Waste HMX and TNT mixed explosive recovery method

A technology of Otti explosives and recovery method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as incomplete separation, and achieve the effects of improving safety, improving performance and avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

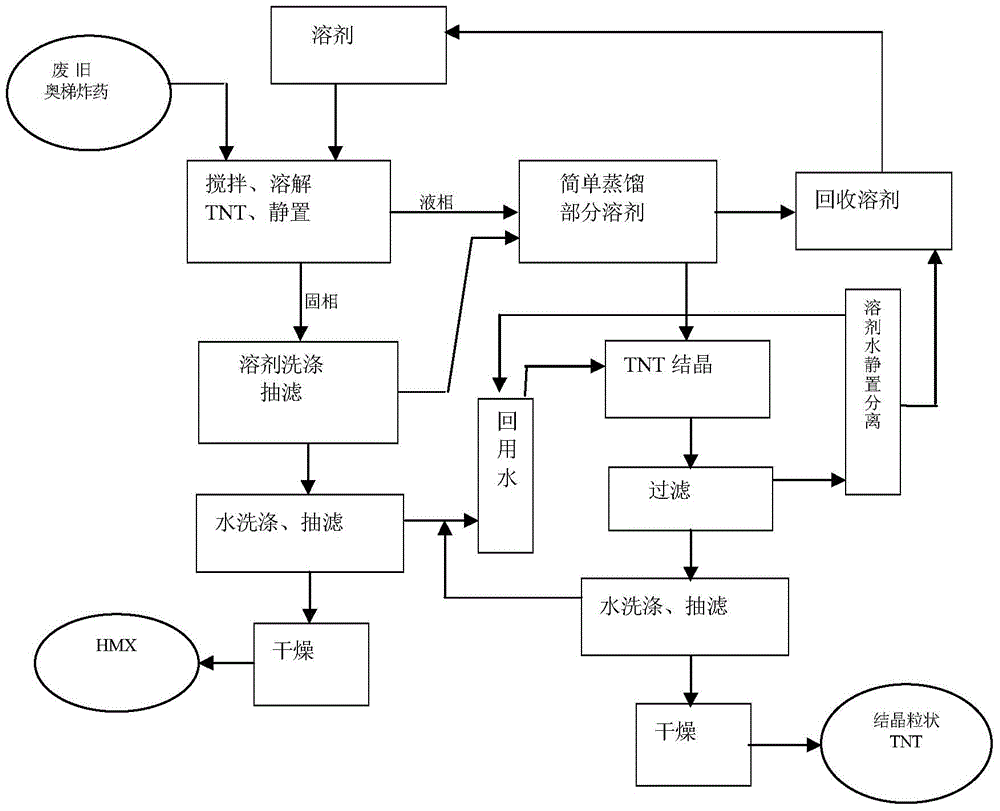

[0046] figure 1 It is intended to illustrate the method in detail, not to limit the scope of the present invention.

[0047]Taking HMX / TNT 70 / 30 waste Otti explosives as an example to recycle them on two 300L jacketed heat exchange reactors and some necessary supporting equipment platforms.

[0048] The TNT in the spent Otti explosives was dissolved in the excess of solvent benzene, and then the solid-phase-HMX and liquid-phase-benzene-unsaturated solutions of TNT were separated. The solid phase is washed with benzene, suction filtered, and then washed with water, suction filtered, and dried to obtain the HMX product; the liquid phase and the above-mentioned benzene washing mother liquor are firstly distilled off part of the benzene by simple distillation, and then the crystallization method is combined by cooling and adding water. , crystallize TNT, and then filter, wash with water, filter with suction, and dry to obtain crystalline granular TNT products.

[0049] The speci...

Embodiment 2

[0060] Taking HMX / TNT 70 / 30 waste Otti explosives as an example to recycle them on two 300L jacketed heat exchange reactors and some necessary supporting equipment platforms.

[0061] Using xylene as a solvent, the TNT in the spent Otti explosives was dissolved under the condition of excessive xylene, and then the solid-phase-HMX and liquid-phase-TNT unsaturated xylene solutions were separated. The solid phase is washed with xylene, suction filtered, then washed with water, suction filtered, and dried to obtain the HMX product; the liquid phase and the above-mentioned xylene washing mother liquor are firstly distilled out part of xylene by simple distillation, and then combined by cooling and adding water In the crystallization method, the TNT crystals are precipitated, and then filtered, washed with water, suction filtered, and dried to obtain a crystalline granular TNT product.

[0062] The specific process and operation steps are briefly described as follows:

[0063] 1) A...

