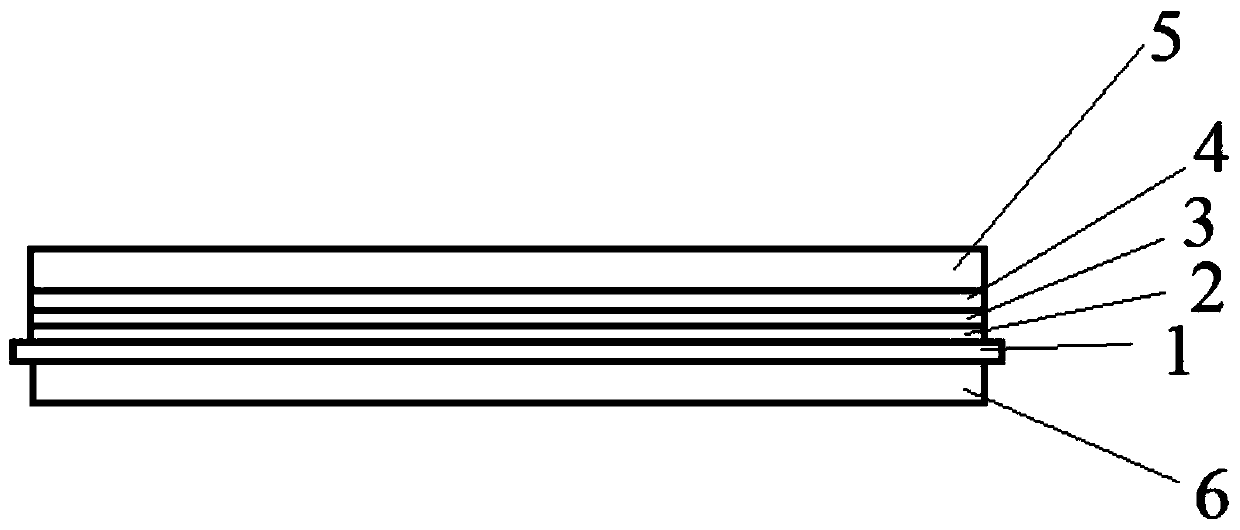

Foldable flexible cover plate and manufacturing method thereof

A flexible cover, disposable technology, applied in the direction of instruments, identification devices, etc., can solve problems such as unfavorable bending of flexible display screens, inability to protect the display screen, and easy scratching of plastic covers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] An ultra-thin glass substrate with a thickness of 40 μm is provided, and the ultra-thin glass substrate is pre-cleaned, dried and pre-treated by plasma bombardment to clean one side of the ultra-thin glass substrate.

[0089] Deposition of SiO on pretreated ultra-thin glass substrates by magnetron sputtering 2 The thin film forms an adhesion-enhancing coating, specifically using a Si target in Ar+O 2 Deposition of SiO in atmospheric environment 2 film, where Ar:O 2 The volume ratio is 1:1, the deposition atmosphere pressure is 0.3Pa-1.5Pa, and the thickness of the formed adhesion-enhancing coating is 40nm.

[0090] A mixture of transparent polyamic acid and KH550 is coated on the surface of the adhesion-enhancing coating at one time, wherein polyamic acid is added to dimethylacetamide (DMAC) solvent to form a mixed solution, and KH550 is then added to the mixed solution. Wherein the polyamic acid solid content accounts for 6wt% of the final solution, and KH550 is 5wt...

Embodiment 2-5

[0095] Examples 2-5 adopt a similar preparation method as Example 1, except that the thickness of the adhesion-enhancing coating is 10 nm, 100 nm, 200 nm, and 500 nm, respectively, and the foldable flexible cover plates of Examples 2-5 are prepared.

[0096] The foldable flexible cover of Examples 1-5 is tested in the following two aspects: 1) Hundred-grid test: that is, use a hundred-grid knife to directly scratch the foldable flexible cover, and then use adhesive tape to bond and tear the film. The adhesion performance is evaluated by the release of the film after tearing off the film. Specifically, the B value is used to express the result. The larger the B value, the better the adhesion performance; 2) Bending performance test: 90mm*60mm passing edges are provided The processed and strengthened foldable flexible cover plate is subjected to a bending test, and the transmittance ΔT at the bending place is measured after bending for the same number of times. The smaller the ΔT...

Embodiment 2

[0099] Example 2: Between 4B-5B, there is a slight release on the edge of the grid; ΔT=1.8%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com