Lifting cylinder head assemblies for isostatic presses

A technology of isostatic press and cylinder head, which is applied in presses, manufacturing tools, etc., can solve the problems of cylinder head falling directly, double-ended studs are easy to bend or even exercise, and cylinder head cannot be aligned automatically, so as to avoid The effect of bending or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

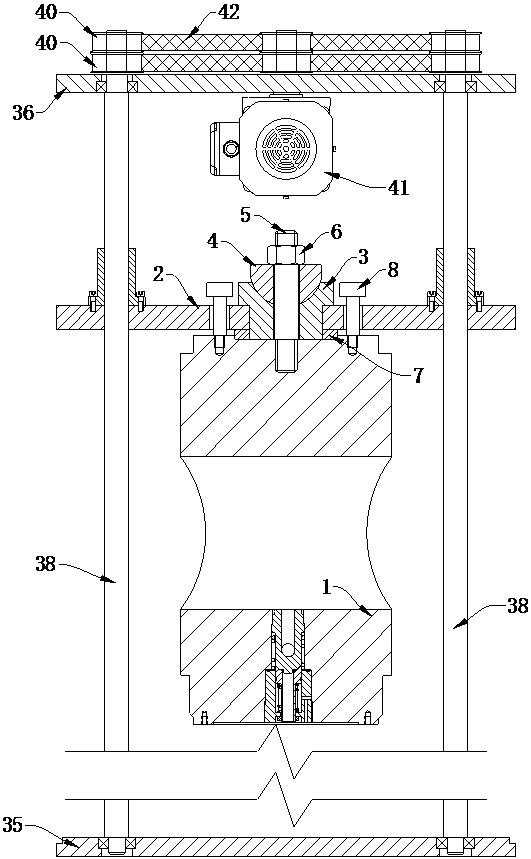

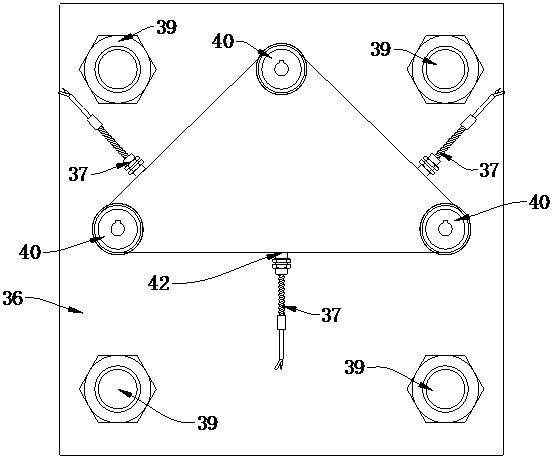

[0031] The present invention will be briefly introduced, and the description of the present invention will be briefly introduced, which will be briefly described in connection with the accompanying drawings and examples or prior art descriptions, which will be apparent from the description of the drawings. Some embodiments of the invention, for those skilled in the art, other drawings can be obtained in accordance with these drawings without paying creative labor.

[0032] The technical solutions provided in the present invention will be described in detail below with reference to the drawings. It should be noted herein to help understand the invention, but is not intended to be limited to the present invention.

[0033] In some examples, since some embodiments belong to existing or conventional techniques, there is no description thereof or not described.

[0034] In this paper, the serial number of the component itself, such as "first", "second", etc., only for distinguishing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com