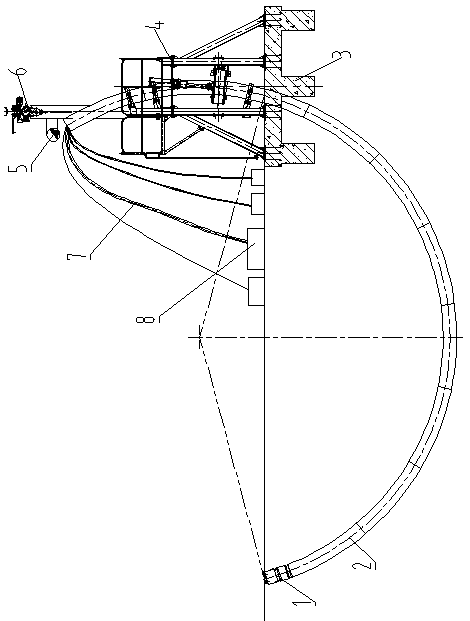

Device and method for testing curved pipe-roofing machine

The technology of a test device and a test method, which is applied in the field of the test device of the curved tube screen machine, can solve the problems of difficult attitude control, lack of theoretical and experimental basis, slag generation, etc., and achieves convenient operation, simple structure, verification of construction accuracy and reasonable design. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

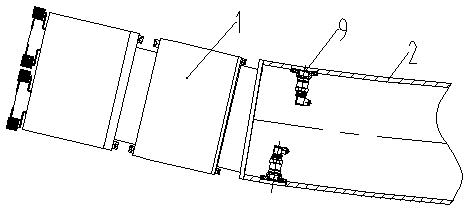

[0040] Embodiment 2, a curved pipe curtain machine test device, the steel pipe section 2 is mainly welded by several branch pipe joints, the branch pipe joints are hollow structures, and the pipe branch joints are welded to the main machine or adjacent pipe branch joints. Use docking rings for precise positioning. Two pressure detection devices 9 are arranged in the pipe branch joint connected with the main engine 1, and the two pressure detection devices 9 are respectively arranged on the upper wall and the lower wall of the pipe branch joint; they are used to detect the earth pressure of the main machine at different positions.

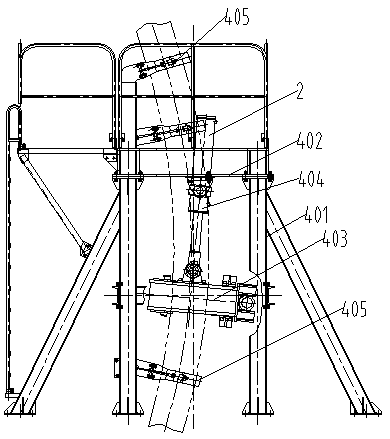

[0041] Further, the guide mechanism 5 includes a laser emitter 501, a repeater 502 and a laser receiver 503, the laser emitter 501 is arranged on the upper part of the push mechanism 4, the repeater 502 is arranged inside the branch section, and the laser receiver 503 is arranged At the tail of the host 1 , the laser transmitter 501 corresponds to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com