Method for detecting circulating stability of coating

A technology of cycle stability and detection method, used in measurement devices, analytical materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

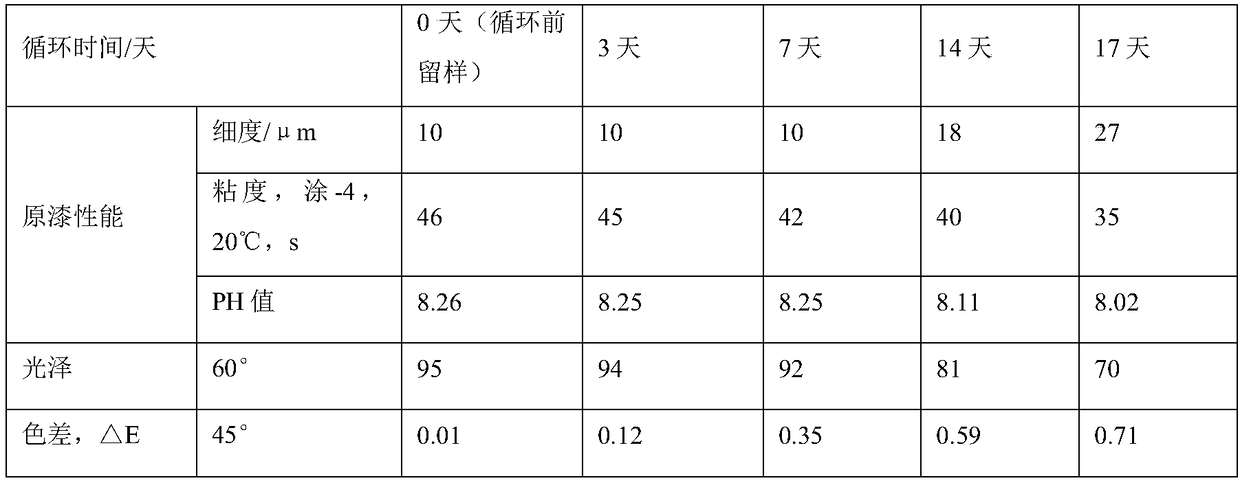

[0044] Evaluate the cycle stability of AR 2000 water-based metallic paint (flash crystal silver gray) used in a car site, test the cycle stability of the water-based silver car topcoat in the circulating pump of the car painting site, and when there is an abnormality, the possible Analyze the reasons:

[0045] Test according to the detection method of coating cycle stability of the present invention:

[0046] 1. Take out 4kg of the paint to be tested as a comparison sample before and after the experiment;

[0047] 2. Take another 30kg of paint to be tested and put it into the paint tank of the circulation experiment;

[0048] 3. Refer to the on-site pipeline circulation conditions, set and record the circulation pump and parameters, the parameters are shown in Table 1;

[0049] 4. Detect and record the original paint parameters of the 4kg sample paint taken out;

[0050] 5. Start the circulation equipment, conduct a cycle stability experiment on the paint, take samples at t...

