Liquid nitrogen detection device and operation method thereof

A detection device, liquid nitrogen technology, applied in the direction of container filling method, container discharge method, gas/liquid distribution and storage, etc., can solve the problems of inconvenient operation, complex structure, large volume, etc., to improve the convenience of operation, The effect of reducing economic losses and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

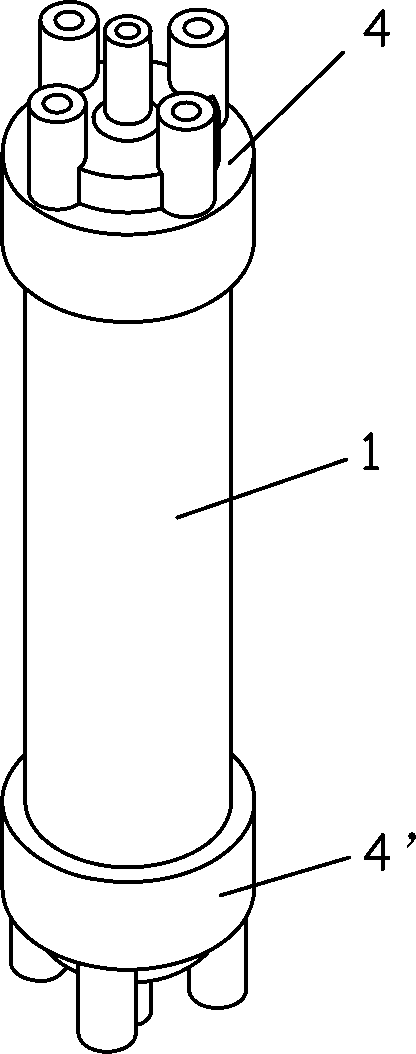

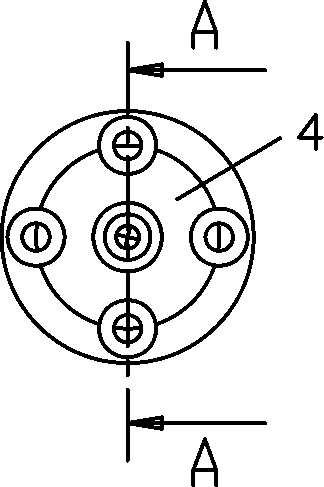

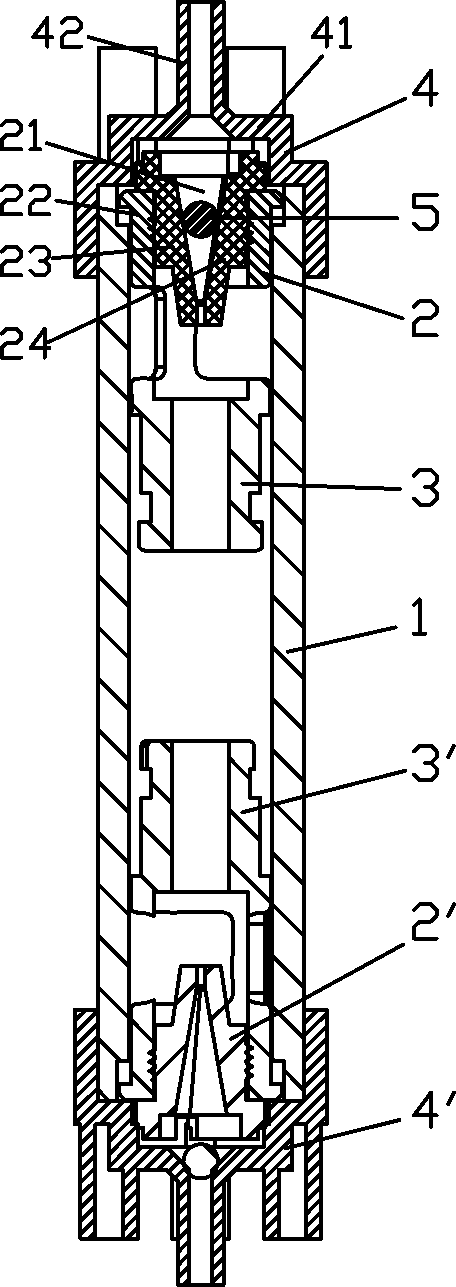

[0021] see Figure 1 to Figure 4 , the liquid nitrogen detection device of the present invention, it comprises:

[0022] Body 1, which is a pipe body, with steps 101 arranged circumferentially on the inner wall at the end;

[0023] The two conversion bodies 2, 2' are symmetrically inserted into the ports at both ends of the body 1, and the outer wall of the rear end is protrudingly provided with a step that can be fixed to the step 101 at the end of the body 1 (taking the conversion body 2 as an example, The same below), the conversion body 2 is provided with a conical central channel 21 along the axial direction, and the inlet diameter is larger than the outlet diameter;

[0024] Two detection sensing devices 3, 3' for detecting the number of air bubbles are arranged in the body 1, facing the outlet of the conversion body 2 in the body 1;

[0025] Two covers 4, 4', cover 4 (taking cover 4 as an example, the same below) includes a cover body 41 and a liquid nitrogen inlet an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com