Rubber internal mixer device with adjustable base

A rubber banburying and adjustable technology, applied in the field of banburying machines, can solve problems such as troublesome operation, inclination of the body, troublesome adjustment, etc., and achieve the effects of easy operation, good buffer protection, and safety performance guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

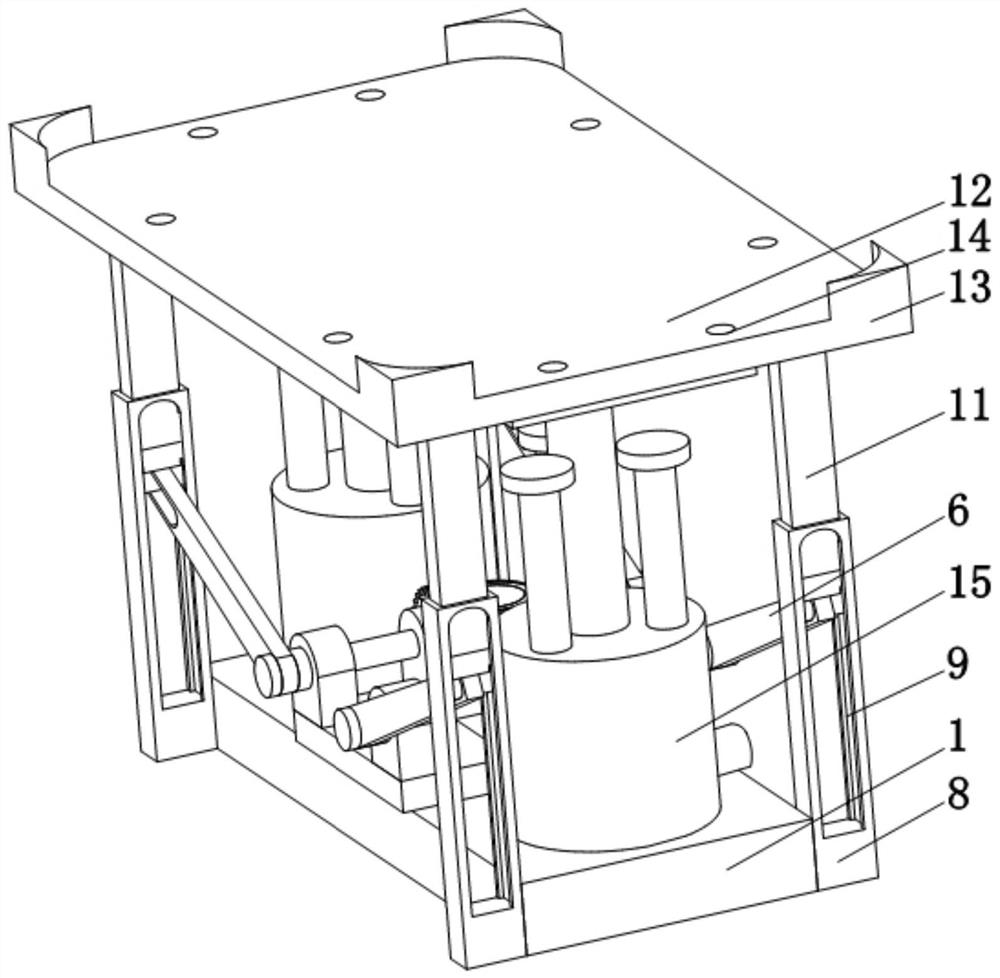

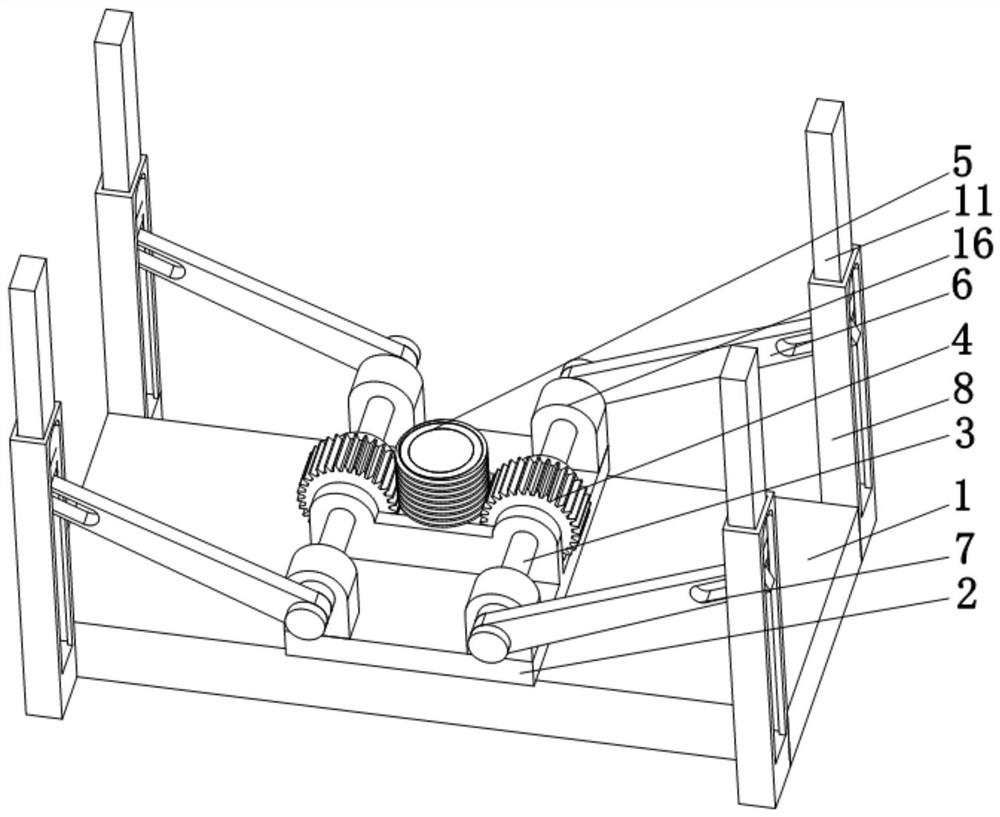

[0027] Such as Figure 1 to Figure 5As shown, the present invention provides a rubber internal mixer material box 17 with an adjustable base, including a base 1, characterized in that a console 2 is provided at the center of the top of the base 1, and support blocks 16 are provided at the four corners of the top of the console 2 , the four support blocks 16 have the same shape and size, and are distributed in an array with respect to the middle part of the console 2. A driving rod 3 is connected between the two support blocks 16 through bearing rotation. The middle part of the driving rod 3 is provided with a gear 4, and the two gears 4 The shape and size are the same and the number of modulus teeth is the same. A worm device 5 is provided at the center of the top of the console 2. The worm device 5 meshes with the gears 4 at both ends. Both ends of the driving rod 3 are provided with control rods 6. The horizontal angles are the same, so the rotation of the worm device 5 will...

