Bottle interior and bottle body image single-station shooting equipment and corresponding detection equipment

A technology of image shooting and shooting equipment, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means. Detection and other issues, to achieve the effect of reducing detection time, reducing space occupation, and shortening the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

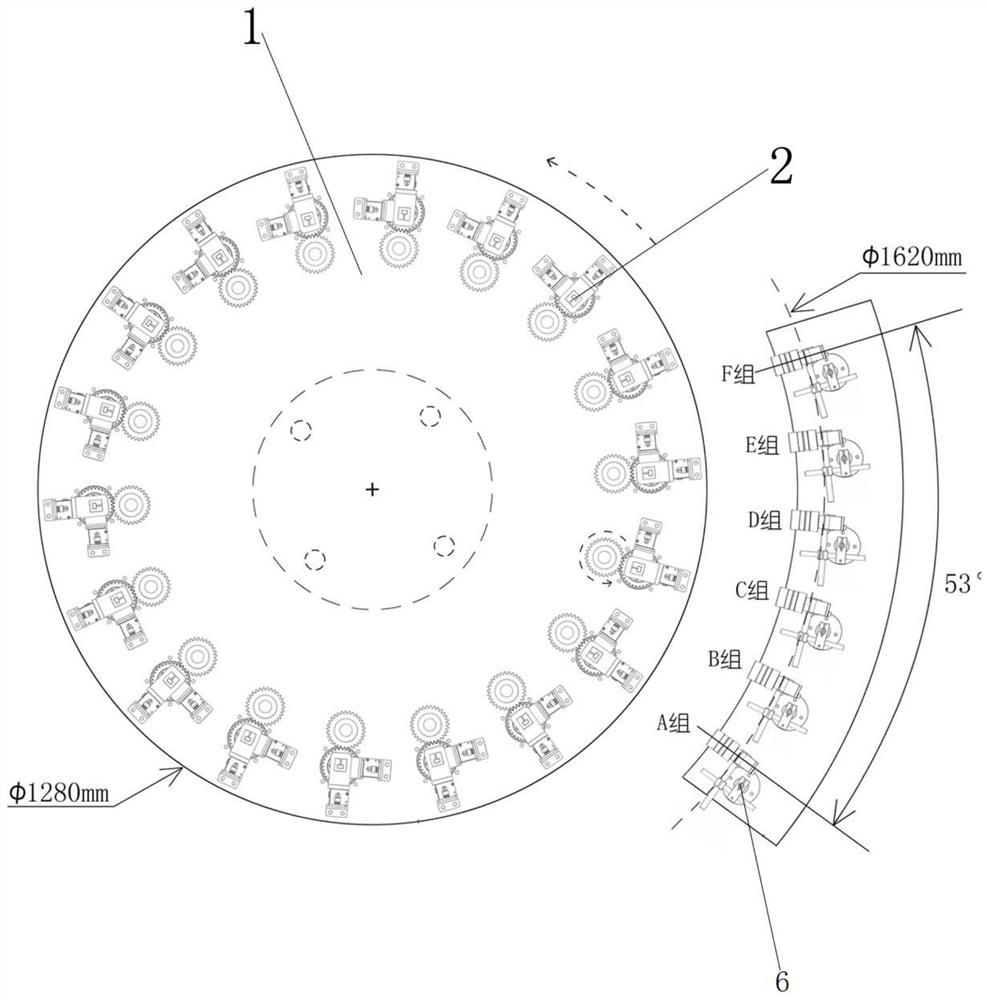

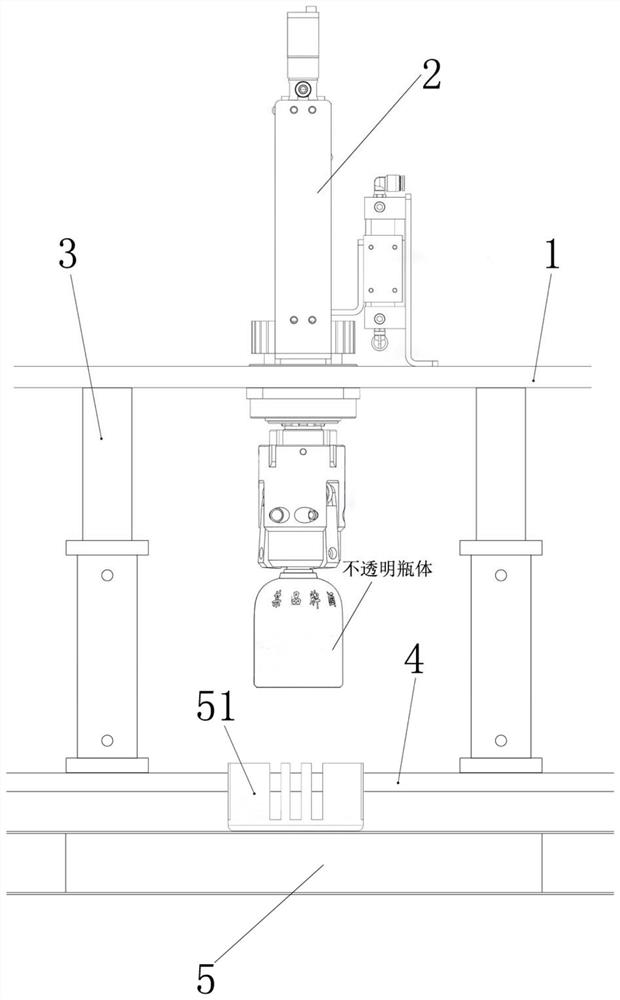

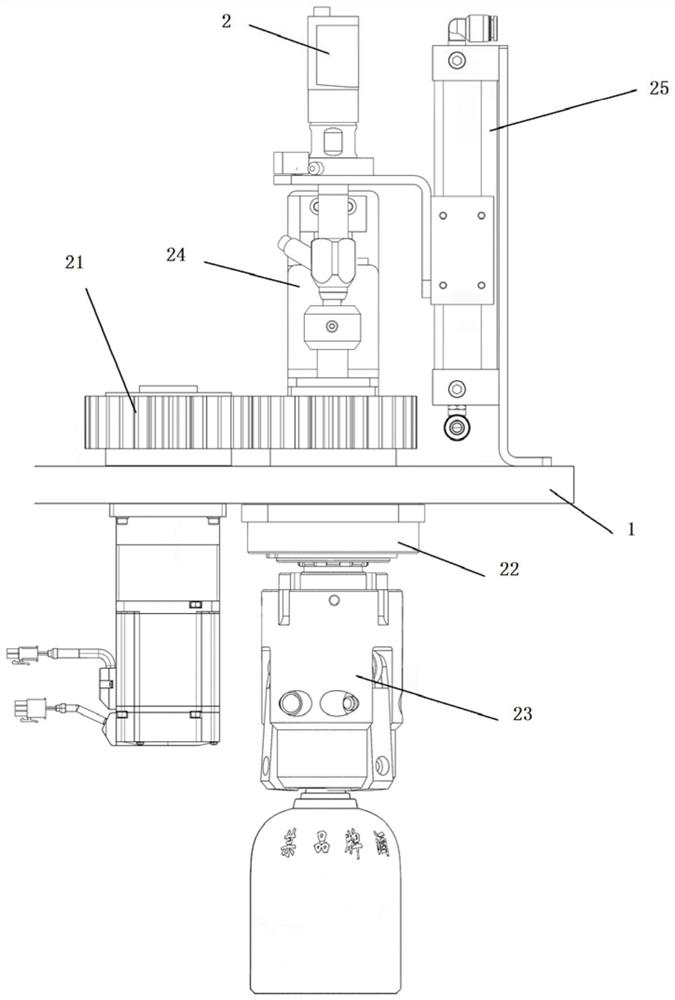

[0034] Refer to attached figure 1 , 2, 3, 4, 5, 9, the bottle and bottle body image single-station shooting equipment for opaque bottles in this embodiment includes a bottle body transport mechanism, at least one bottle image shooting assembly and at least one bottle body image Capture components. The bottle conveying mechanism comprises a steel rotating disk 1 and a plurality of bottle fixing mechanisms 2; the diameter of the steel rotating disk 1 is set as required, and there are n bottle fixing mechanisms 2 (the quantity can be adjusted as required, such as , can be between 4-30), n independent bottle fixing mechanisms 2 are evenly installed on the outer periphery of the steel rotating disc 1 in a ring array; the bottle fixing mechanism 2 includes a bottle clamp rotating assembly 22, a clamp bottle The bottle clamp 23 is connected with the bottle image capture assembly 25 and the bottle body image capture assembly 6. The bottle clamp 23 is fixedly sleeved on the bottle cl...

Embodiment 2

[0054] Based on Embodiment 1, this embodiment provides an image detection device for an opaque bottle body, including a single-station shooting device for the inside and body images of the opaque bottle body in Embodiment 1 and an image detection device, and the image detection device is compatible with the The internal and external industrial cameras of the single-station shooting equipment for the images inside the bottle and the body of the bottle are all connected by communication, and are used to detect foreign objects in the bottle based on the images captured by the industrial cameras; the corresponding image detection device can adopt the existing technology. For example, the existing image comparison module based on machine vision or other image detection devices based on convolutional neural network.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com