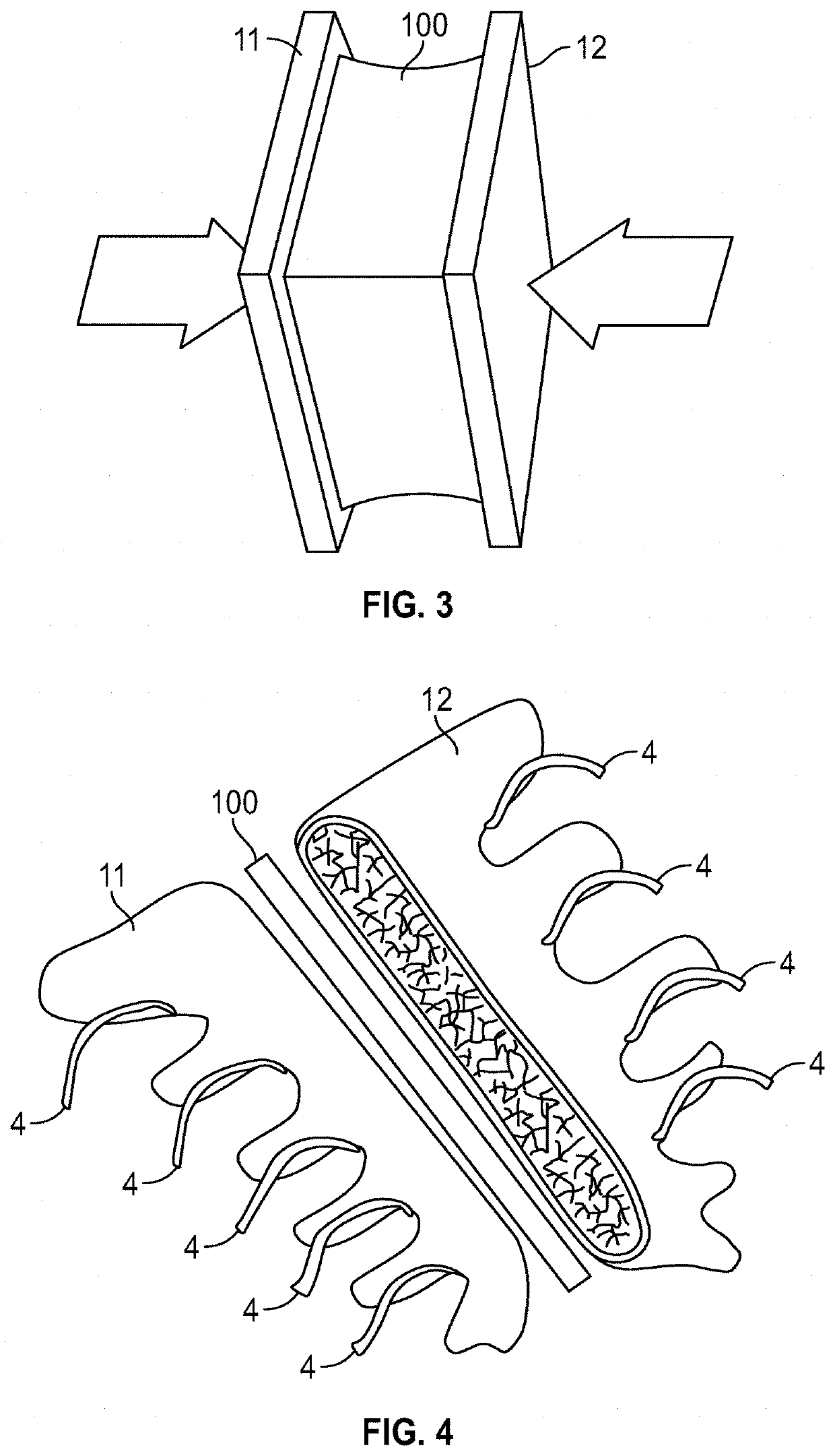

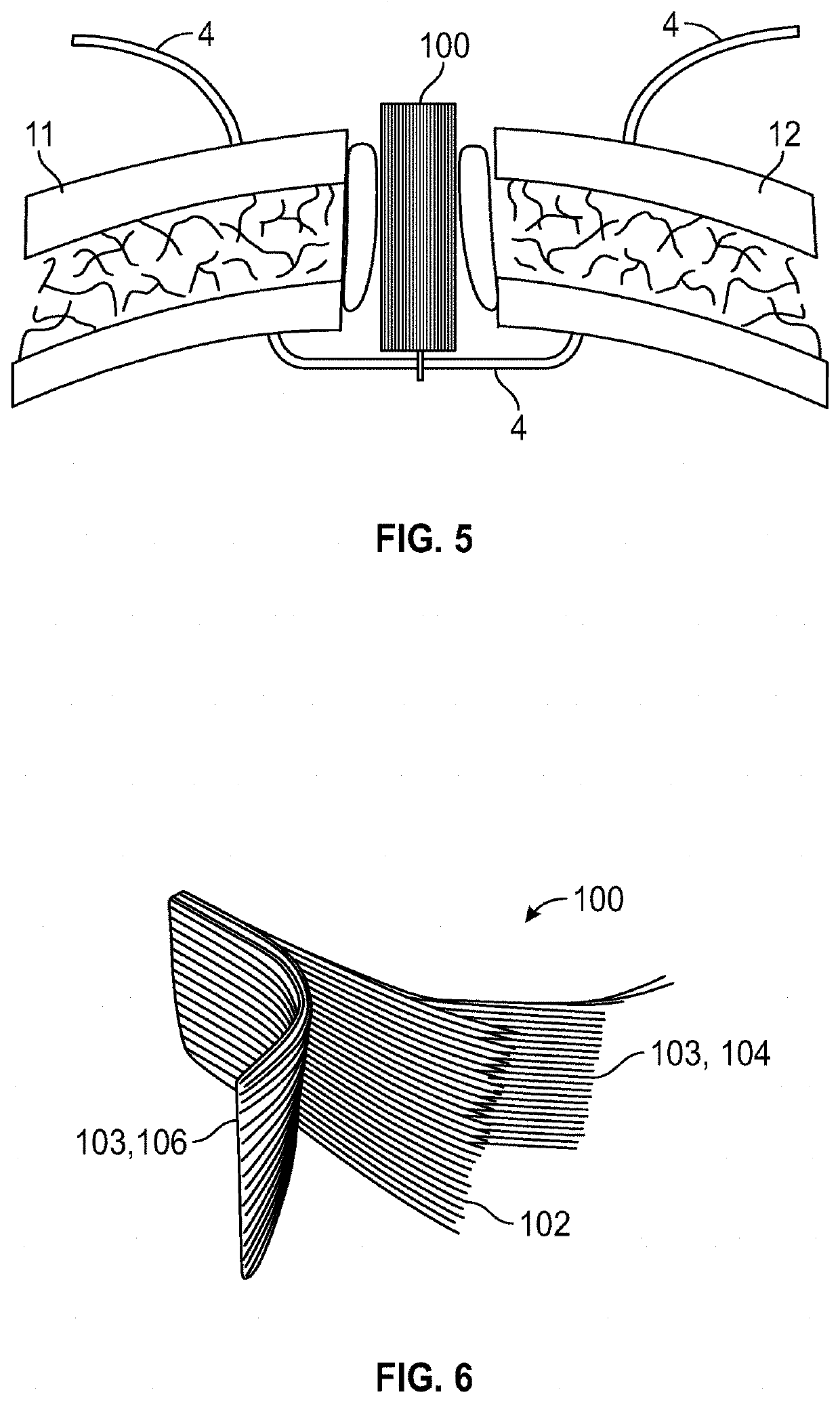

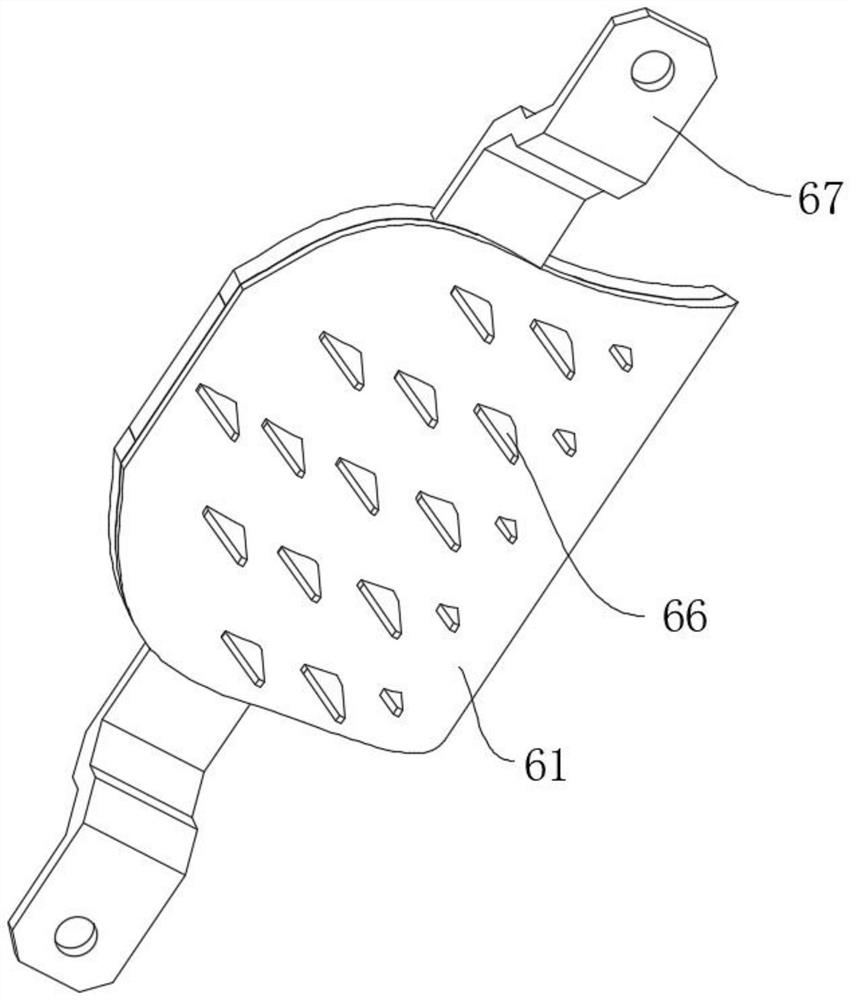

System and method to fuse bone

Systems and methods include a method to fuse two sections of bone. The method includes various operations such as accessing the chest cavity (e.g., by severing the sternum) and preparing the sternal edges of the two sections of bone. Sternal wires are implanted around the two sections of bone to create a cradle in a space between the two sections of bone. Cancellous bone tissue may be harvested from the patient and used to hydrate an implant before trimming the implant and / or placing the implant in the cradle. The sternal wires are tightened to compress the implant between the two sections of bone; and the ends of the sternal wires are tied together to create a sternal structure comprised of the implant tightly compressed between the two sections of bone. The sternal construct can act as a bone gasket to improve healing and fusing for the two sections of bone.

