Transformer internal fault monitoring system and control method thereof

A technology for internal faults and monitoring systems, applied in transformer/inductor components, transformer/inductor cooling, electrical component structure associations, etc., can solve problems such as crowding, transformer oil reduction, transformer failure, etc., and achieve convenient and simple use , good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

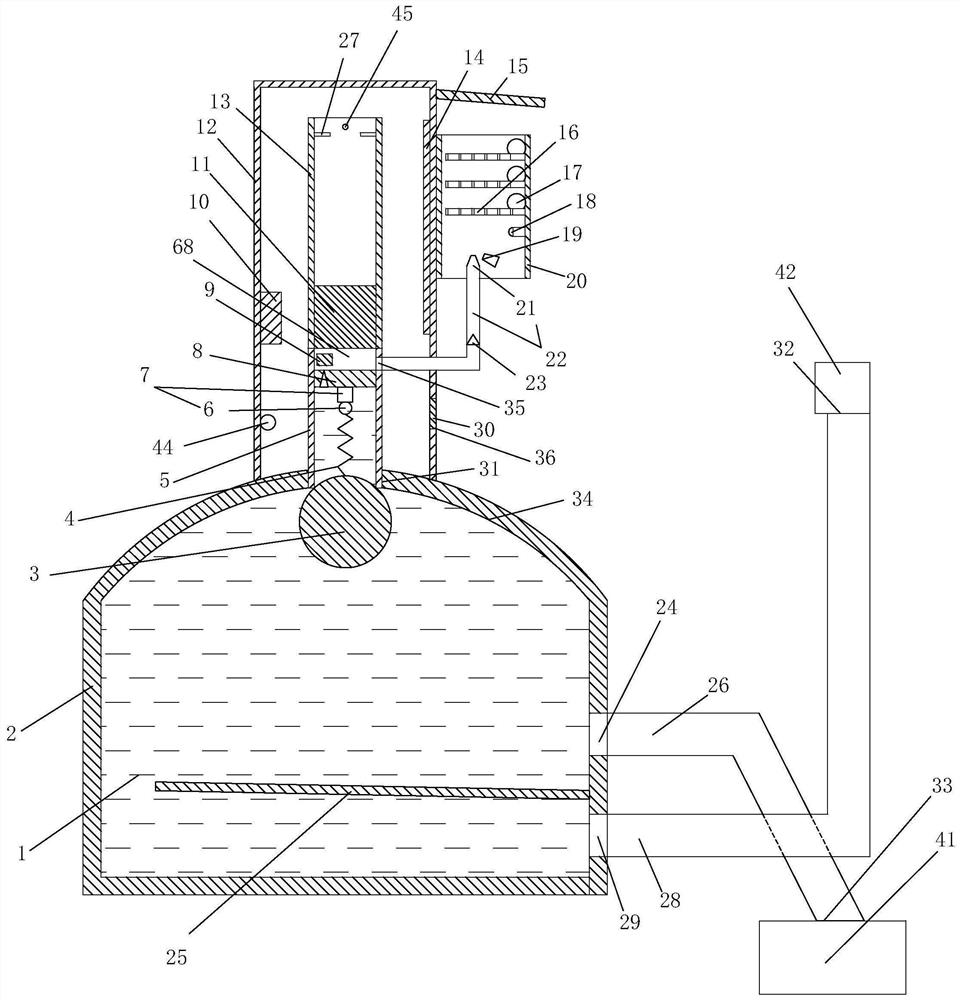

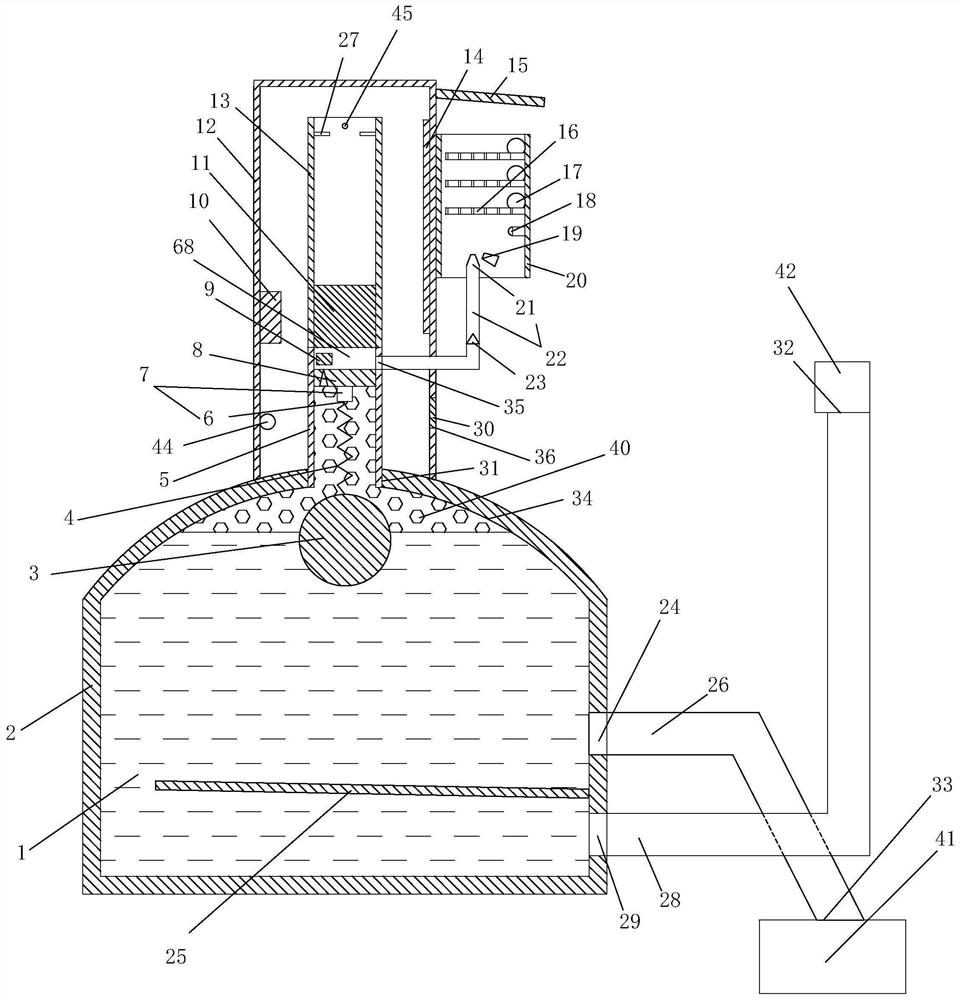

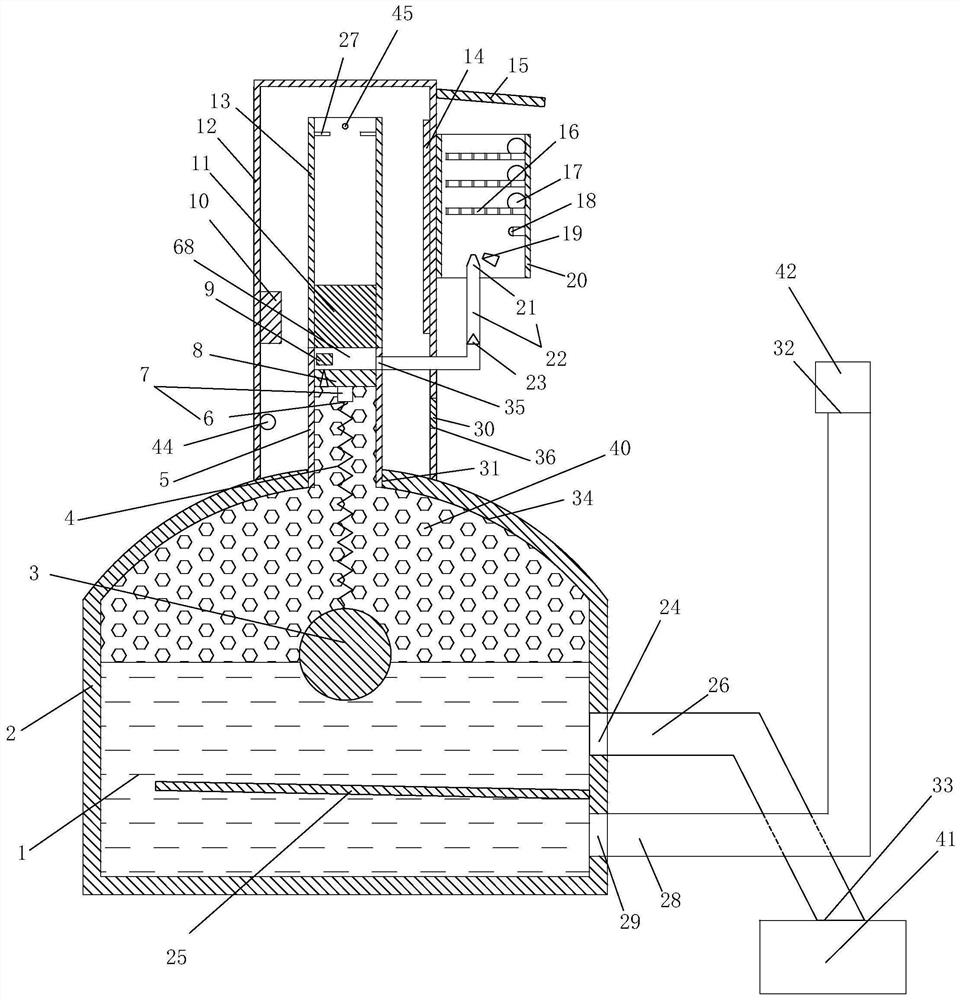

[0105] Embodiment, transformer internal fault monitoring system, see Figure 1-Figure 11 As shown, it includes a transformer oil conservator 42, a transformer oil tank 41, a transformer component 74 sealed in the transformer tank, and a power input column 71 and a power output column 75 arranged opposite to each other at the lower ends of the upper end of the transformer component respectively. The lower end of the power input column and the lower end of the power output column are sealed in the transformer oil tank; it also includes a transformer fault monitoring platform 43, a controller 39, a gas collection fault detection trigger mechanism 79, a gas color observation mechanism 97, a gas odor detection mechanism 98, Gas volume detection mechanism 99, gas flammability detection mechanism 100, bubble horizontal coordinate positioning detection mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com