Embodiment 3

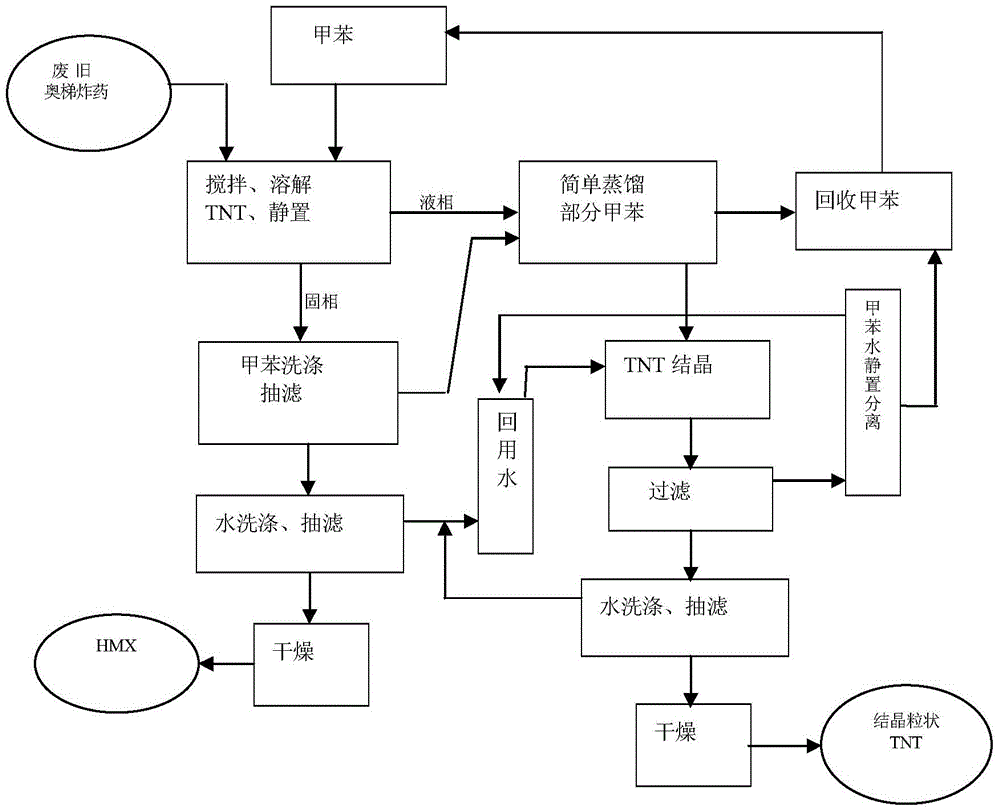

[0073] figure 1 , image 3 It is intended to illustrate the method in detail, not to limit the scope of the present invention.

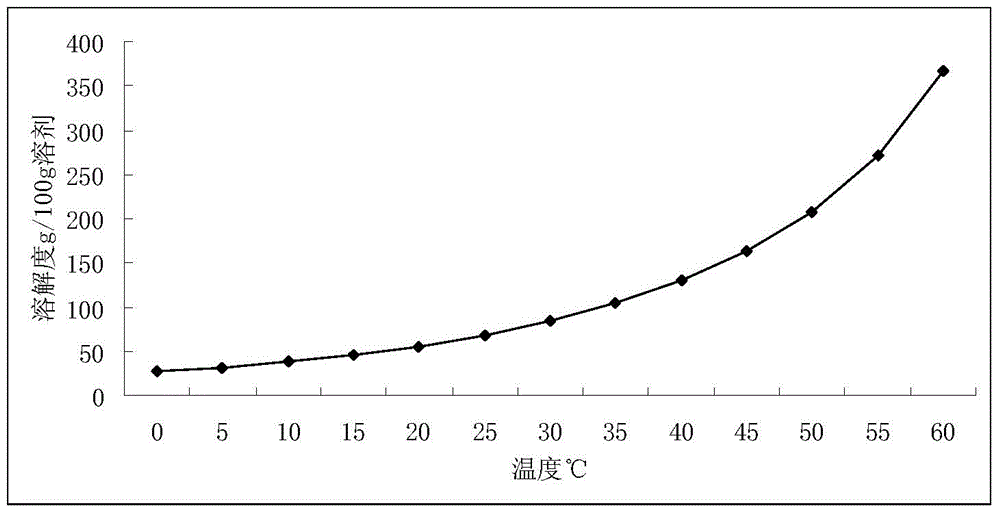

[0074] The solubility of HMX in toluene is very small (almost insoluble), while TNT is easily soluble in toluene. The solubility data of TNT in toluene is shown in the figure. figure 1 . From image 3 It can be seen that the solubility of TNT in toluene is very large, and the purpose of separation is achieved by utilizing the contrast of the solubility of the two components in the same solvent.

[0075] Taking HMX / TNT 70 / 30 waste Otti explosives as an example to recycle them on two 300L jacketed heat exchange reactors and some necessary supporting equipment platforms.

[0076] Using toluene as a solvent, the TNT in the waste Otti explosive was dissolved under the condition of excessive toluene, and then the solid phase-HMX and the liquid phase-TNT unsaturated solution of toluene were separated. The solid phase is washed with toluene, suction fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com