Owner:CRYOHEART LAB INC

Vehicle-mounted GPS terminal simulation reporting method and device, computer equipment, and medium

ActiveCN110730423BTest stabilityConcurrent Processing Capability TestParticular environment based servicesLocation information based serviceIn vehicleComputational simulation

This application relates to a vehicle-mounted GPS terminal simulation reporting method and device, computer equipment, and media. The method includes: based on map road network data, preset a route for a vehicle-mounted GPS terminal; build a relationship between a GPS terminal and a preset route, and provide Corresponding to the information of the real vehicle GPS terminal; configure the reporting monitoring platform and reporting frequency; calculate the simulated terminal moving at a constant speed according to the configuration data and preset route points, and report the terminal’s traveling information to the monitoring platform GPS position management module according to the configured reporting frequency . The present invention can simulate a vehicle-mounted GPS terminal with a large amount of data according to actual needs, without installing different vehicle-mounted GPS terminals on different vehicles, and without actually driving, and can monitor the stability of the vehicle monitoring platform at a very low cost. Concurrent processing capabilities, etc. are effectively tested.

Owner:GENEW TECH

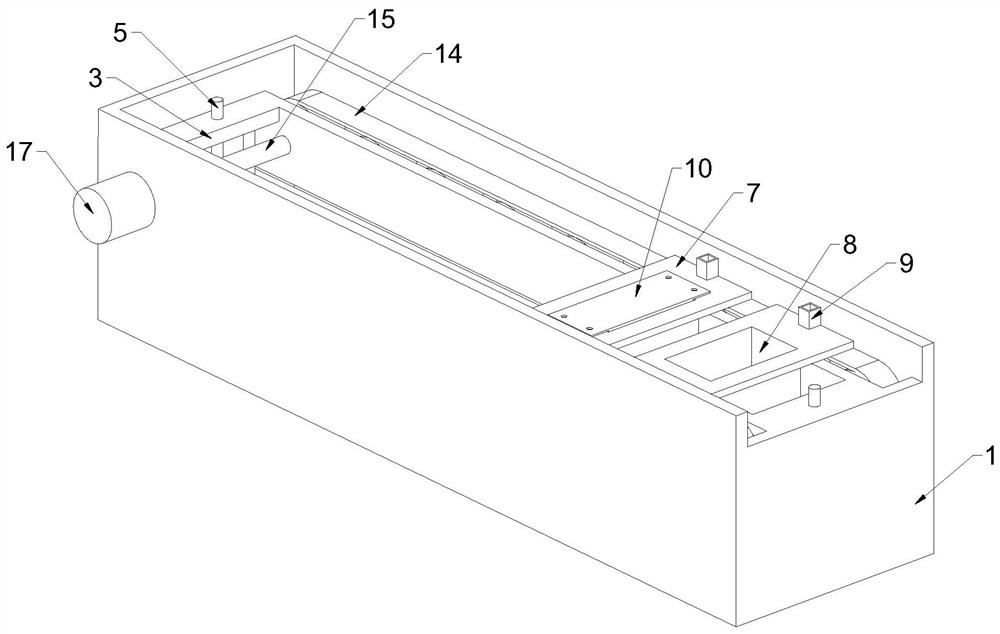

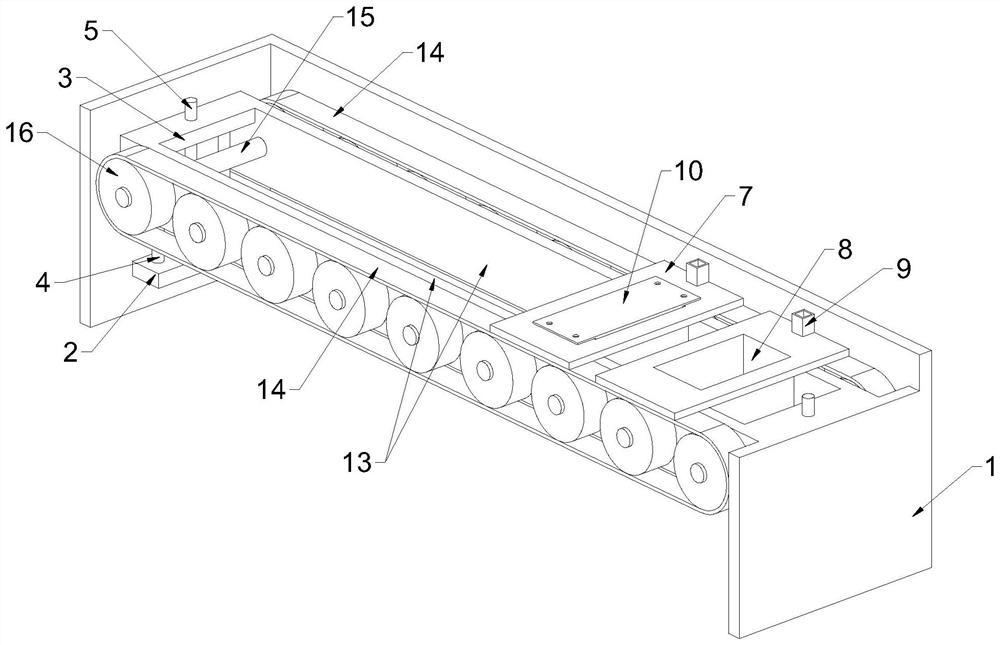

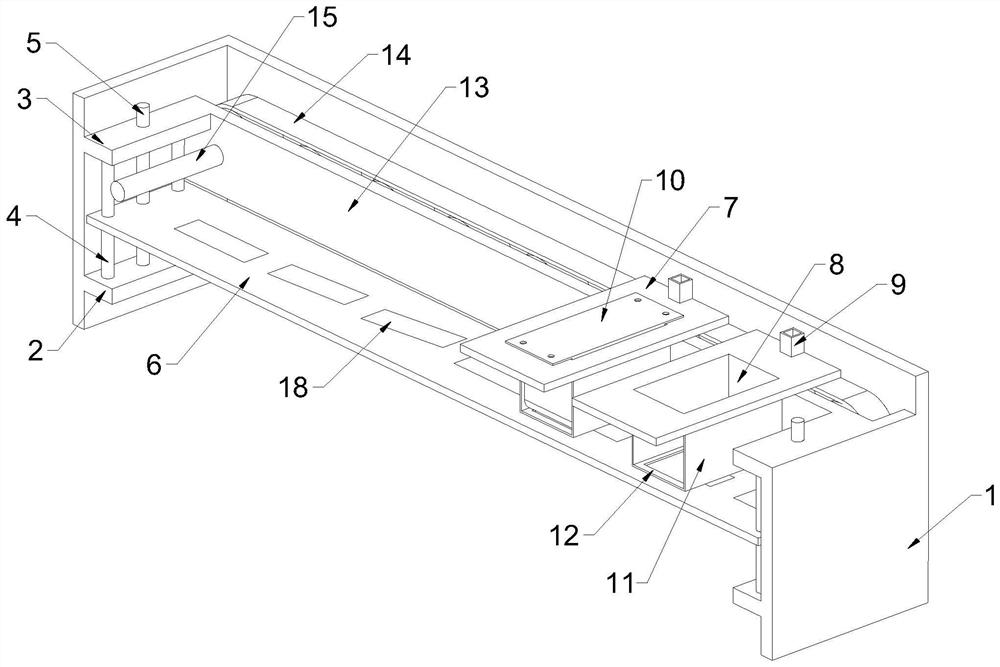

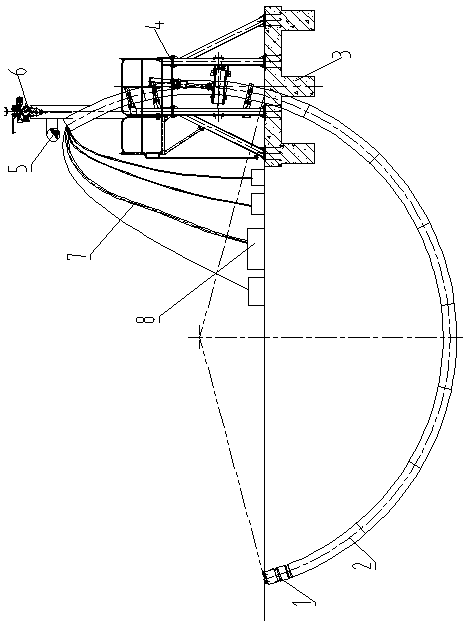

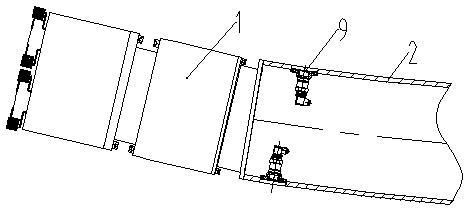

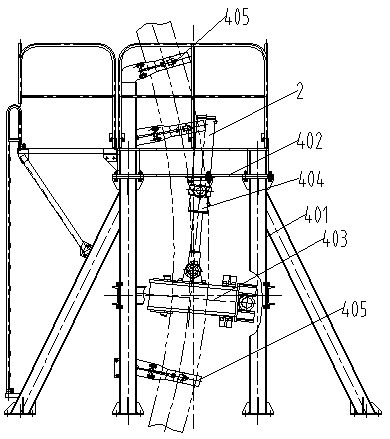

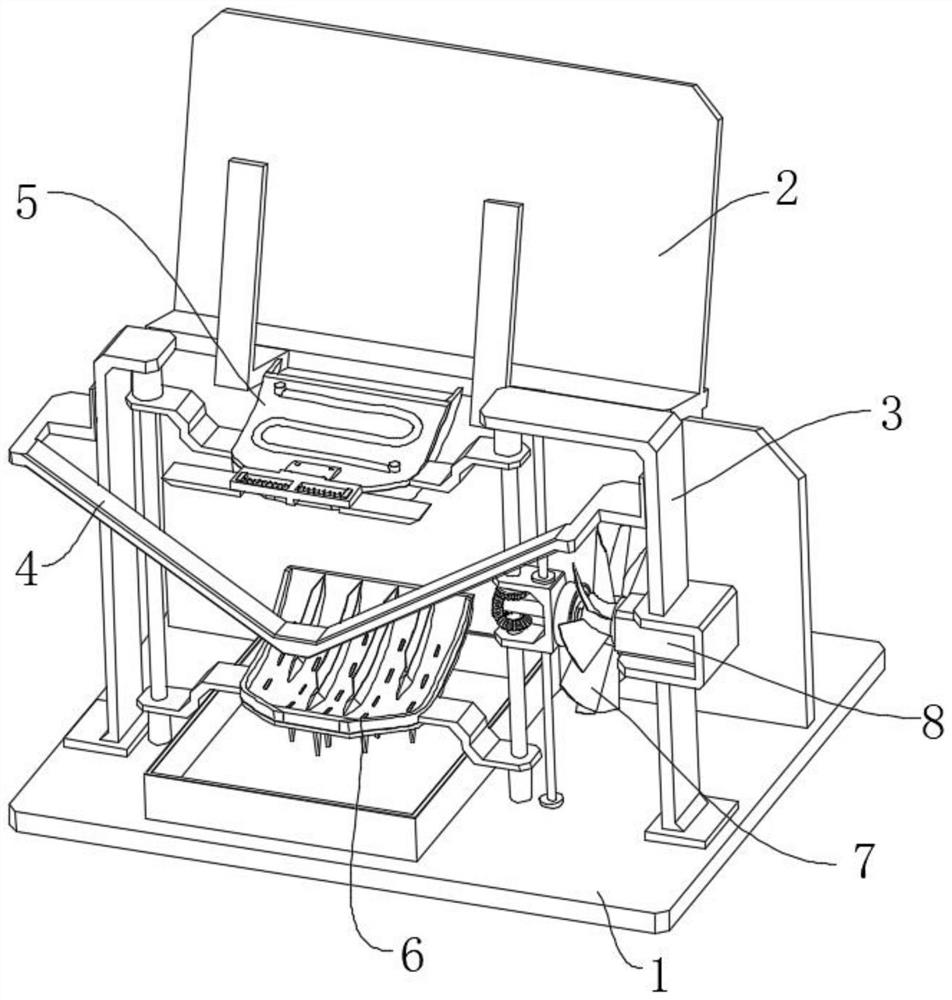

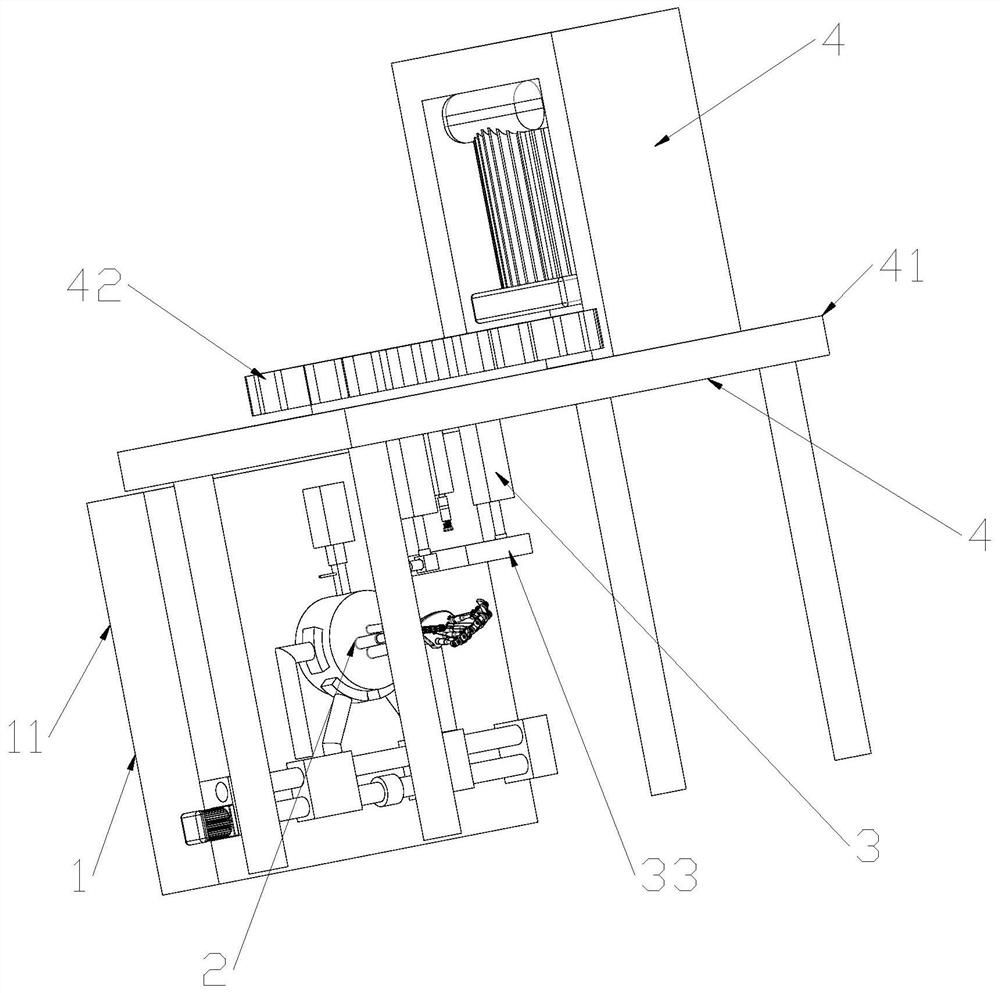

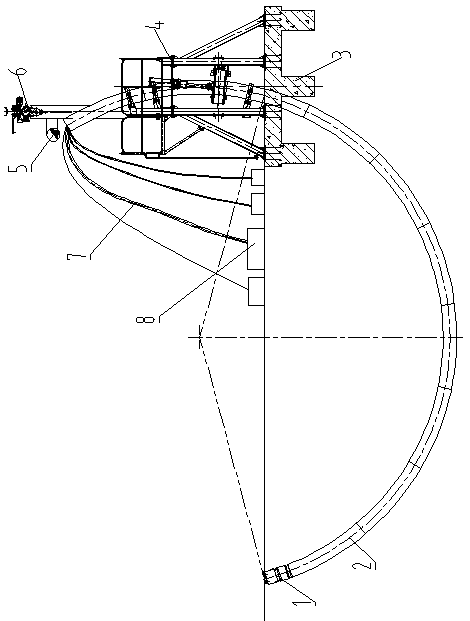

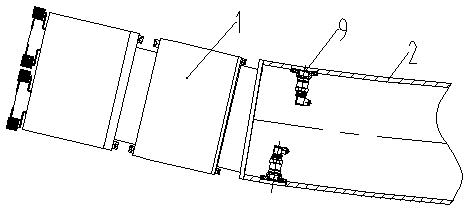

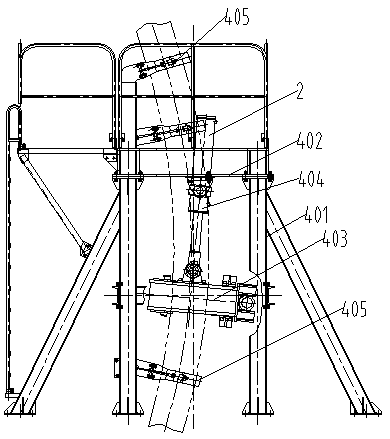

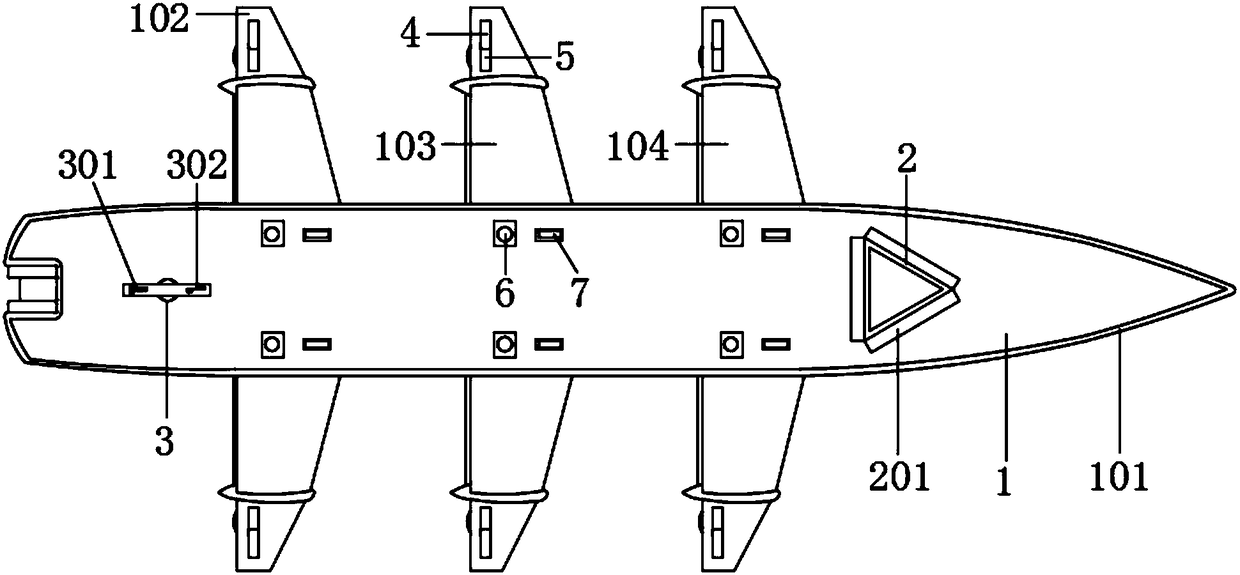

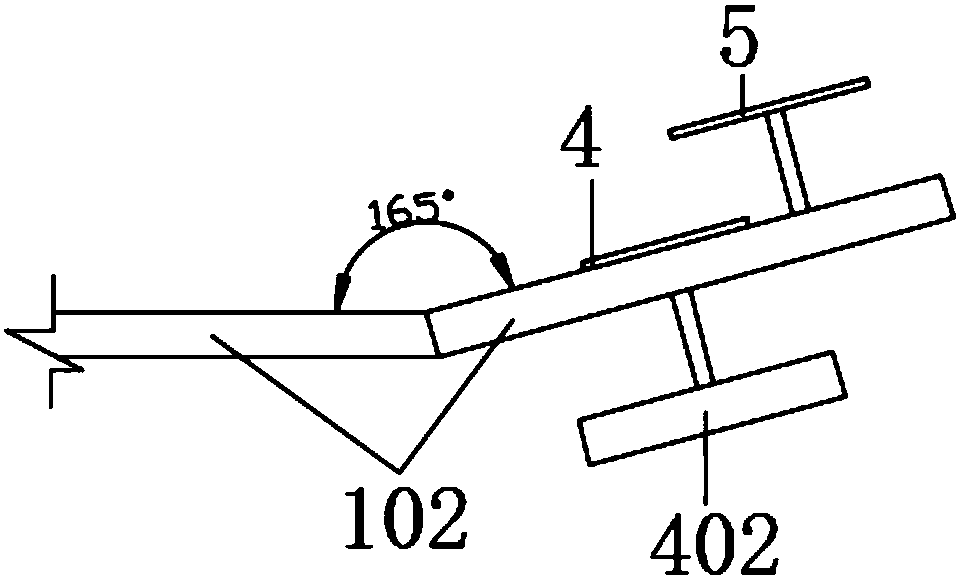

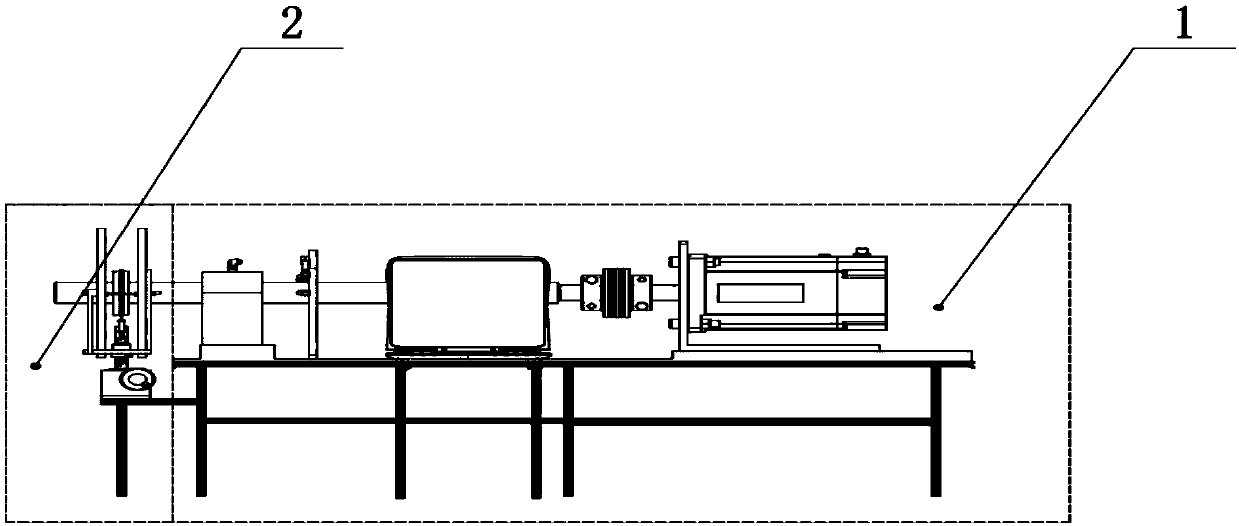

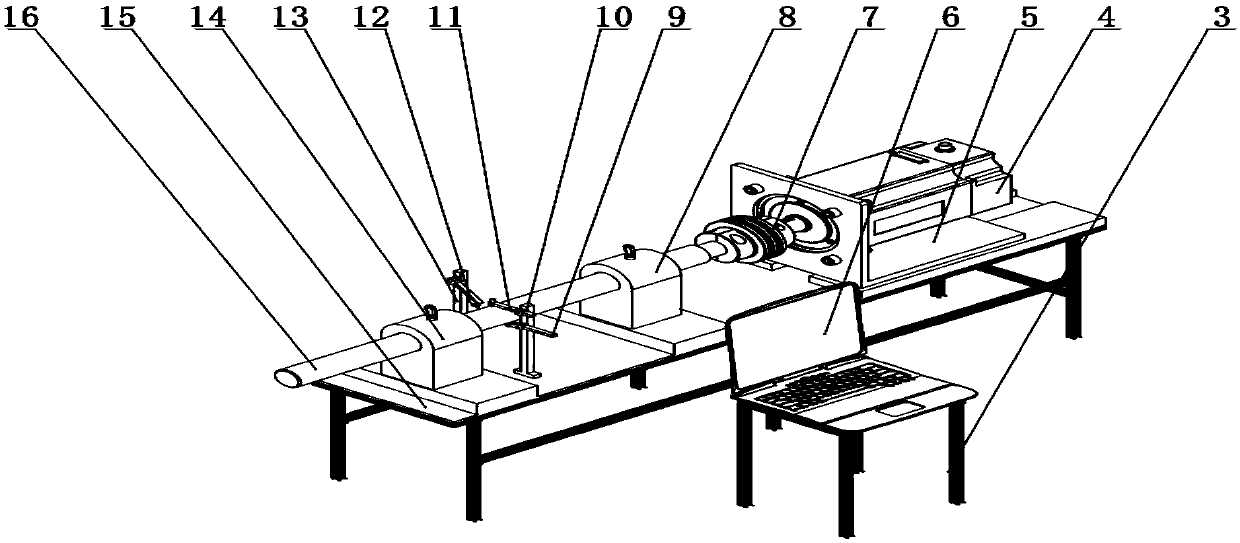

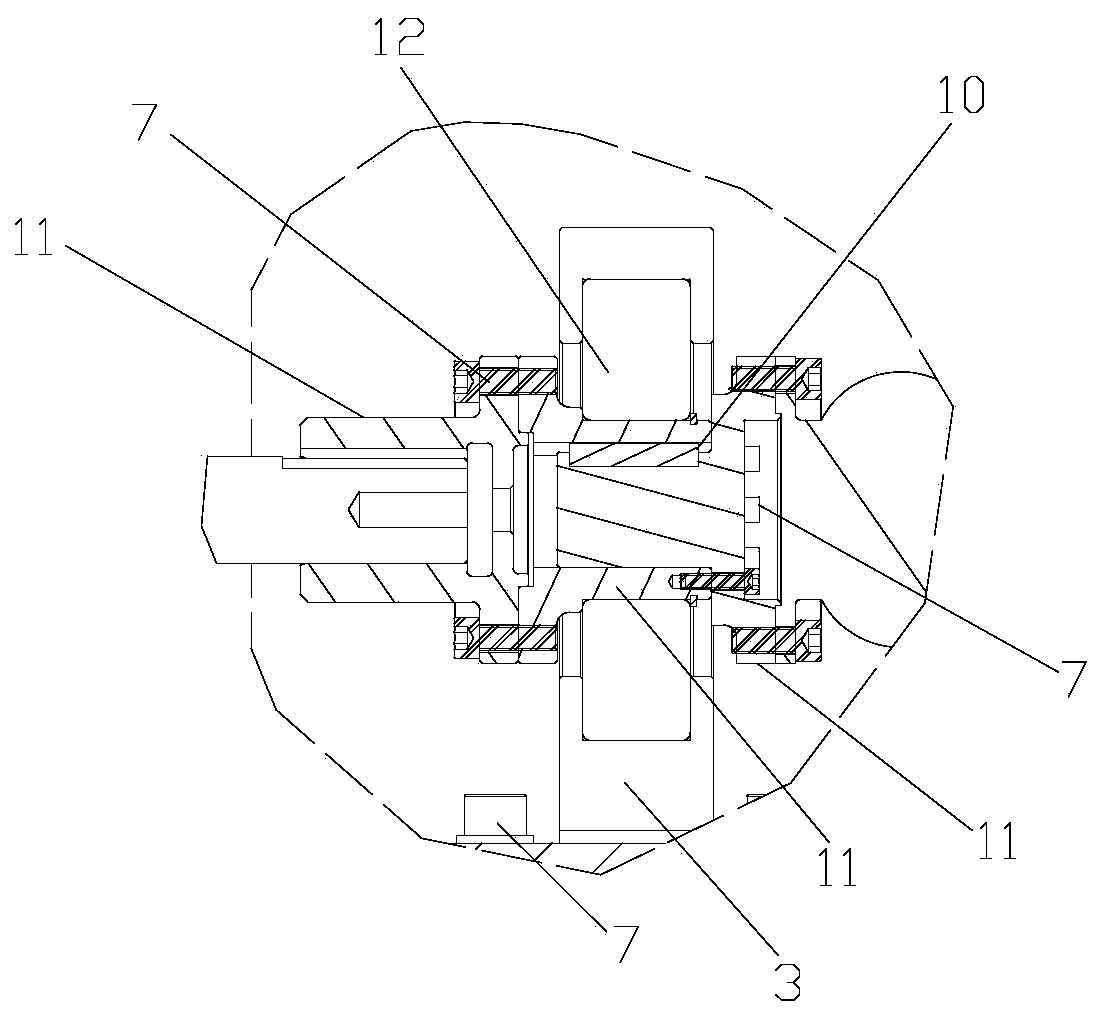

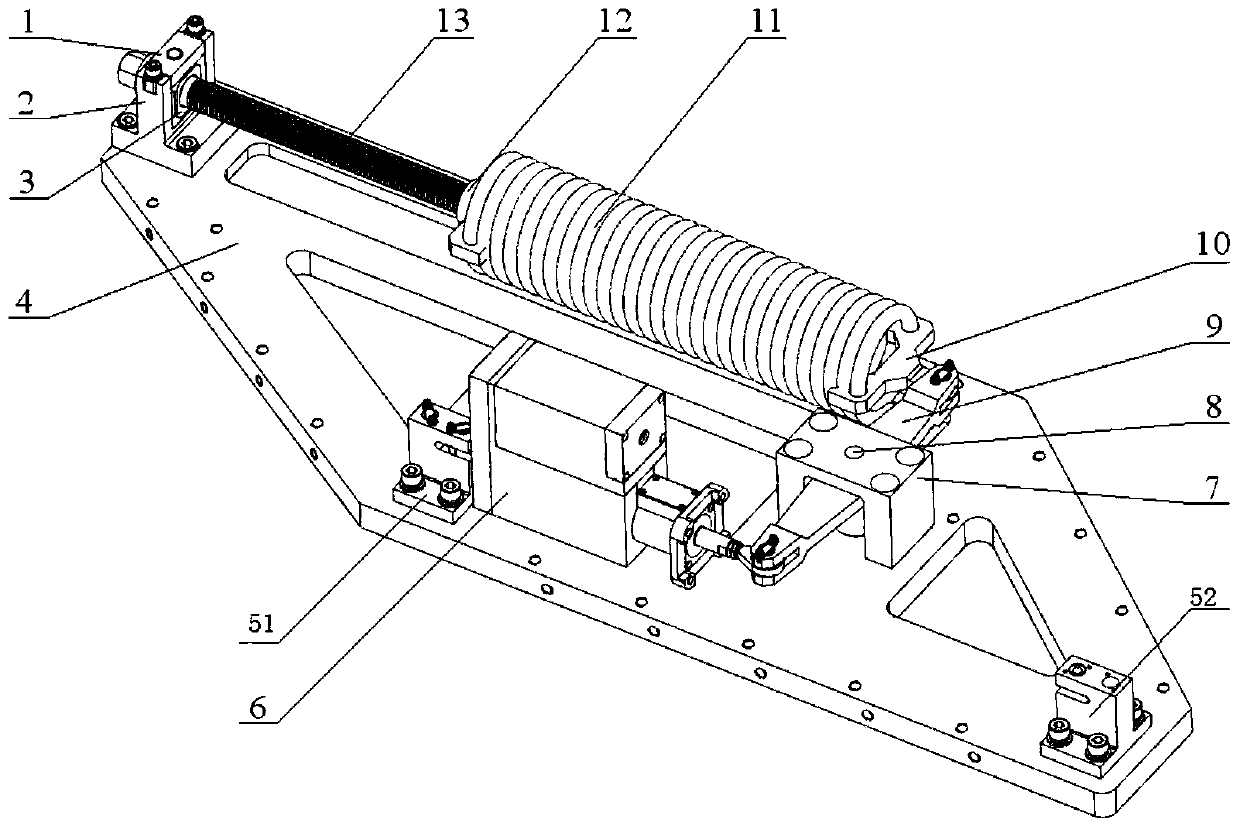

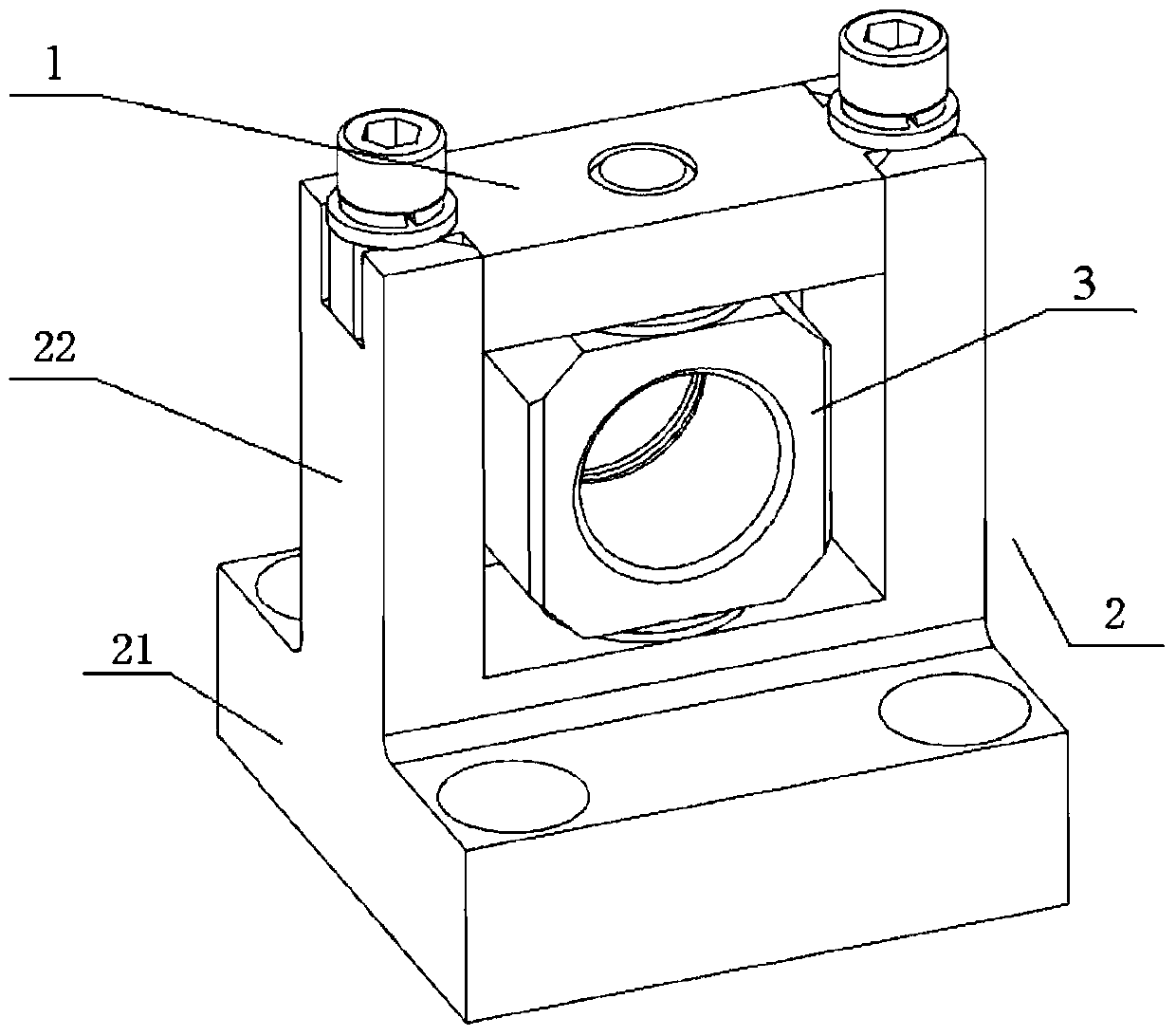

A kind of test device and test method of curved pipe curtain machine

ActiveCN108871829BCheck operational reliabilityTest stabilityStructural/machines measurementTunnelsLine tubingArchitectural engineering

The invention discloses a device and method for testing a curved pipe-roofing machine, and solves the problems that the curved pipe-roofing machine in the prior art is difficult in jacking, deslaggingand posture control, and there is shortage of theory and experiment basis. The device comprises a main unit, a steel pipe joint, and a jacking mechanism. A pile foundation for supporting the jackingmechanism is disposed on the ground, and the jacking mechanism is fixedly connected with the foundation pile. The foundation pile is provided with a cantilever suspension, and the main unit is disposed at one end of the steel pipe joint, wherein the other end of the steel pipe joint passes through the jacking mechanism. The jacking mechanism is provided with a guide mechanism and auxiliary equipment. The main unit is connected with the auxiliary equipment through a pipe in the steel pipe joint, and the guide mechanism is corresponding to the steel pipe joint. The cantilever suspension is disposed at one side of the steel pipe joint, and is connected with the steel pipe joint. According to the invention, the working conditions of underground excavation are simulated through a ground test, thereby achieving the testing of the operation performances of all systems of the curved pipe-roofing machine and the verifying of the construction precision and design reasonability while achieving the jacking of the curved steel pipe joint.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

