Multifunctional automatic nail extractor and assembling method thereof

A multi-functional and automatic technology, applied in nail pullers, manufacturing tools, etc., can solve the problems of limited use range and inconvenient use, and achieve the effect of simple structure, convenient nail removal, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

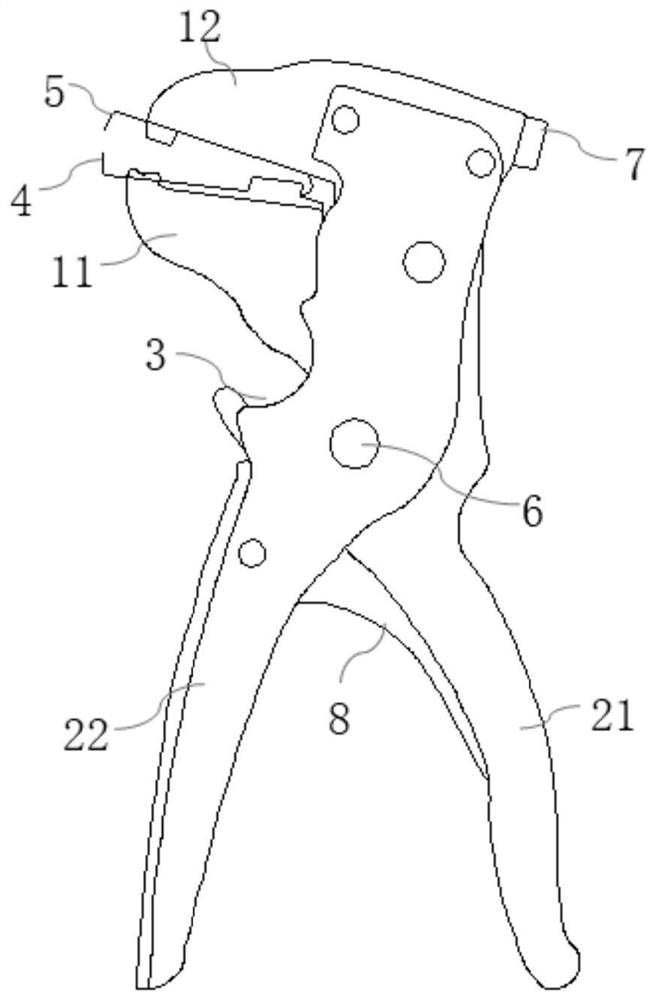

[0043] A kind of multifunctional automatic nail remover of the present embodiment, as figure 1 As shown, it includes a collet 1 and a handle 2. The collet 1 includes a movable collet 11 and a fixed collet 12. The fixed collet 12 is located above the movable collet 11 and is connected with the movable collet. 11 Turn to connect. The handle 2 includes a hand handle 22 and a shear handle 21, the hand handle 22 and the shear handle 21 are rotationally connected through the central shaft 6, and a return spring 8 is installed between the hand handle 22 and the shear handle 21; The hand handle 22 is fixedly connected with the fixed chuck 12 . When in use, the shearing handle 21 rotates around the central axis 6, thereby driving the movable chuck 11 to lift up and move toward the fixed chuck 12, so that the movable chuck 11 and the fixed chuck 12 are closed. After use, the return spring 8 is used to reset the movable chuck 11 to ensure that the movable chuck 11 and the fixed chuck 1...

