Steel wire rope winding device for construction site and using method of steel wire rope winding device

A construction site and winding device technology, which is applied in the field of wire rope winding, can solve the problems of loose wire rope, easy falling off, uneven winding, etc., and achieve the effects of tight winding, increased walking time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

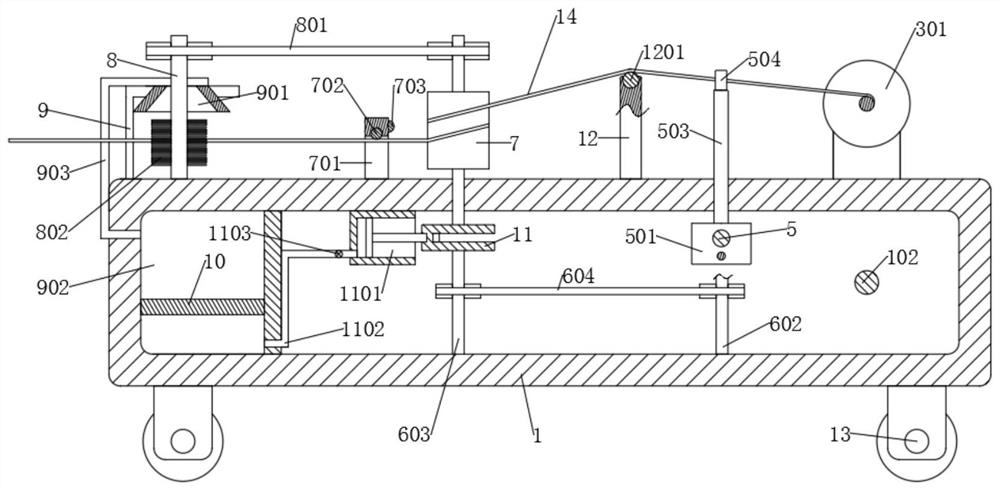

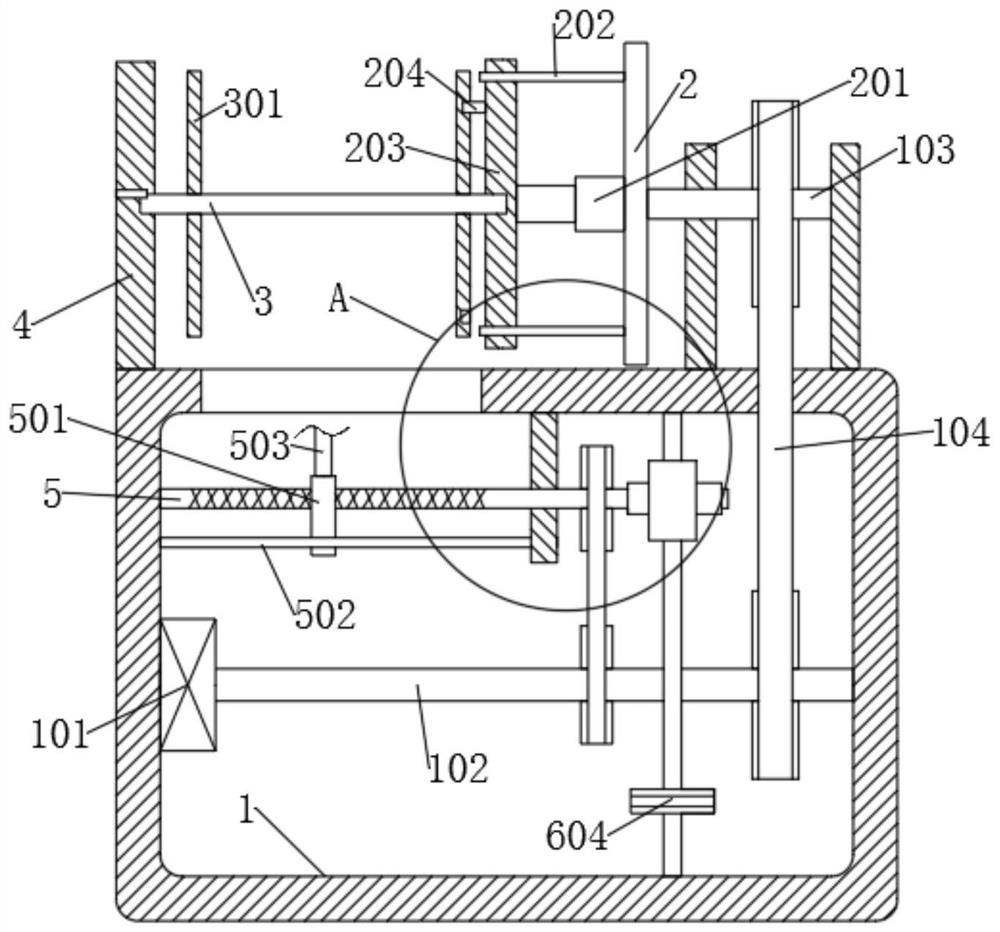

[0036] refer to Figure 1-4 , a wire rope winding device for a construction site, comprising a box body 1 and a wire rope body 14, a motor 101 is arranged in the box body 1, a first rotating shaft 102 is connected to the output end of the motor 101, and a winding mechanism is provided on the box body 1 , the winding mechanism is connected to the first rotating shaft 102 through the first belt 104, and the fourth rotating shaft 603 is rotatably connected to the box body 1. The fourth rotating shaft 603 is provided with a fastening cylinder 7, and the fastening cylinder 7 and the wire rope body 14 Correspondingly, the box body 1 is provided with a reciprocating mechanism, the reciprocating mechanism is fixedly connected with a reciprocating rod 503 , and the reciprocating rod 503 is fixedly connected with a circular ring 504 , and the wire rope body 14 runs through the circular ring 504 .

[0037] The winding mechanism includes a cylinder 201 and a winding shaft 3. The casing 1 ...

Embodiment 2

[0047] refer to Figure 1-4 , a wire rope winding device for a construction site, comprising a box body 1 and a wire rope body 14, a motor 101 is arranged in the box body 1, a first rotating shaft 102 is connected to the output end of the motor 101, and a winding