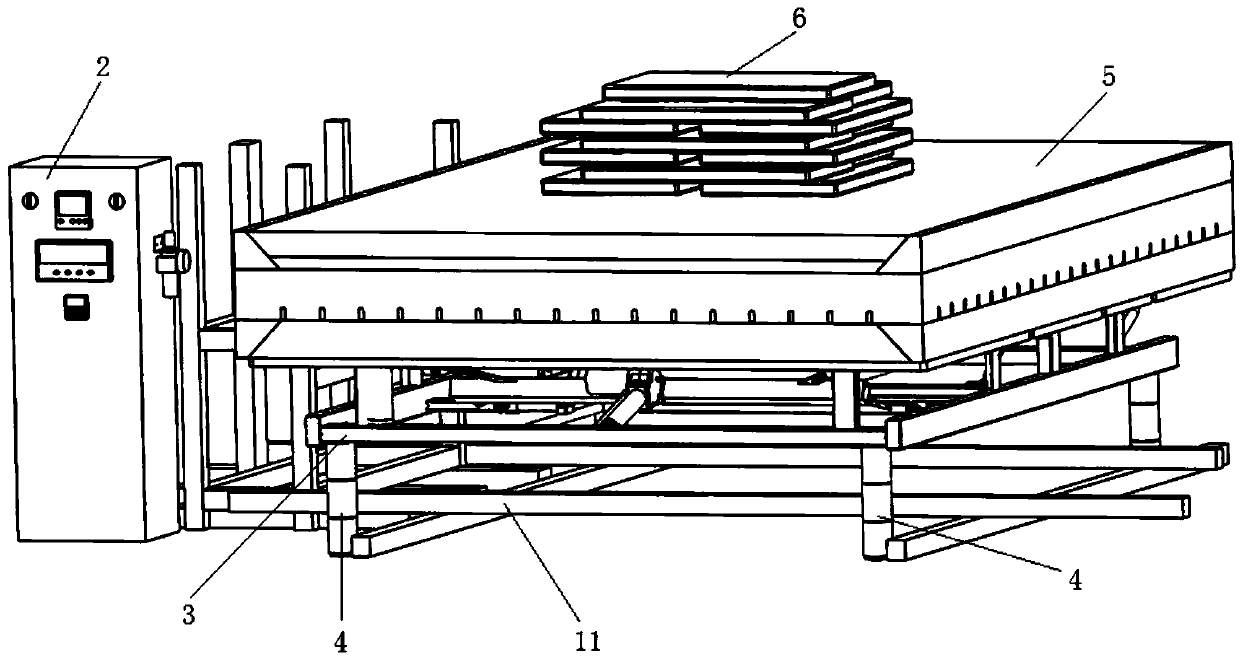

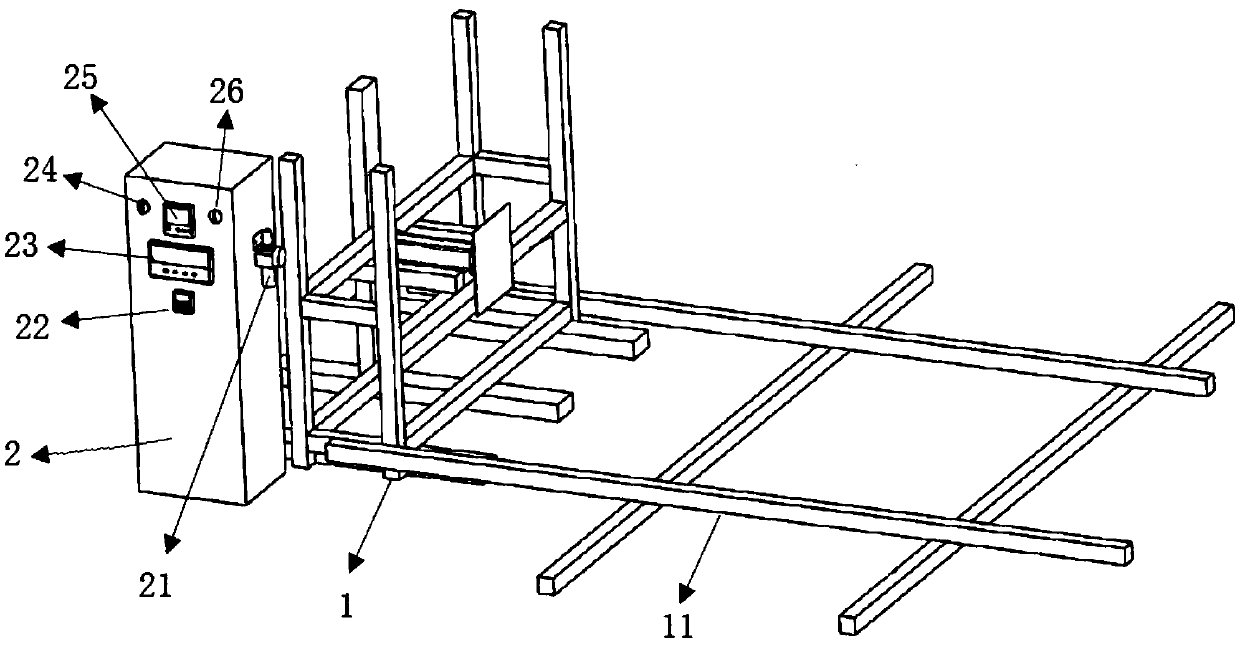

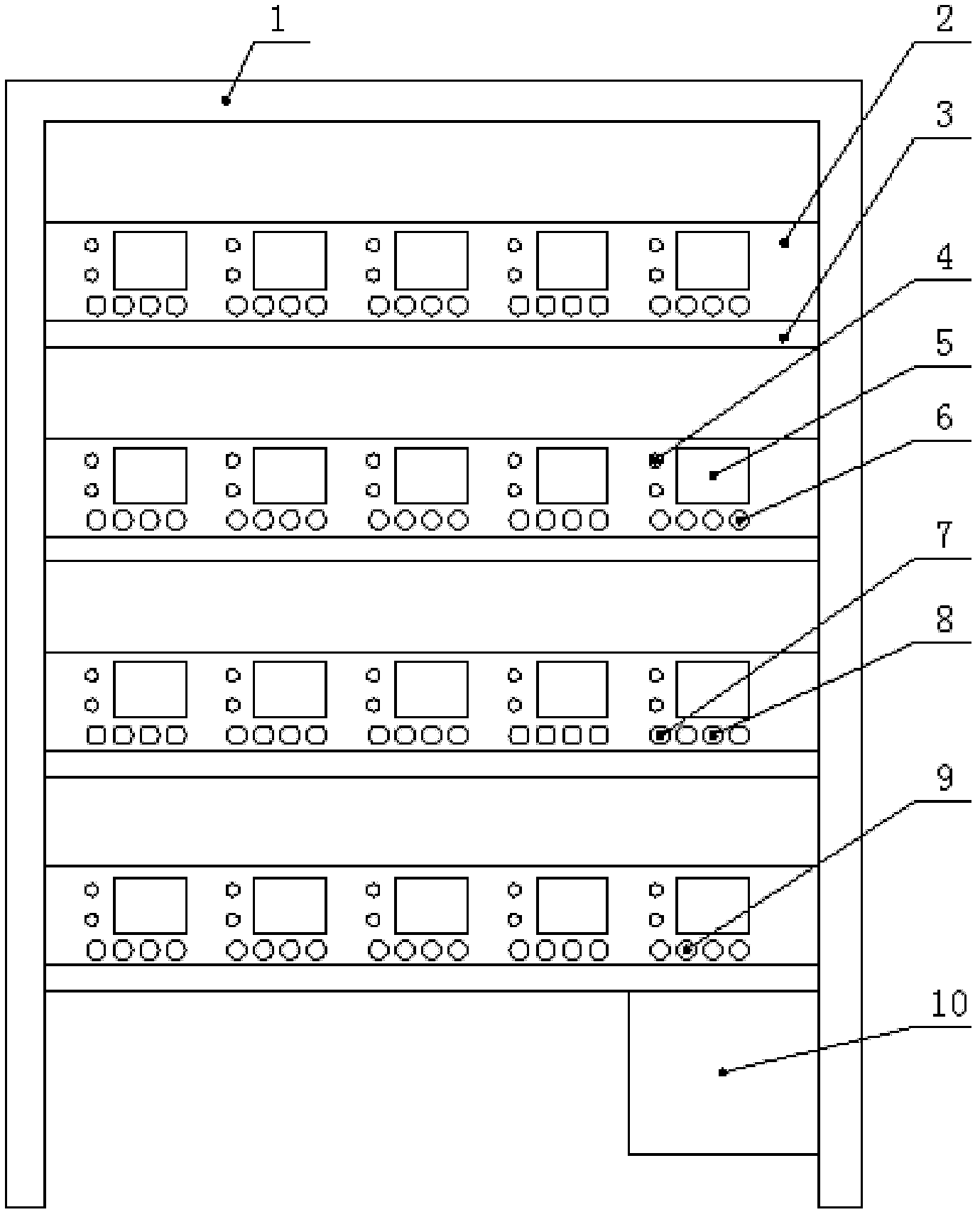

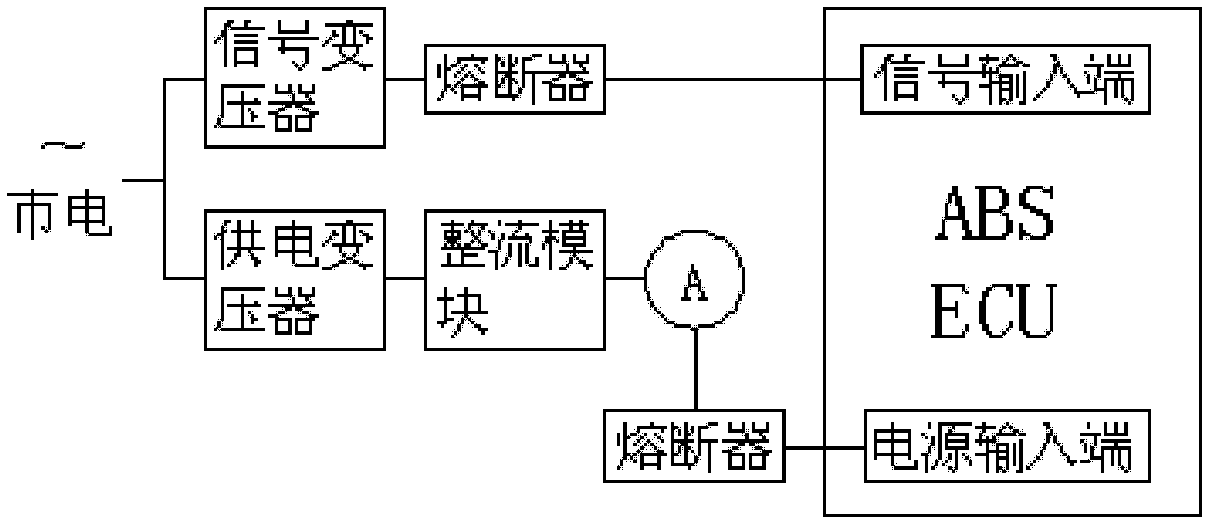

Test stand for aging of ECU utilized by ABS of vehicle

InactiveCN102354202BTest stabilityImprove work efficiencyElectric testing/monitoringElectricityTransformer

The invention relates to a test stand for aging of an ECU utilized by an ABS of a vehicle. The test stand comprises a framework, support plates, vertical plates, a power supply unit and a plurality of test units; the plurality of support plates are installed in the framework, wherein the plurality of support plates are in parallel with each other and there are intervals between the support plates; the vertical plates are respectively installed at a rear end of each the support plates; and the plurality of support plates are installed at each the vertical plate. According to the invention, a first signal binding post and a second signal binding post in each test unit are connected to a signal input terminal of an ECU through cables; a power supply binding post and a grounding terminal in each the test unit are connected with a power supply input terminal of the ECU; and commercial power is converted into a 0.5-volt alternating current signal with 50 HZ through a signal transformer in apower supply unit and then ECU motions are triggered continuously by the alternating current signal, so that stability and correctness of the ECU during intensely working are tested. Besides, a plurality of ECUs can be simultaneously measured through tests in proper order, so that the tests can be operated conveniently and the working efficiency can be improved.

Owner:鼎佳(天津)汽车电子有限公司

A method of main-standby switching of simulation system based on railway safety communication protocol