no. 2 example

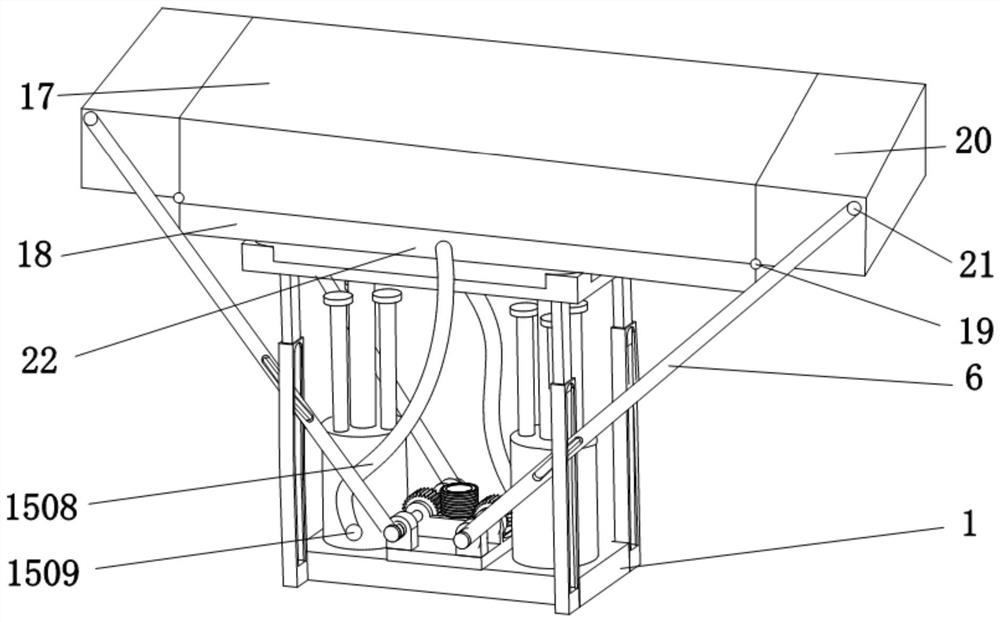

[0031] Based on the rubber mixer device with an adjustable base provided in the first embodiment, the material box 17 of the mixer can not only be lifted and lowered by lifting the pallet 12 of the mixer, but also needs to be lowered to the lowest point. The processed rubber is taken out, and the processed rubber needs to be added again, but when the device is lowered to the lowest point, the operator still needs to pick and place the rubber inside the material box 17 of the internal mixer, and even needs to use tools, so a lot of manual work is required. Auxiliary work reduces the processing efficiency and increases the processing cost. In order to solve this problem, combined with Figure 6 , the rubber mixer device with an adjustable base also includes: an elastic bottom plate 18 is provided at the inner bottom of the material box 17 of the internal mixer, and a cavity 22 is provided at the center of the elastic bottom plate 18. The elastic bottom plate 18 has a certain elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com