Embodiment 2

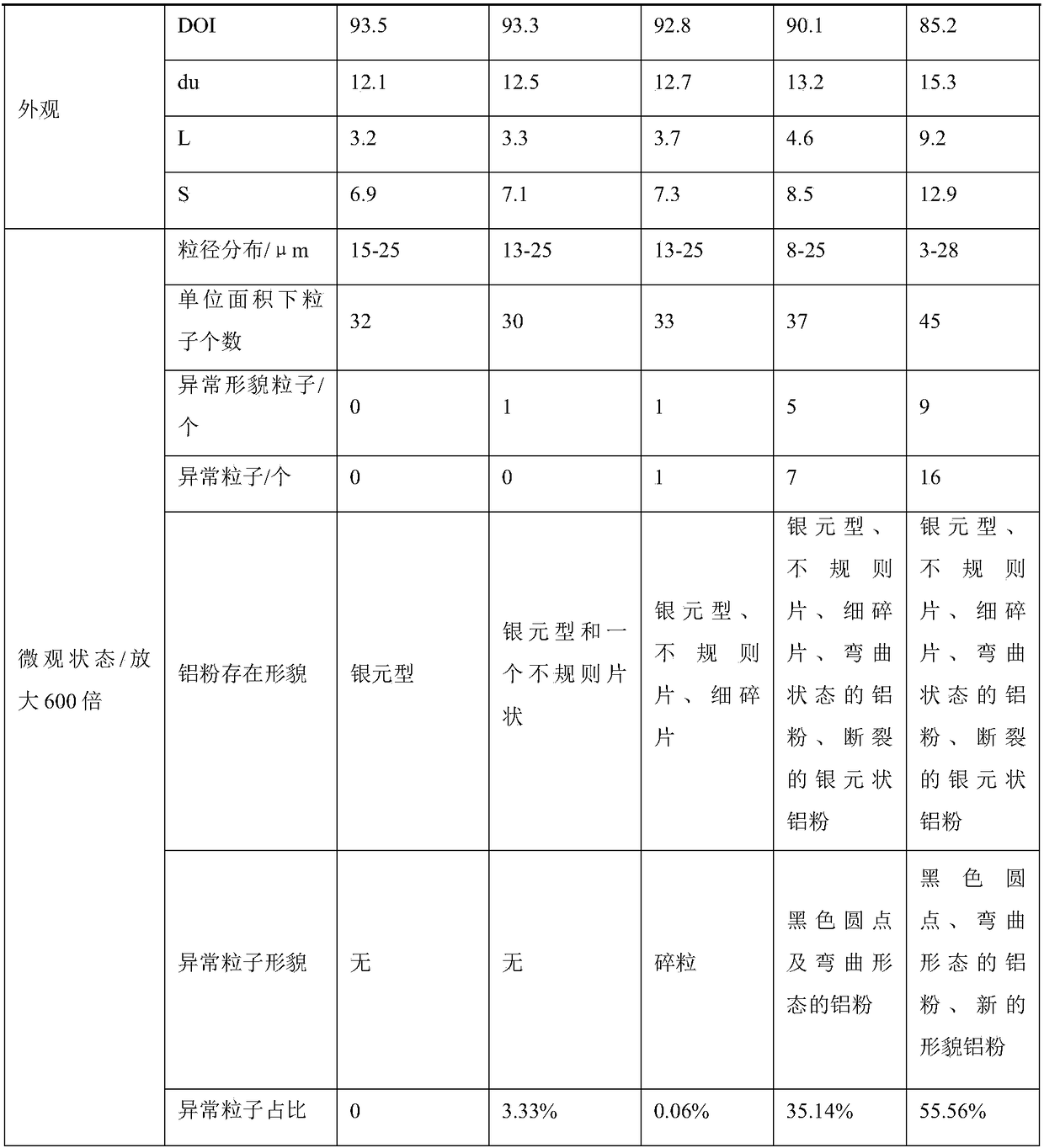

[0066] The three paints (water-based metallic paint A, B, C (A: AR 3000 Ayers Gray; B: laser gray water-based metallic finish; C: AR 20001F7)) are all metallic water-based paints, and the colors are similar, all of which are silver Gray, visually, flashing effect and appearance are equivalent, but in order to compare the workability of the paint, the cycle stability of these three paints is now compared and evaluated:

[0067] Test according to the detection method of coating cycle stability of the present invention:

[0068] 1. Take out 4kg of the prepared coatings to be tested as the comparison samples before and after the experiment;

[0069] 2. Take another 30kg of the paint to be tested and put it into the paint tank of the circulation experiment;

[0070] 3. Set the pipeline circulation conditions. The circulation equipment of the three paints is consistent, and at the same time, the parameters are also consistent. Set and record the circulation pump and parameters. The...

