Railway roadbed assembly type cable trough

A railway subgrade and cable trough technology, applied in the direction of electrical components, etc., can solve the problem that the cable trough cannot adapt to the change of the direction of the railway line and the need to avoid obstacles, and cannot adapt to the continuous change of the lateral pressure of the soil on both sides of the trough. Maintenance Overhaul difficulties and other problems, to reduce transportation and installation costs, improve environmental adaptability, and low maintenance and overhaul costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

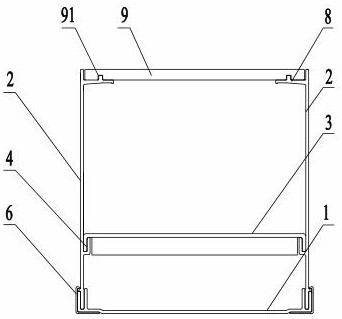

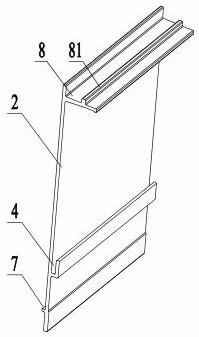

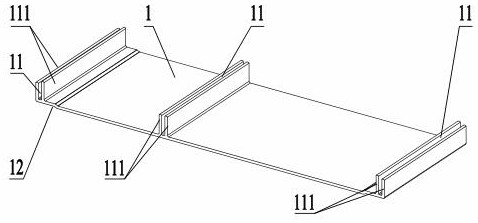

[0043] Such as Figure 1-Figure 13 As shown, a railway subgrade assembled cable trough includes trough body segments, each of which includes a bottom plate 1, two side plates 2 and a number of cross arms 3, and the inner walls of the side plates 2 are provided with clips Buckle groove 4, the bottom plate 1 is provided with a card slot 11, the side plate 2 is connected with the bottom plate 1 through the card slot 11, and the cross arm 3 is locked with the side plate 2 through the buckle groove 4 buckle connection.

[0044] In this embodiment of a railway embankment assembly type cable trough, a card slot 11 is provided on the bottom plate 1 corresponding to the position of the side plate 2. The card slot 11 includes two vertically parallel vertical plates 111, and the side plate 2 can extend into the two vertical plates. In the gap between the plates 111, the buckle connection between the side plate 2 and the bottom plate 1 is realized, and the inner wall of the side plate 2 ...

Embodiment 2

[0052] Such as Figure 1-Figure 13 As shown, the railway subgrade assembled cable trough of this embodiment has the same structure as that of Embodiment 1, except that the adjacent cover plates 9 are buckled and connected.

[0053] In this embodiment of a railway subgrade assembled cable trough, the top surface of the cover plate 9 is provided with a connection groove 1 92 along the transverse direction of the cable trough, and the bottom surface of the cover plate 9 is provided with a connection trough 2 93 along the transverse direction of the cable trough. The first connection groove 92 and the second connection groove 93 of the provided cover plate 9 are snap-connected, so as to realize the snap-fit connection of adjacent cover plates 9 .

[0054] Specifically, on the same cover plate 9, the first connecting groove 92 and the second connecting groove 93 are sequentially arranged along the traveling direction of the train, and the first connecting groove 92 and the second...

Embodiment 3

[0058] Such as Figure 1-Figure 13 As shown, a railway subgrade assembly type cable trough of this embodiment has the same structure as that of embodiment 2, the difference is that the buckle groove 4 is continuously arranged along the extending direction of the cable trough, and the side plate 2 is provided with a The buckle slot 4 is described above.

[0059] In this embodiment of an assembled cable trough for a railway subgrade, the buckle trough 4 is formed by the inner wall of the side plate 2 continuously protruding into the cable trough and extending upward, which can strengthen the side plate 2 and can be installed on the side according to the actual situation. A plurality of buckle grooves 4 are arranged parallel to the inner wall of the plate 2, which reserves a place for installing the cross arm 3, and improves the compressive strength of the side plate 2 itself. At the same time, because the buckle grooves 4 are continuously arranged, it can Slide the cross arm 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com