ActiveCN112615728BResolve interruptionImprove test stabilityRailway traffic control systemsTransmissionData synchronizationSecure communication

Owner:CASCO SIGNAL

Strength detection equipment based on 5G dual-polarized antenna

InactiveCN114136873AEffective detection of resistanceImprove accuracyWeather/light/corrosion resistanceEngineeringMechanical engineering

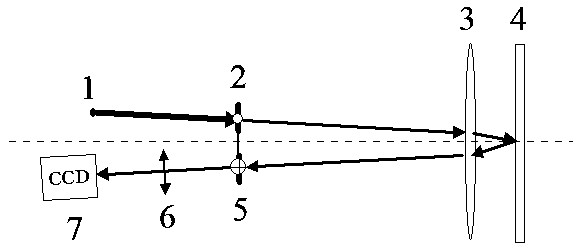

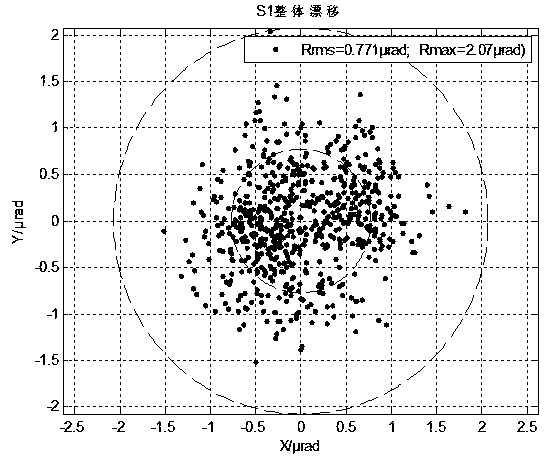

A mirror drift stability testing system and method

ActiveCN107228755BTest stabilityRich relevant informationTesting optical propertiesLaser technologyLight beam

The invention belongs to the field of laser technologies, and more particularly relates to a reflector angle drift stability testing system and a reflector angle drift stability testing method. According to the reflector angle drift stability testing system and the reflector angle drift stability testing method, light beam pointing stability is converted into variation of object-image relative positions by adopting an imaging design, and the influence of a light source and a diagnostic system on tests is eliminated; and by adopting an optical design, two feature objects associated with reflector stability are placed on the same plane for solid connection, thereby eliminating influence on the independent stability of the feature objects. The reflector angle drift stability testing system and the reflector angle drift stability testing method are suitable for stability tests of various kinds of optical elements in large-sized laser devices.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

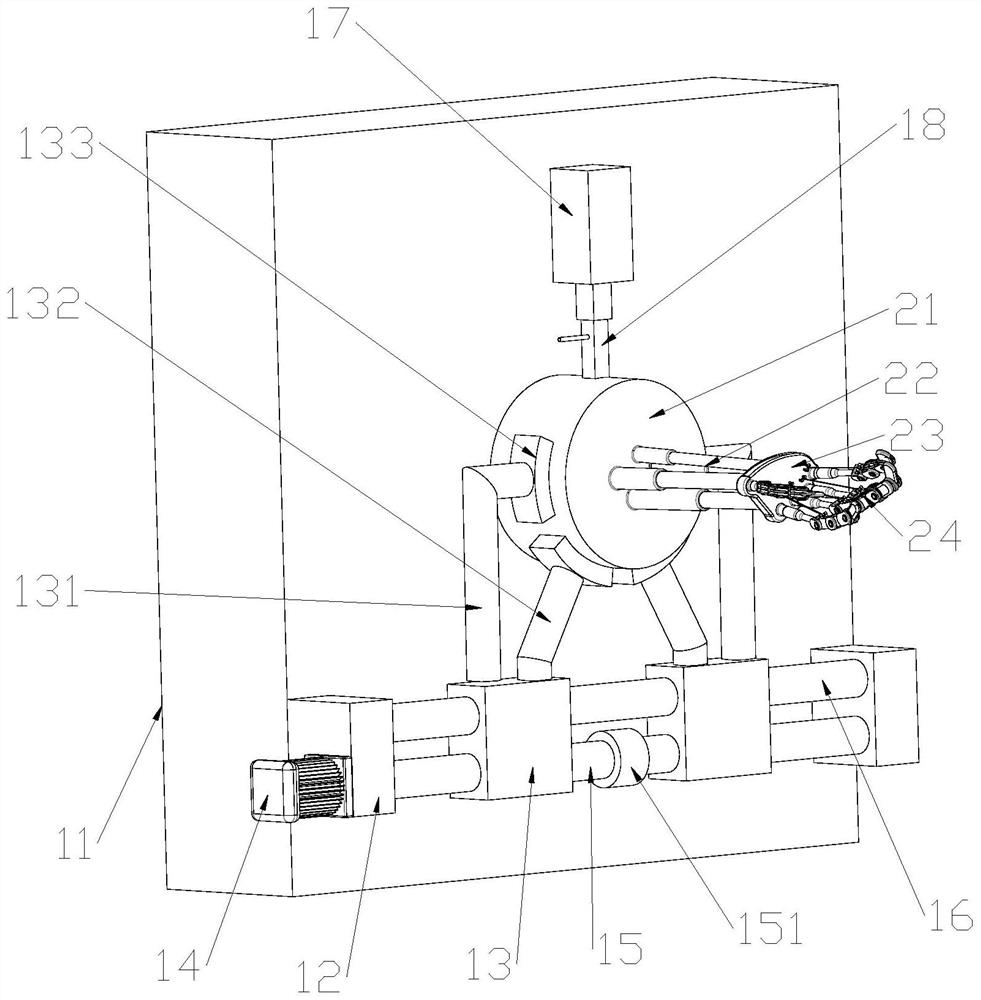

Bionic artificial muscle pressure resistance detection device and method

ActiveCN114536310AEasy to installEasy to disassembleProgramme-controlled manipulatorHuman bodyMedicine

