Solid-phase fermentation equipment for mixing kitchen waste

A technology for solid-phase fermentation and kitchen waste, which is applied in the direction of removal of solid waste, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of covering of kitchen waste, difficulty of complete fermentation of garbage, and starch soaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

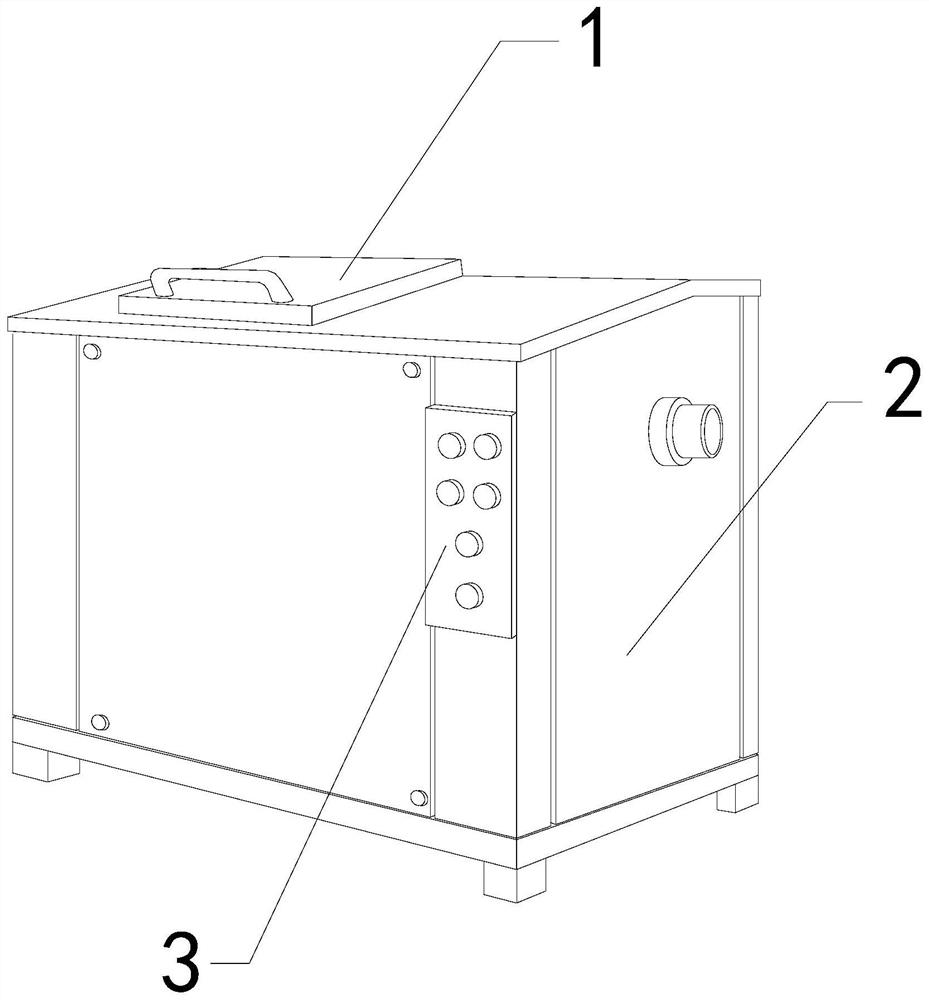

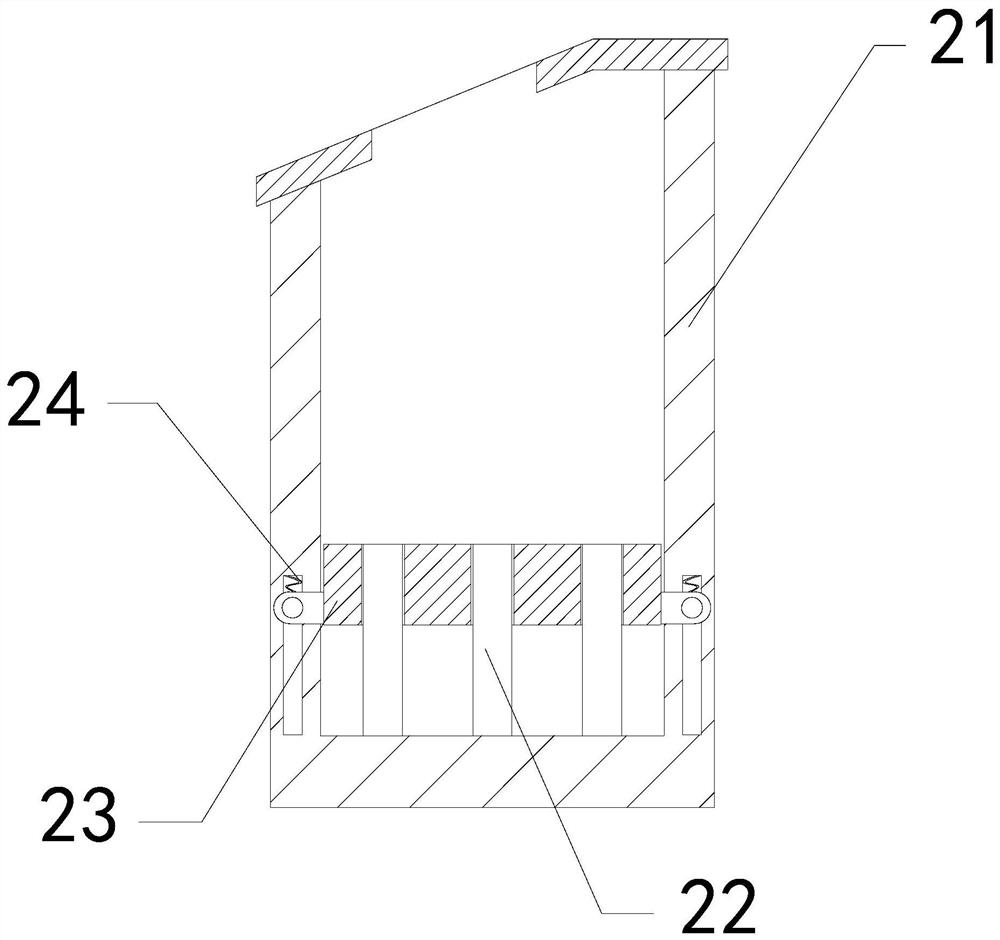

[0027] The invention provides a kind of solid-phase fermentation equipment for mixing food waste. Its structure includes a sealing cover 1, a body 2, and a control panel 3. 1 is an integrated structure; the body 2 includes an outer frame 21, a breaking mechanism 22, a shrinking plate 23, and a pull-back strip 24, and the bottom of the breaking mechanism 22 is embedded and connected to the bottom of the inner wall of the outer frame 21, and the breaking The loosening mechanism 22 is in clearance fit with the contraction plate 23 , the contraction plate 23 is movably engaged with the outer frame 21 , and the pullback strip 24 is installed between the contraction plate 23 and the inner wall of the outer frame 21 .

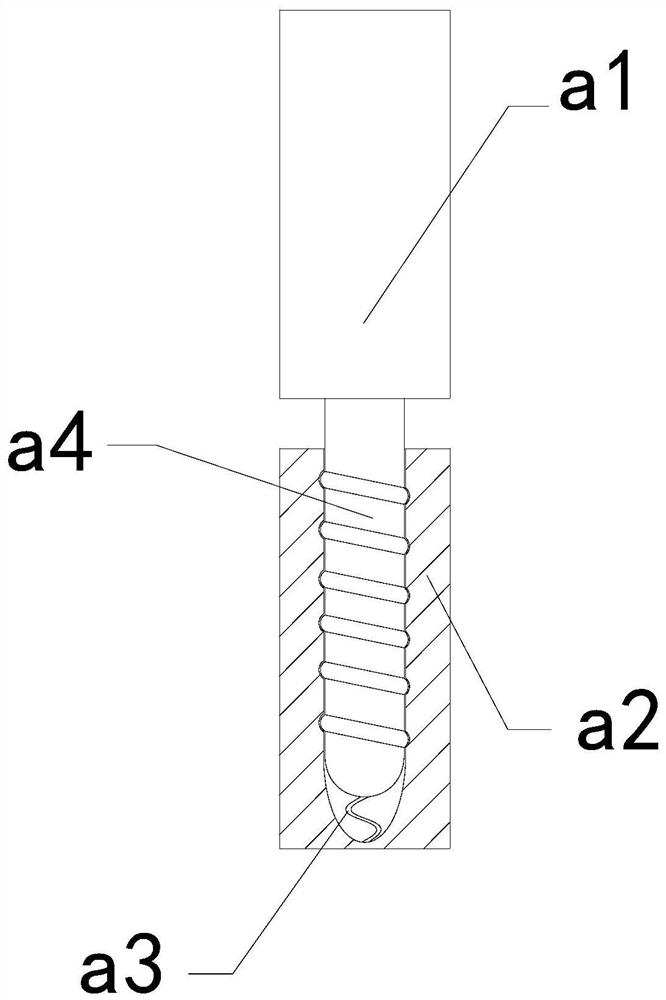

[0028] Wherein, the dispersing mechanism 22 includes a force plate a1, a sleeve frame a2, a reset bar a3, and a rotating rod a4, the force plate a1 is embedded in the upper end of the rotating rod a4, and the r...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] Wherein, the contraction plate 23 includes an upward stretching block c1, a plate surface c2, a transition block c3, and a joint block c4. The upward stretching block c1 is embedded in the upper end of the transition block c3. Movable engagement, the combination block c4 is installed on the side of the board surface c2, the said upward extension block c1 is provided with four, and two of them are evenly distributed symmetrically on the upper end of the board surface c2, through the mechanism upward The inertial force generated by the sliding reset can make the upward stretching block c1 stretch out upwards under the cooperation of the transition block c3.

[0036]Wherein, the upward extension block c1 includes an elastic strip c11, a receiving plate c12, and an outer swing plate c13. The elastic strip c11 is installed between the bottom of the outer swing plate c13 and the inner wall of the receiving plate c12. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com