mechanism is provided on the box body 1 , the winding mechanism is connected to the first rotating shaft 102 through the first belt 104, and the fourth rotating shaft 603 is rotatably connected to the box body 1. The fourth rotating shaft 603 is provided with a fastening cylinder 7, and the fastening cylinder 7 and the wire rope body 14 Correspondingly, the box body 1 is provided with a reciprocating mechanism, the reciprocating mechanism is fixedly connected with a reciprocating rod 503 , and the reciprocating rod 503 is fixedly connected with a circular ring 504 , and the wire rope body 14 runs through the circular ring 504 .

[0048] The winding mechanism includes a cylinder 201 and a winding shaft 3. The casing 1 ...

Embodiment 3

[0059] A method for using a wire rope winding device for a construction site, the following steps are used:

[0060] S1, place the reel 3 in the sliding groove 401, start the cylinder 201, insert the fixed tooth 204 into the groove 302, and insert the positioning pin 402;

[0061] S2, wind the steel wire rope body 14 on the fastening cylinder 7, and then pass through the ring 504 and fix it on the reel 3;

[0062] S3, start the motor 101, and the motor 101 drives the first rotating shaft 102 to rotate;

[0063] S4, the first rotating shaft 102 drives the reel 3 to rotate through the first belt 104, and winds the wire rope body 14 on the reel 3;

[0064] S5, the first rotating shaft 102 drives the two-way screw 5 to rotate through the fourth belt 505, drives the ring 504 to move back and forth through the reciprocating mechanism, and the ring 504 drives the wire rope body 14 to move back and forth, and is evenly wound on the reel 3;

[0065] S6, the two-way screw 5 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com