Containing-type node

An inclusive, node-based technology, applied in the connection of rods, connecting components, mechanical equipment, etc., can solve problems such as long-term failure, node cracking, etc., and achieve the effects of reasonable force flow transmission, reduced internal stress, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

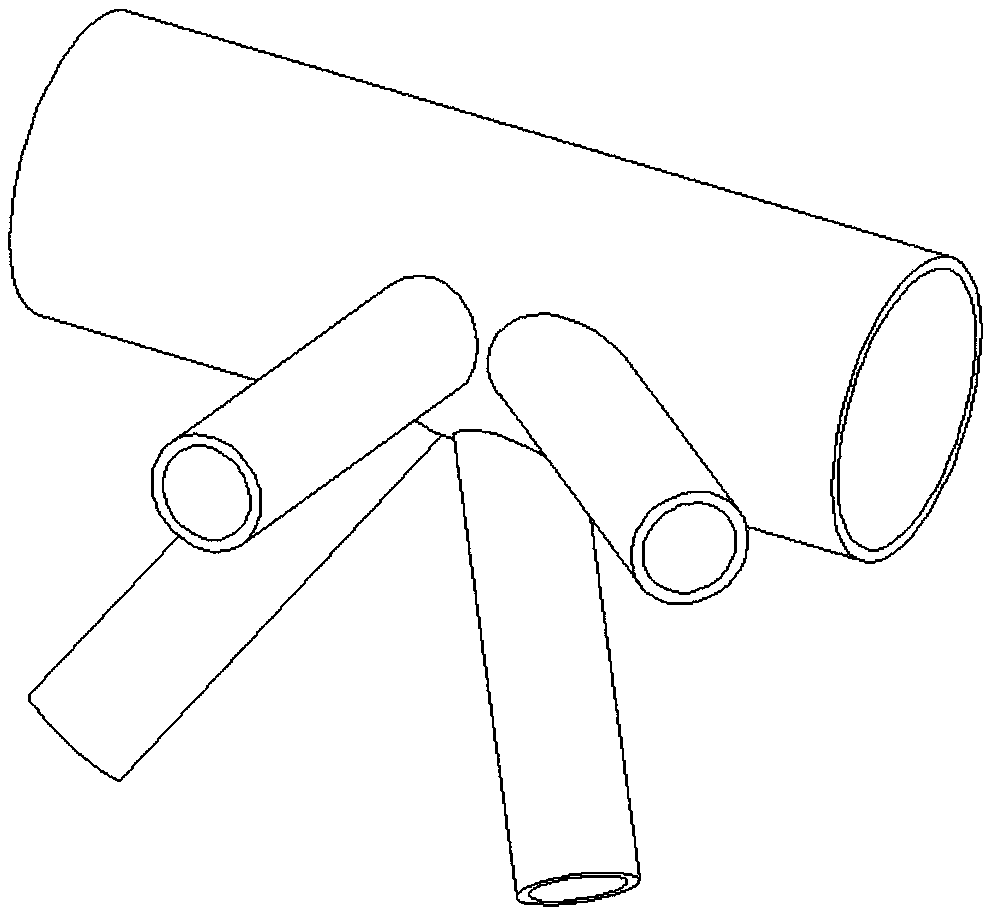

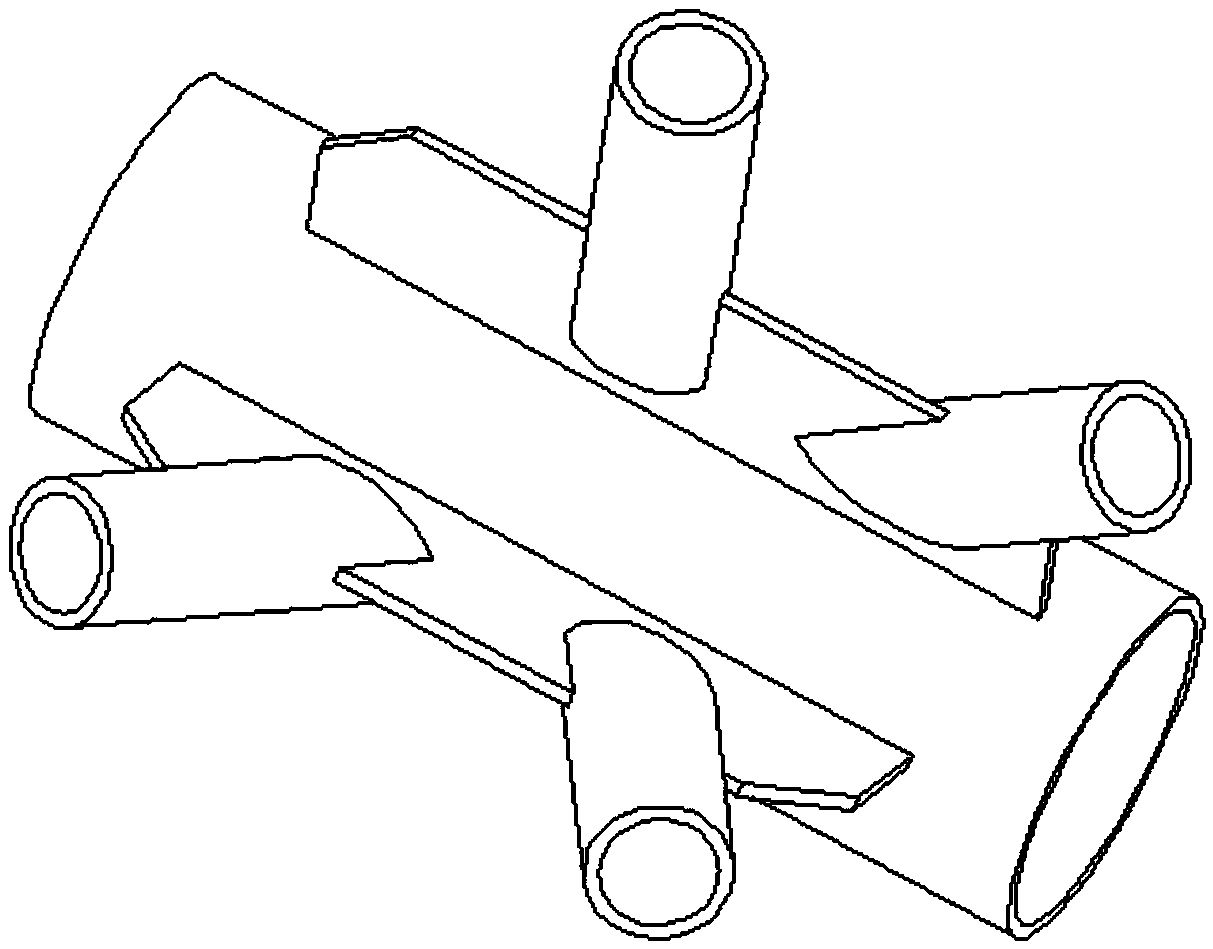

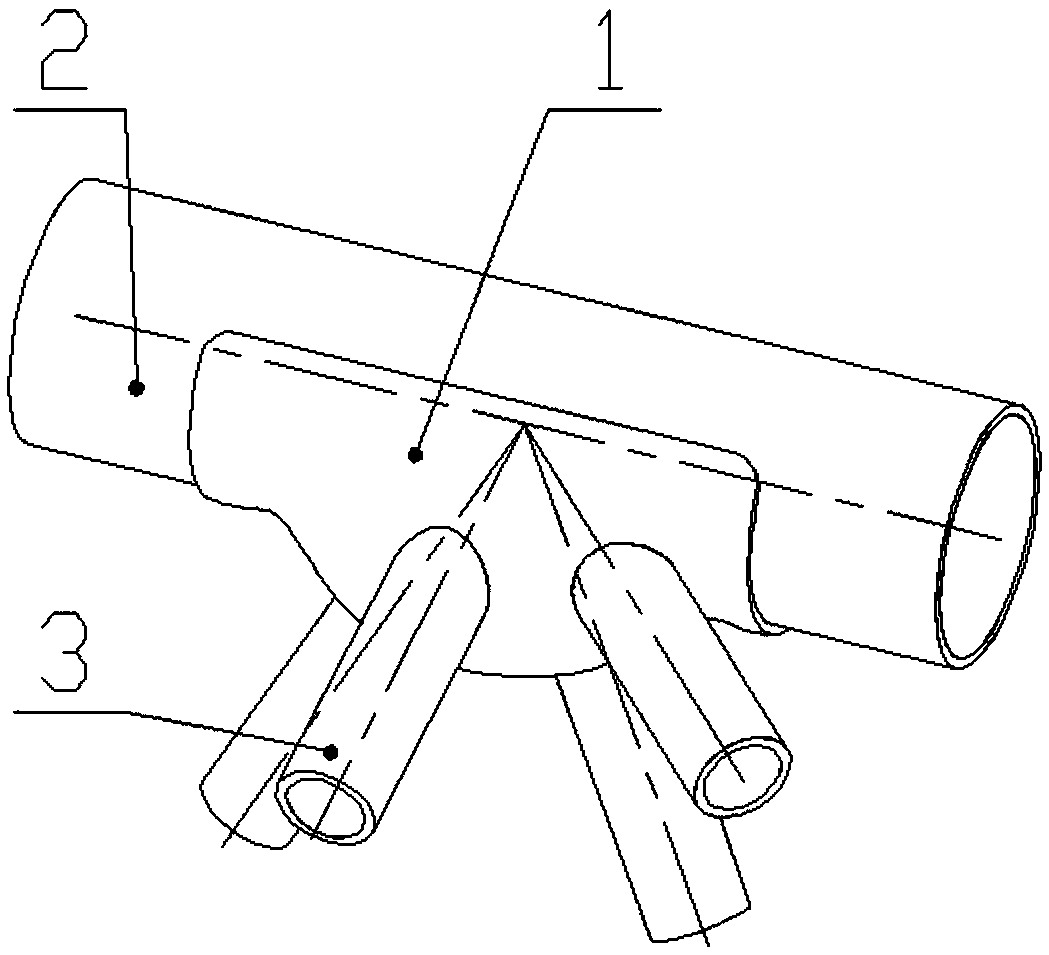

[0024] The present invention proposes an inclusive joint, which includes a curved plate for connecting the main chord and the web of the pipe structure truss, the main chord part and the web part connected with the curved plate, and the main chord part And the web part is the part of the tube structure truss that is close to the curved plate and belongs to the contained node. image 3 Shown is the structural diagram of the contained joint, where 1 is the curved plate, 2 is the main chord part, and 3 is the web part; Figure 4 is the front view of the curved slab in the contained joint; Figure 4a , Figure 4b , Figure 4c and Figure 4d respectively Figure 4 Cross-sections of the curved plate at A-A, B-B, C-C, and D-D.

[0025] The above-mentioned curved plate 1 includes an edge portion and a protrusion protruding from the edge portion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com