Embodiment 2

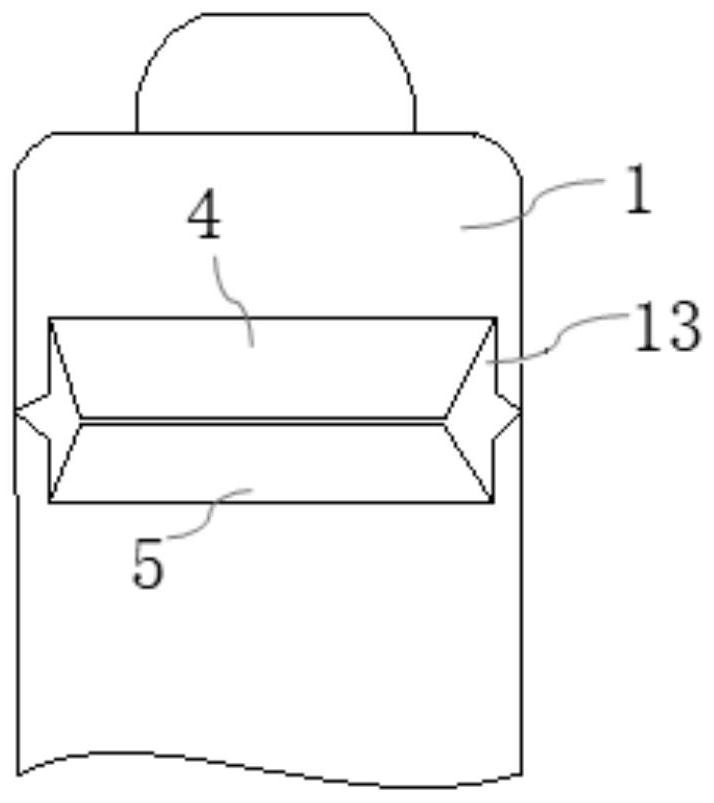

[0047] A kind of multifunctional automatic nail remover of the present embodiment, basic structure is the same as embodiment 1, difference and improvement are: as image 3 and Figure 4 As shown, in order to further clamp the nails, the shapes of the clamping ends of the upper clip 4 and the lower clip 5 of the multifunctional automatic nail remover of this embodiment match the shape of the nails to be extracted, and nails of various specifications can be removed. nail.

[0048] Such as image 3 As shown, the clamping ends of the upper clip 4 and the lower clip 5 are rectangular, which match the shape of the staple, and are convenient for pulling out the staple.

[0049] Due to the large cap of the thumbtack and the cylindrical body, such as Figure 4 As shown, the middle part of the upper clip 4 is provided with an arc-shaped groove I41, and the middle part of the lower clip 5 is provided with an arc-shaped groove II51; the centers of the arc-shaped groove I41 and the arc-...

Embodiment 3

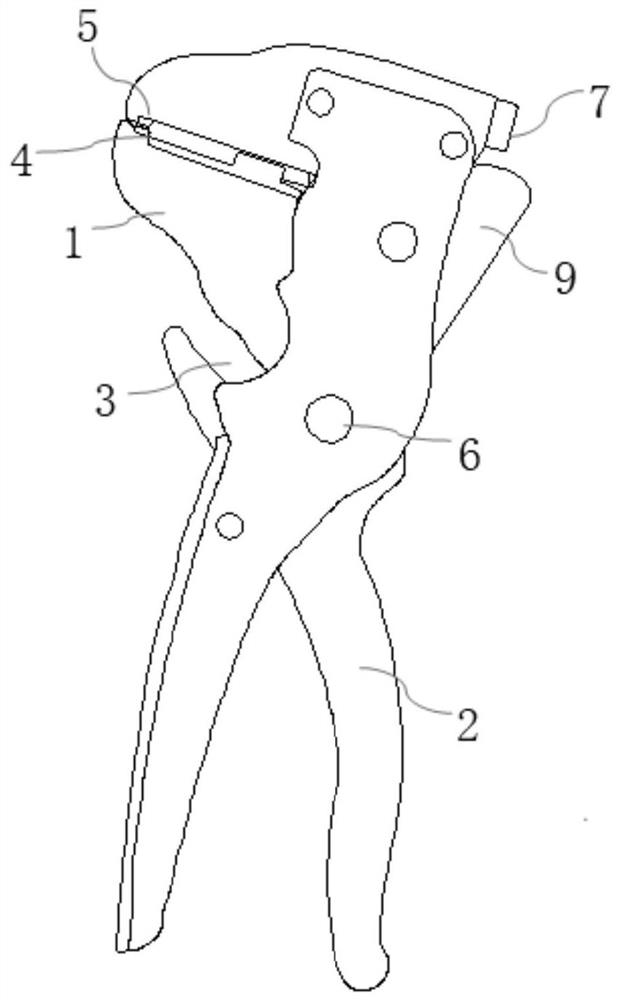

[0051] A kind of multifunctional automatic nail remover of the present embodiment, basic structure is the same as embodiment 1, difference and improvement are: as figure 1 and figure 2 As shown, an adjustment knob 7 is installed on the fixed chuck 12 to adjust the clamping force of the upper clip 4 and the lower clip 5, and adjust according to the difficulty of pulling out, so that nails of various specifications can be removed. nail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com