Embodiment 3

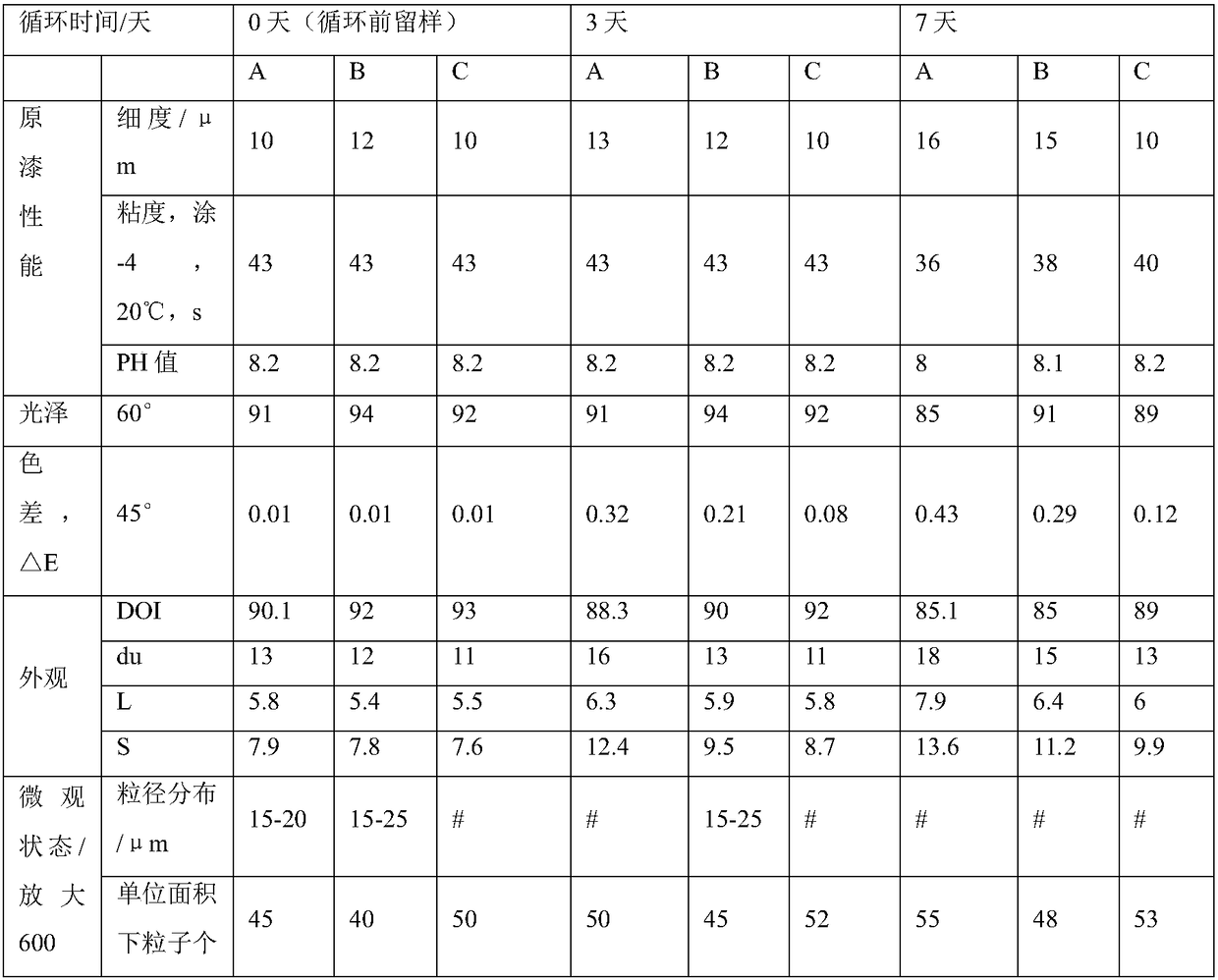

[0090] Evaluate the cycle stability of AR 2000 3R3 used in a car site, test the cycle stability of the car topcoat in the circulating pump of the car painting site, and analyze the possible causes when abnormalities occur:

[0091] Test according to the detection method of coating cycle stability of the present invention:

[0092] 1. Take out 4kg of the paint to be tested as a comparison sample before and after the experiment;

[0093] 2. Take another 30kg of paint to be tested and put it into the paint tank of the circulation experiment;

[0094] 3. Refer to the on-site pipeline circulation conditions, set and record the circulation pump and parameters, the parameters are shown in Table 6;

[0095] 4. Detect and record the original paint parameters of the 4kg sample paint taken out;

[0096] 5. Start the circulation equipment, conduct a cycle stability experiment on the paint, take samples at the preset time points on the 3rd day, 7th day, 14th day, and 17th day, and test a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com