The invention relates to the technical field of artificial muscles, in particular to a pressure resistance detection device and method for bionic artificial muscles. The device comprises a clamping mechanism, an artificial muscle assembly, a pressure assembly and a mounting frame. When the artificial muscle is applied to the human body exoskeleton device to carry heavy objects, fixing of the mechanical claw has clamping force and upward drawing force, the designed clamping mechanism can simulate the actual working condition and provide the clamping force and the upward drawing force, meanwhile, the designed clamping block can be better clamped in the base, and therefore the clamping force and the upward drawing force can be provided for the human body exoskeleton device. The device is very convenient to mount and dismount, and is suitable for detection experiments of pressure and impact force. The designed pressure assembly is matched with the mounting frame, the pressure direction of the pressure plate can be flexibly adjusted, meanwhile, impact force accidentally generated in the heavy object carrying process can be simulated through an impactor in the pressure experiment process, and the stability of the artificial muscle in the sudden accident is tested.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Device and method for testing curved pipe-roofing machine

ActiveCN108871829ACheck operational reliabilityTest stabilityStructural/machines measurementTunnelsAttitude controlEngineering

The invention discloses a device and method for testing a curved pipe-roofing machine, and solves the problems that the curved pipe-roofing machine in the prior art is difficult in jacking, deslaggingand posture control, and there is shortage of theory and experiment basis. The device comprises a main unit, a steel pipe joint, and a jacking mechanism. A pile foundation for supporting the jackingmechanism is disposed on the ground, and the jacking mechanism is fixedly connected with the foundation pile. The foundation pile is provided with a cantilever suspension, and the main unit is disposed at one end of the steel pipe joint, wherein the other end of the steel pipe joint passes through the jacking mechanism. The jacking mechanism is provided with a guide mechanism and auxiliary equipment. The main unit is connected with the auxiliary equipment through a pipe in the steel pipe joint, and the guide mechanism is corresponding to the steel pipe joint. The cantilever suspension is disposed at one side of the steel pipe joint, and is connected with the steel pipe joint. According to the invention, the working conditions of underground excavation are simulated through a ground test, thereby achieving the testing of the operation performances of all systems of the curved pipe-roofing machine and the verifying of the construction precision and design reasonability while achieving the jacking of the curved steel pipe joint.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

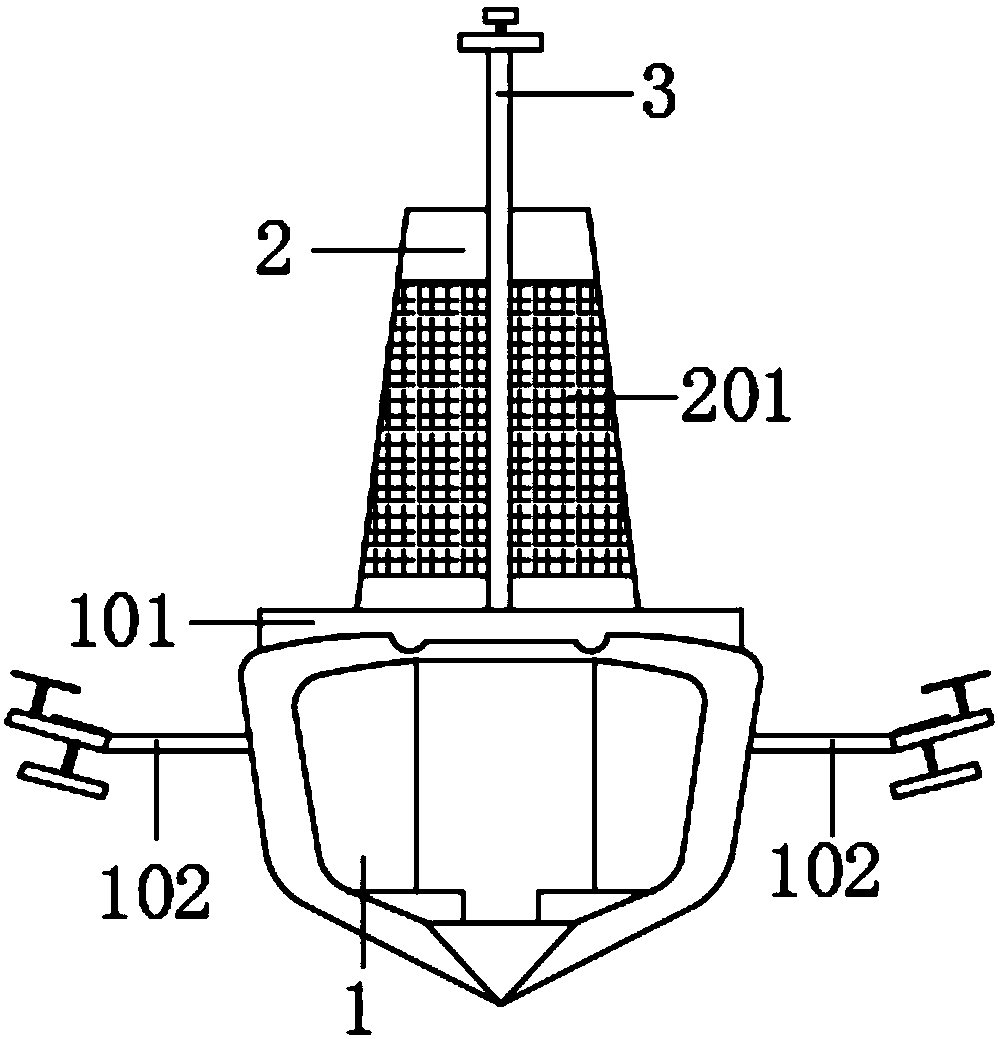

Hydrological floating body stability experiment device

The invention provides a hydrological floating body stability experiment device, comprising a first V-shaped experiment plate, a camera, a first contact sheet, a second contact sheet and indicator lights; a solar photovoltaic power generation set is embedded in an outer side of a triangular tapered structure; a fixing plate is fixed on front ends of the first V-shaped experiment plate, a second V-shaped experiment plate and a third V-shaped experiment plate through a support rod; sliding rods on sliding floating bodies run through corresponding experiment plates before being connected to a bottom part of a sliding plate. The first contact sheet is mounted on one end of a top part of the sliding plate, and the second contact sheet is mounted on an end of a top part of the fixing plate. Thesliding floating bodies on the front ends of the V-shaped experiment plates contact with a water surface, and the first contact sheet and the second contact sheet on the fixed plate are enabled to bein contact with each other; the indicator lights, a timer and a storage battery form a closed loop; oscillating degrees can be indicated via the indicator lights corresponding to different experimentplates, and oscillating time can be recorded via the timer so to test stability of the floating bodies.

