Dust removal and cooling device for mine

A cooling device and mine technology, applied in mine/tunnel ventilation, safety devices, dust prevention, etc., can solve the problems of water consumption, power consumption equipment, not enough environmental protection, etc. Poor cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

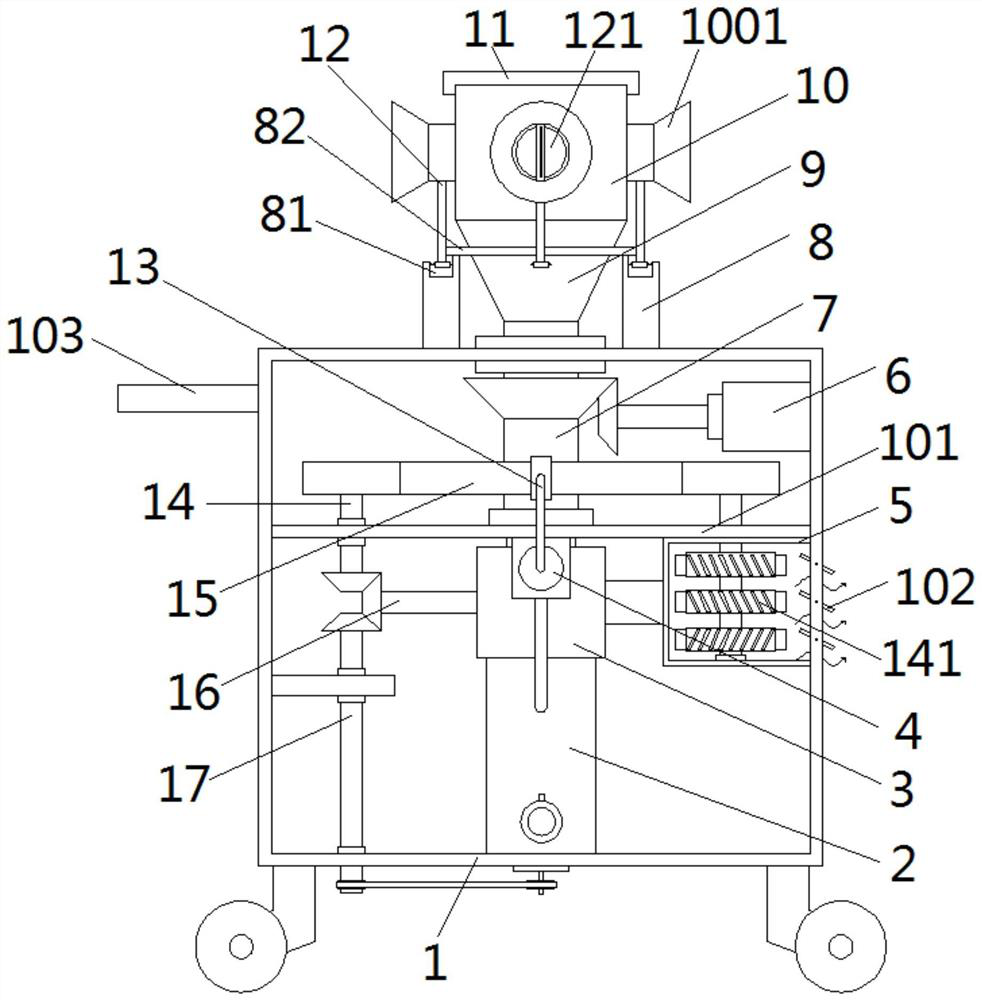

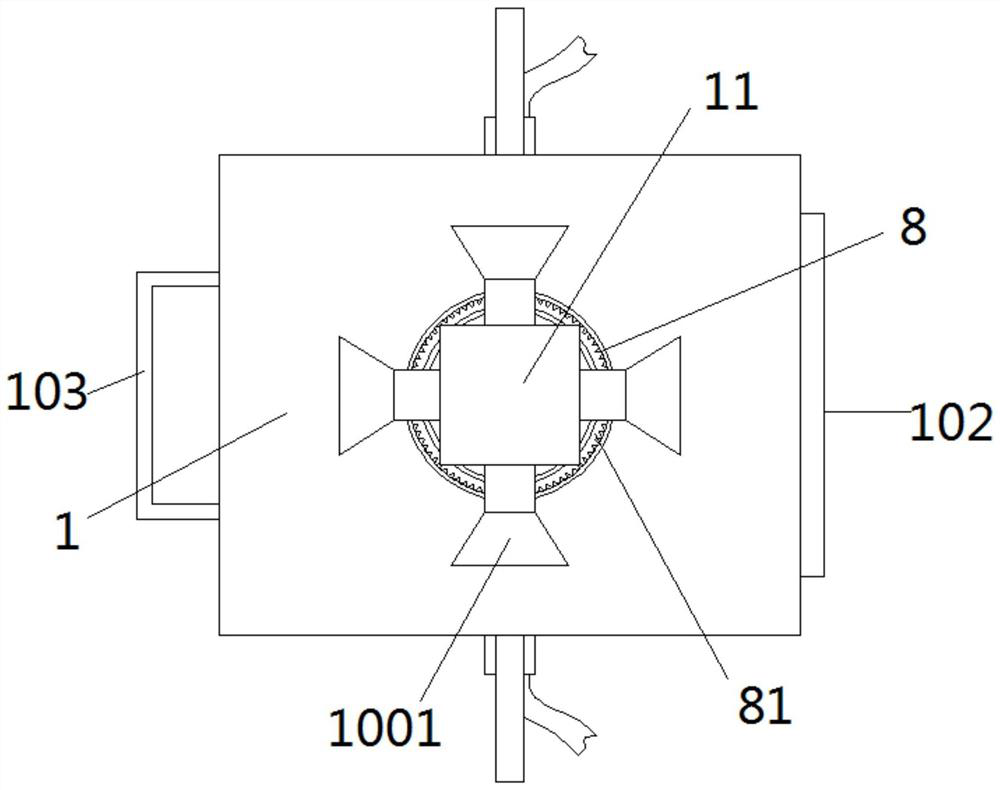

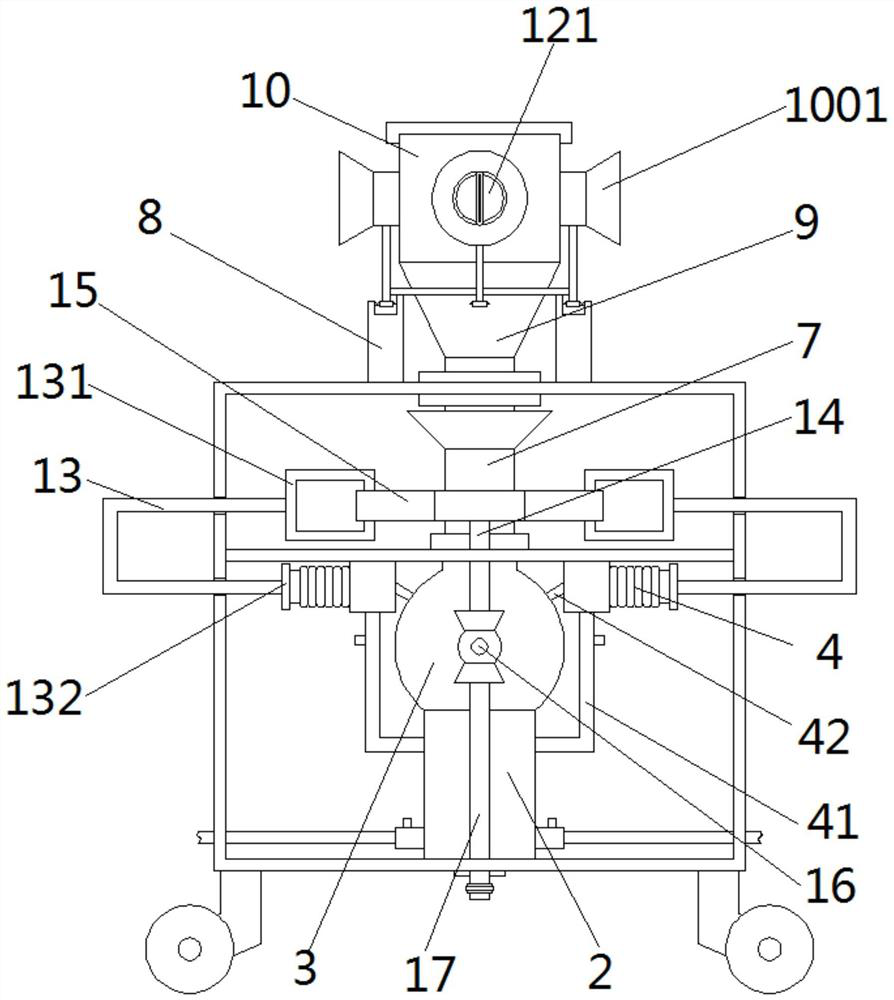

[0032] as attached figure 1 to attach Figure 7Shown: a dust removal and cooling device for mines, including a box body 1, a sedimentation pipe 2 is vertically and fixedly connected to the center of the inner bottom of the box body 1, and a dust removal box 3 is fixedly connected to the top of the sedimentation pipe 2, and the inside of the box body 1 is located The upper end of the dust removal box 3 is fixedly connected with a support plate 101, and the center of the top of the support plate 101 rotates vertically and horizontally and is connected with a connecting pipe 7. The upper end of the connecting pipe 7 is located inside the box body 1 and is fixedly connected with a bevel gear. The top of the connecting pipe 7 runs through to the box body. 1. The outer side is fixedly connected with a funnel 9, and the top of the funnel 9 is fixedly connected with a dust inlet box 10. There is an opening on the top of the dust inlet box 10, and a cover plate 11 is opened and closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com