Wire guide mechanism and medium-speed wire cutting machine comprising same

A technology of wire guide and wire guide nozzle, which is applied in the field of wire cutting machine tools, can solve problems such as vibration, increased processing costs, and cumbersome operation, and achieves the effects of reducing use cost, wide application range, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

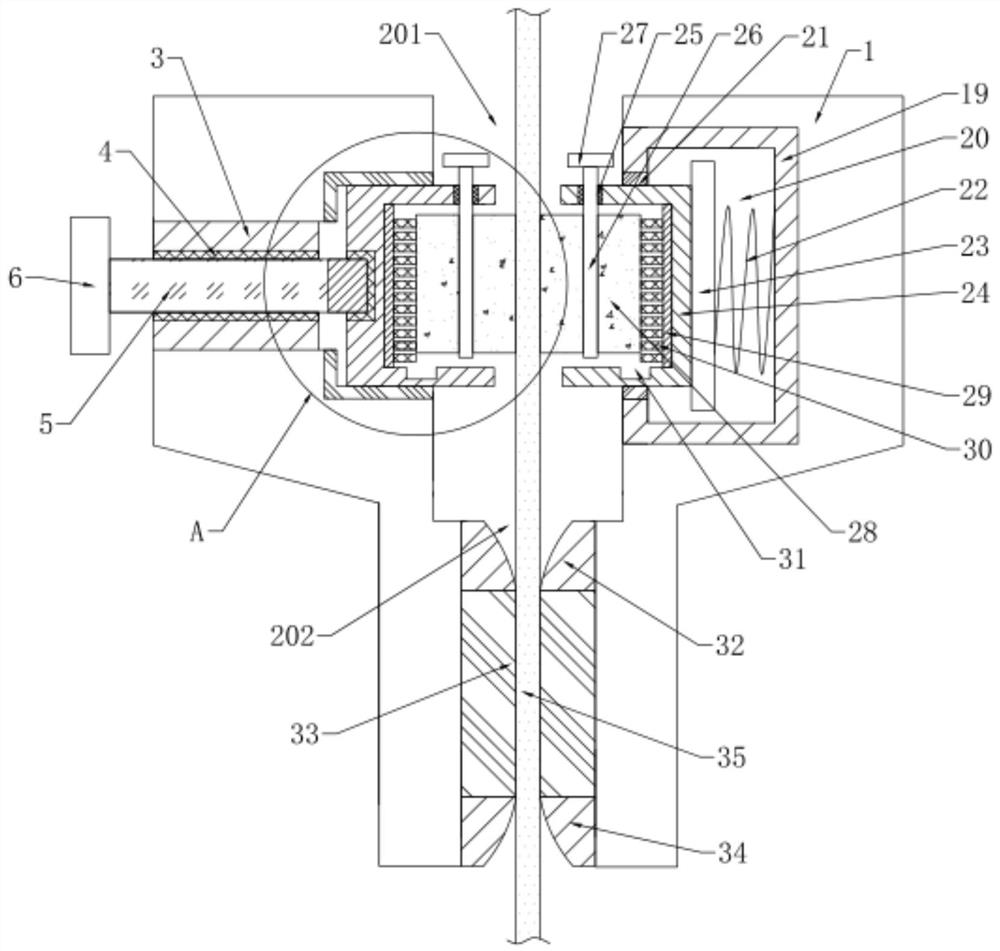

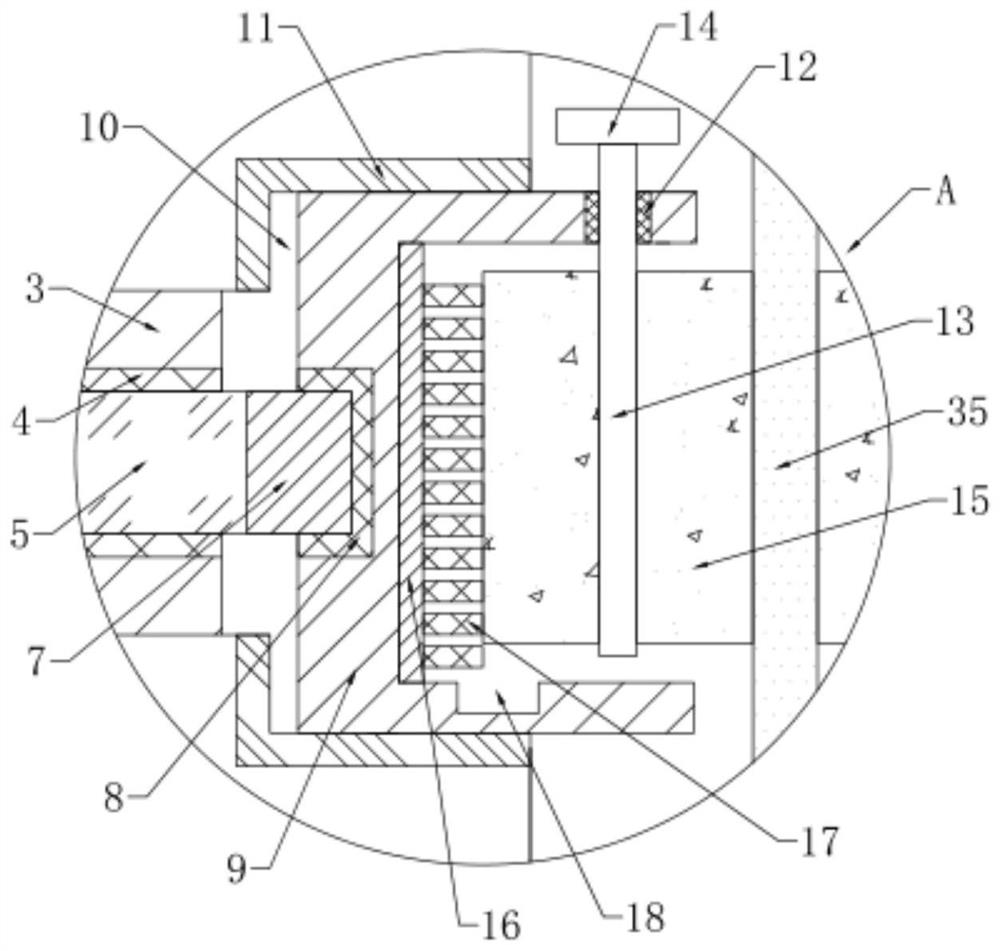

[0025] see Figure 1 to Figure 2 , the present invention provides a technical solution:

[0026] A wire guiding mechanism, comprising:

[0027] Nozzle main body 1, the first opening groove 201 and the second opening groove 202 connected to each other are opened in the wire guide main body 1, the inner diameter of the second opening groove 202 is smaller than the inner diameter of the first opening groove 201, close to the first opening A positioning rod 3 is embedded in the side wall of the guide wire main body 1 of the groove 201, and a threaded through groove 4 is provided in the positioned rod 3, and a threaded rod 5 is arranged on the threaded through groove 4, and the threaded rod 5 can be installed in the threaded through groove 4. Rotate in the slot 4, one end of the threaded rod 5 is fixedly provided with an adjustment handle 6, and one end of the threaded rod 5 away from the adjustment handle 6 is fixedly provided with a bottom post 7, the bottom post 7 is hingedly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com