Owner:倪秋杰

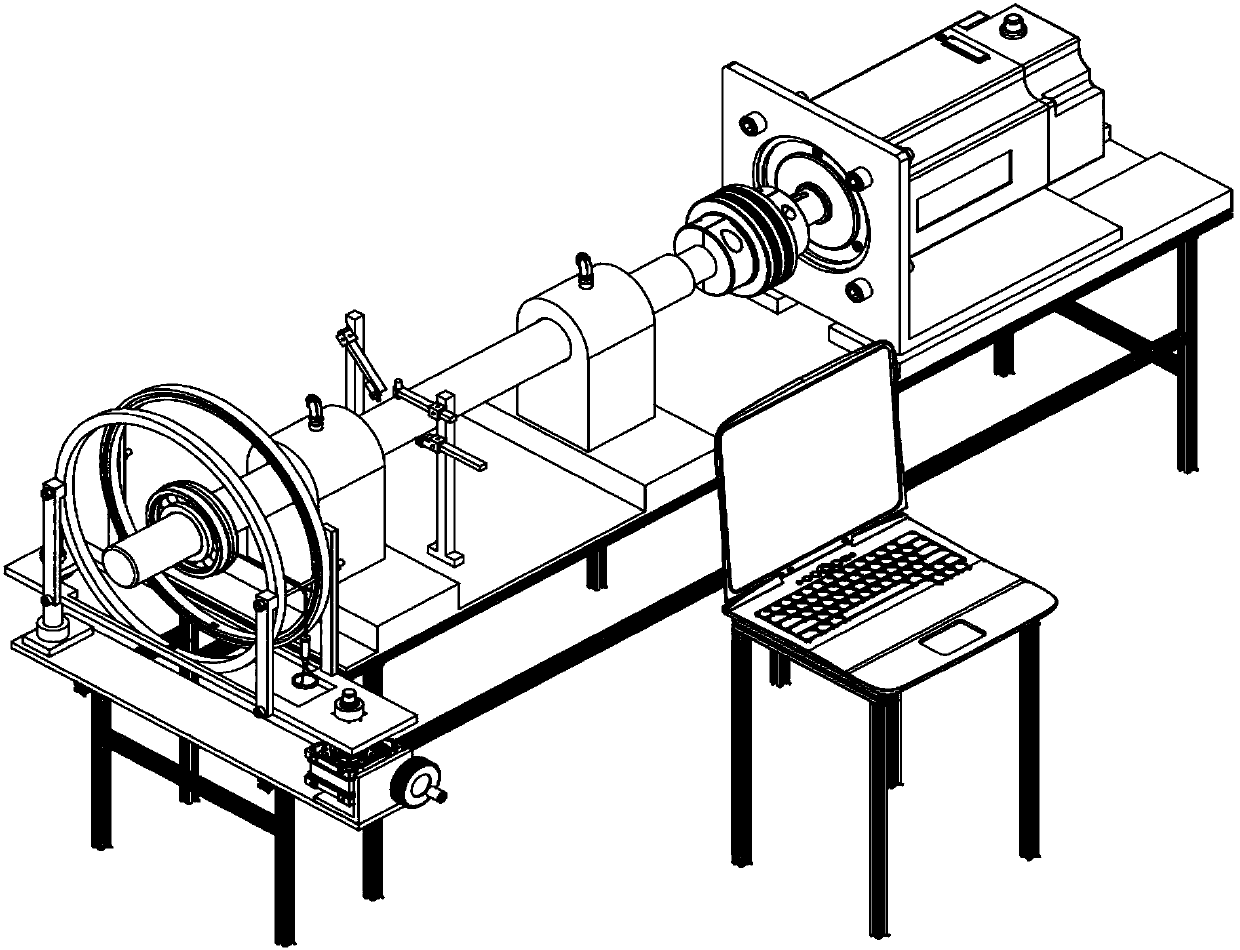

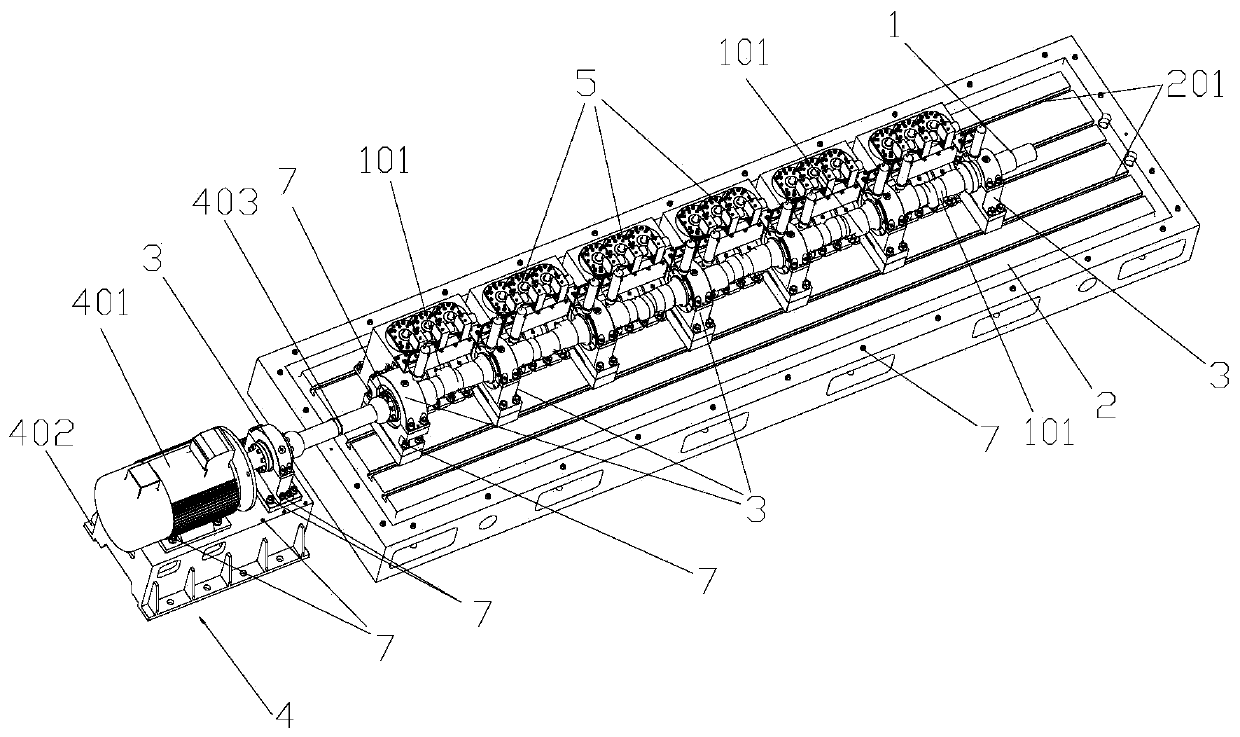

Test device for radial static pressure gas bearing experiment

The invention designs a test device for a radial static pressure gas bearing experiment. The test device mainly consists of a spindle system module and a loading mechanism module. The spindle system module includes a computer table, a computer, a rack, a driving motor, a coupling, radial static pressure gas bearings, a spindle, micro displacement sensors, and micro displacement sensor brackets. The loading mechanism module includes parallel wheels, a loading bearing, a circular leather sheath, a tension rope, a bearing rod, a spring dynamometer, a weight disc, supporting frames, an upper supporting plate, a guide rail, a worm gear, a handwheel, and a lower supporting plate. The spindle in the spindle system is carried by the two radial static pressure gas bearings. Displacement detection is carried out on the spindle by the three micro displacement sensors. One end of the spindle is driven by the driving motor through the coupling, and the other end is loaded by the loading mechanism through the loading bearing. The test device for the radial static pressure gas bearing experiment can test the static stiffness and dynamic stability load of the radial static pressure gas bearings, adopts the special loading mechanism, can load the spindle from any angle in the radial direction, and can adjust the height of the loading.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for testing stability of thickened oil

The invention discloses a method for testing stability of thickened oil. The method comprises the steps of: (a) preparing a thickened oil emulsion; (b) putting the emulsion into an experimental container; (c) standing the experimental container into a constant temperature oven for a period of time; (d) recording the deposition water amount at the bottom of a measuring cylinder, dividing the deposition water amount by total moisture content in the emulsion of the thickened oil to obtain the settling dehydration rate; and (e) analyzing the stability of the thickened oil through the settling dehydration rate, and judging that the thickened oil emulsion with high settling dehydration rate is unstable. The stability of the thickened oil can be rapidly tested by the method; and the method is high in test accuracy and low in test cost, and data support is provided for mining of the thickened oil.

Owner:王兴洋

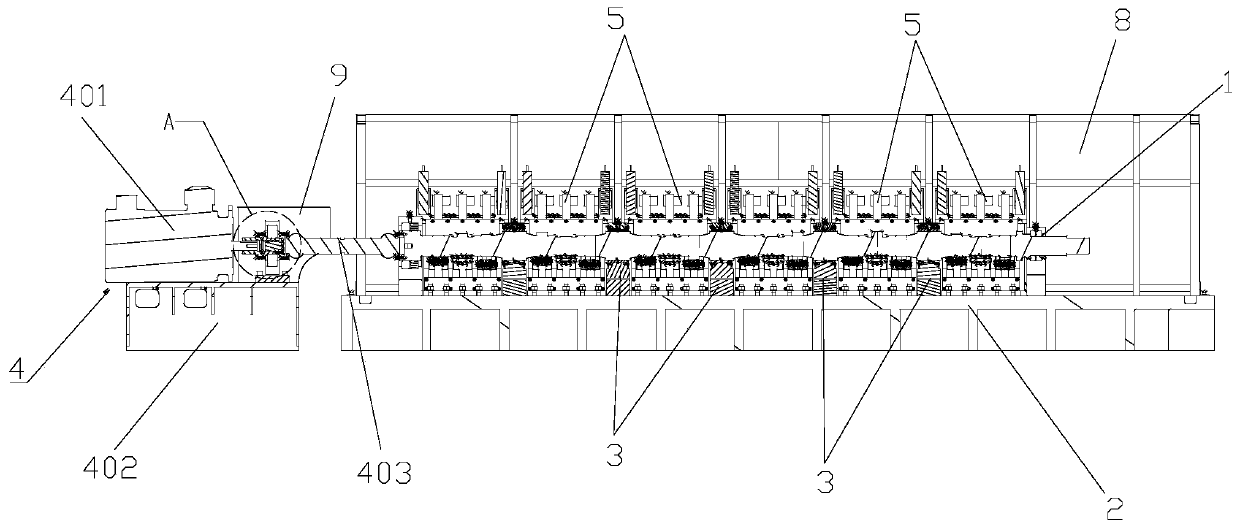

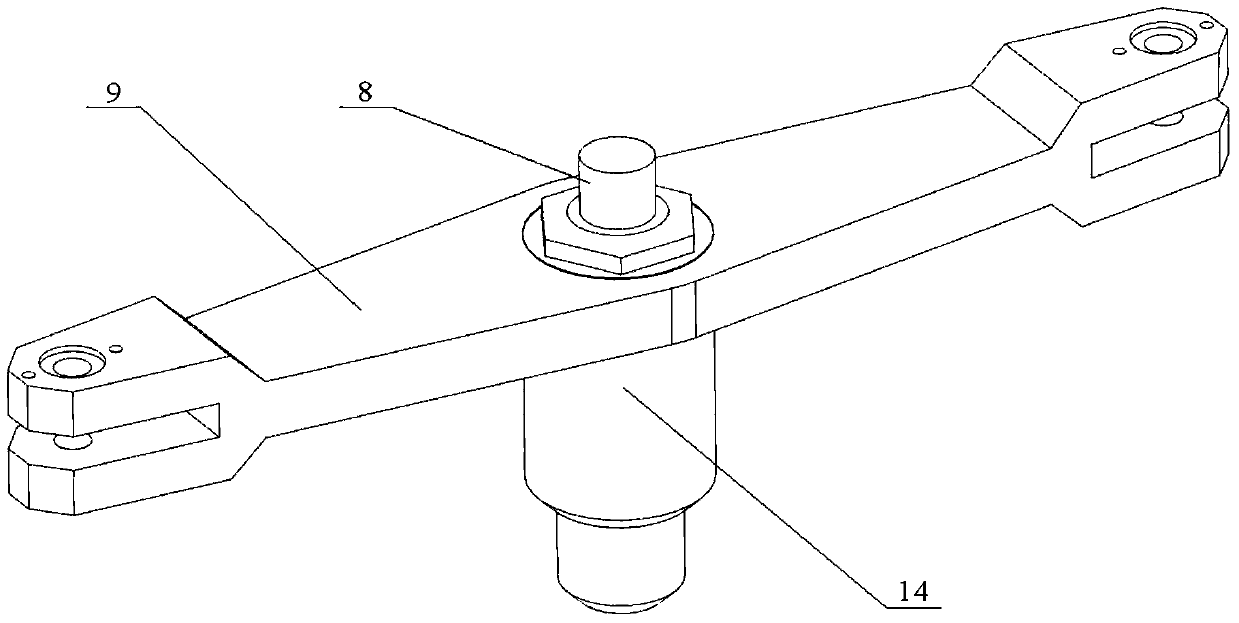

Camshaft testing equipment

The invention discloses camshaft testing equipment. The camshaft testing equipment comprises a base, loading devices arranged on the base, a supporting device for supporting a camshaft and a driving device for driving the camshaft to rotate; each loading device comprises a support, loading swing arm assemblies matched with cams arranged on the camshaft and preloading assemblies mutually cooperating with the loading swing arm assemblies; each loading swing arm assembly comprises a swing arm and a reading board perpendicularly arranged in the middle of the swing arm, rollers are arranged at thetwo ends of each swing arm, standing boards are arranged on the supports, and the middles of the swing arms are rotatably connected to the standing boards; and each preloading assembly comprises a shell, a gland located over the shell, an elastic part, an upper spring base and a lower spring base, wherein the elastic part and the upper spring base are located in the space formed between the shelland the gland,the upper end of the elastic part acts on the upper spring base, and the lower end of the elastic part acts on the lower spring base.

Owner:SUZHOU NUCLEAR POWER RES INST +2

A method for inspecting particle size distribution of pulverized coal

The invention discloses a method for inspecting the pulverized coal particle size distribution. According to the method, the pulverized coal particle size distribution is expressed by using a power function, pulverized coal which is pulverized by coal pulverizers is screened according to particle size industrial analysis, a mesh number is converted into particle diameter mu m, and the percent content of different particle diameters is measured; the measured percent content of the different particle diameters is introduced to an equation of the power function, so as to determine a and b, and then drawing is performed by using the particle diameter as an X axis and the mass fraction as a Y axis, so that whether the particle size of the pulverized coal which is pulverized by the coal pulverizers is stable can be determined according to the relationship between a and b. According to the method for inspecting the pulverized coal particle size distribution, a and b values in the corresponding equation of the particle size distribution are different for different coal pulverizers, but a certain function relationship exists, and whether the a and b values which are calculated according to products pulverized by the coal pulverizers conform to the function relationship is determined, so as to express the pulverized coal particle size and determine the stability of the pulverized coal which is pulverized by the coal pulverizers.

Owner:CHINA UNIV OF MINING & TECH YINCHUAN COLLEGE +1

A Constant Linear Load Simulator

The invention belongs to the technical field of steering engines, and particularly relates to a constant linear load simulation device. The linear load simulation device comprises a cover plate, a screw rod rotating base, a screw rod rotating pin, a baseplate, a first locating block, a limiting block, a steering rod locating pin, a steering rod, a spring fixator, a spring, a nut, a screw rod and a tacking nut. The problem in the prior art that there is no linear force loading equipment which can be used for testing the accuracy and the degree of stability of the steering engine action in a simulation way can be solved. The characteristics that the elongation of the spiral spring is in direct proportion to the size of the tensile force, and the linear force output is stable and high in reliability are utilized, the elongation of the spring is fixed through thread self-locking, and direction change of the linear force can be guaranteed through combination of multiple single-degree-of-freedom joints so as to have force output of forward and backward directions, the linear simulation load of forward and backward directions can be provided for the linear steering engine, and testing of the accuracy and the degree of stability of the steering engine action can be met.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com