Flexible lining plate and flexible display panel

A liner and flexible technology, applied in the display field, can solve the problems of low strength and easy breakage of flexible liners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

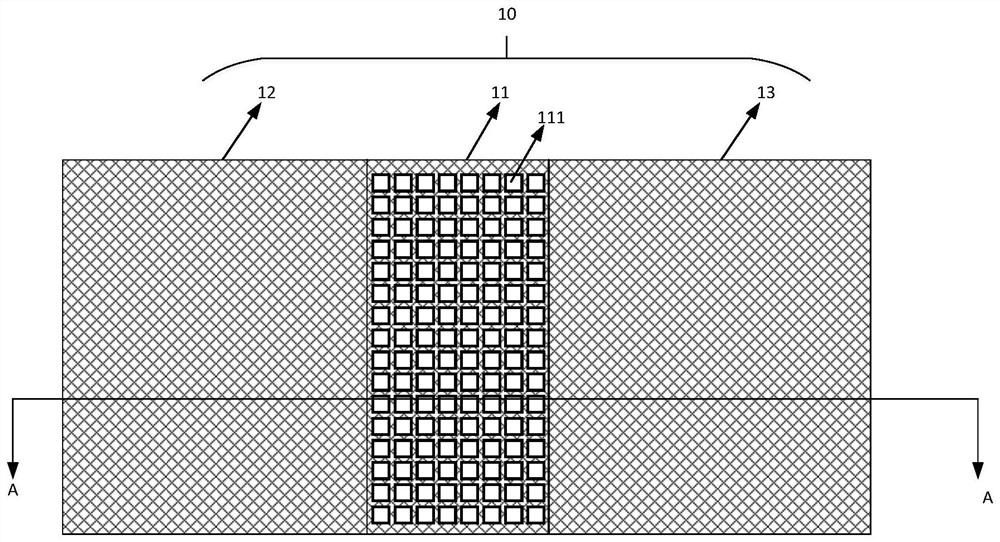

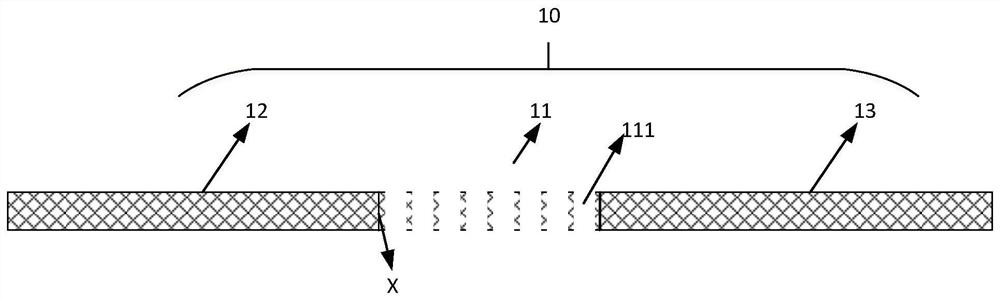

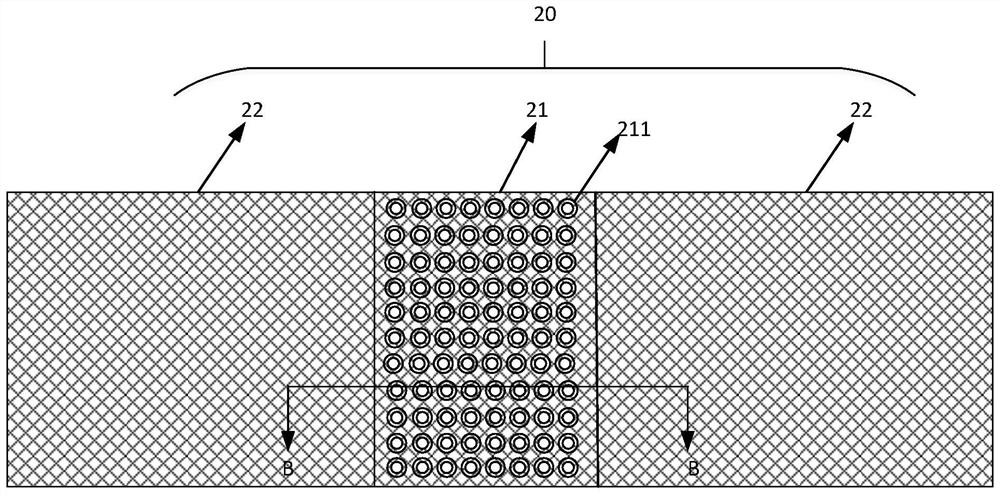

[0056] refer to image 3 , shows a schematic structural view of a flexible lining 20 provided by an embodiment of the present invention, the flexible lining 20 includes: a bending area 21 and support areas 22 on both sides of the bending area 21; refer to Figure 4 and Figure 5 ,for image 3 A cross-sectional view of the B-B direction of the middle bending area 21, wherein a plurality of hole structures 211 are arranged on the first surface a of the bending area 21; wherein, the openings of the hole structures 211 and the openings of the hole structures 211 The area of the orthographic projection of the bottom on the first surface a is different; the orthographic projection of the opening of the hole structure 211 on the second surface of the bending region includes: a first straight line; the bottom of the hole structure is at The orthographic projection of the second surface of the bending area includes: a second straight line or point shape; the length of the first str...

Embodiment 2

[0091] In the embodiment of the present invention, refer to Figure 16 , shows a schematic structural view of a flexible liner provided by an embodiment of the present invention, the shape of the cross-section of the hole structure 211 parallel to the first plane a includes: a second drop shape. refer to Figure 18-Figure 21 ,for Figure 16 In the cross-sectional view of the F-F direction, the shape of the cross-section of the hole structure 211 perpendicular to the first plane a is the second rectangle.

[0092] refer to Figure 16 and Figure 18 , when the shape of the cross-section of the hole structure 211 parallel to the first plane a includes: the second drop shape, the hole structure 211 may be a hole structure with the same depth, refer to Figure 19 , can also be a through-hole; refer to Figure 20 and Figure 21 , it can also be a transition from a through hole in the middle area to a hole structure on both sides; wherein, from the middle area of the bending ...

Embodiment 3

[0102] refer to Figure 19-Figure 21 , which shows that an embodiment of the present invention provides a flexible display panel, including the flexible liner 20 described in any one of the above.

[0103] Wherein, the flexible display panel further includes: a first adhesive material layer 30 ; a display function layer 40 ; a second adhesive material layer 50 and a cover plate 60 . Wherein, R is the bending radius of the flexible display panel.

[0104] refer to Figure 23 , which is a U-shaped inward folding of the flexible display panel. refer to Figure 24 , which is a U-shaped outward folding of the flexible display panel; refer to Figure 25 , the flexible display panel is inwardly folded in a drop shape.

[0105] In the embodiment of the present invention, refer to Figure 25 , two blank areas can be set in the bending area of the flexible display panel, and the blank area does not need to be bent when the water-drop shape is folded inwardly, therefore, the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com