Steel structure wall for industrial and civil buildings

A technology for civil buildings and steel structures, applied in building components, building structures, buildings, etc., can solve the problems of inconvenient wall disassembly, inability to adjust the position of the inner wall of steel structure walls, etc., and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

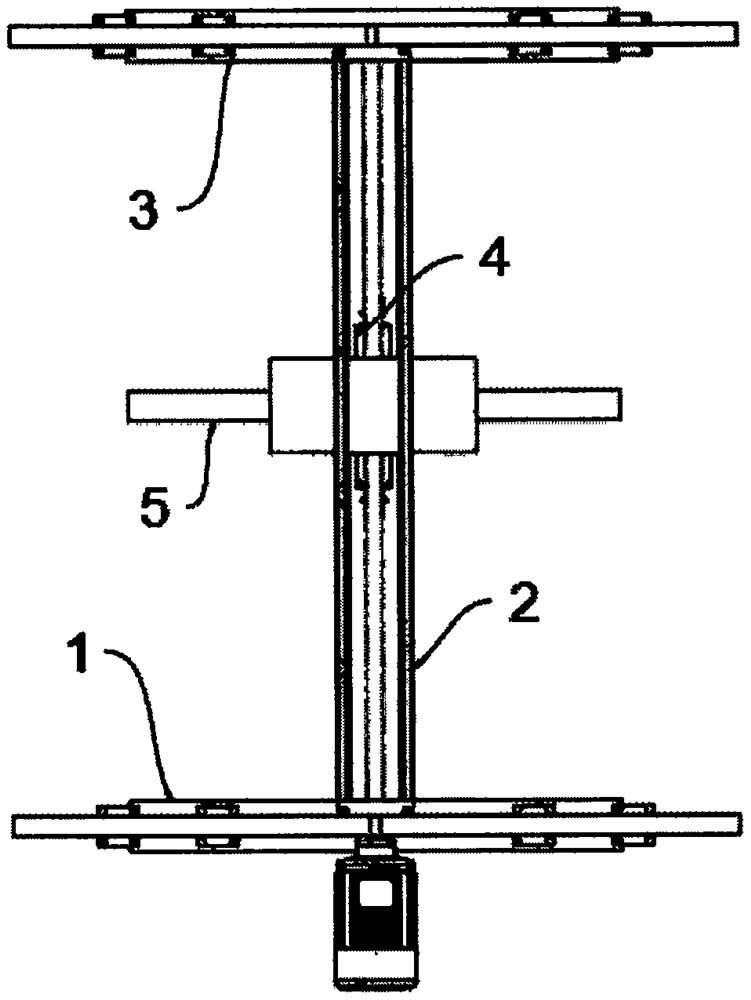

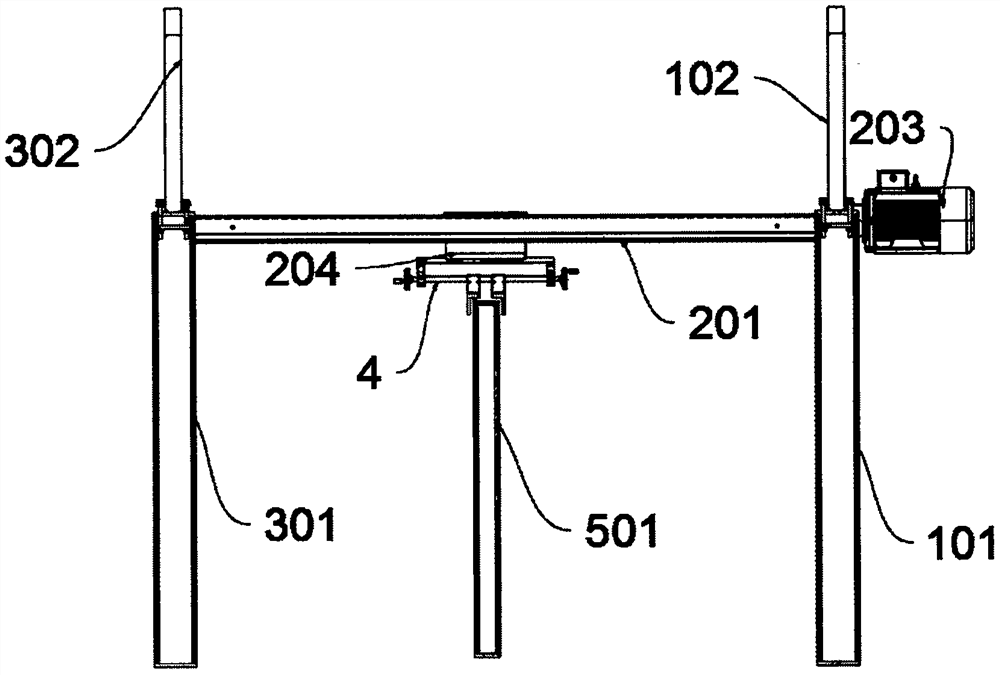

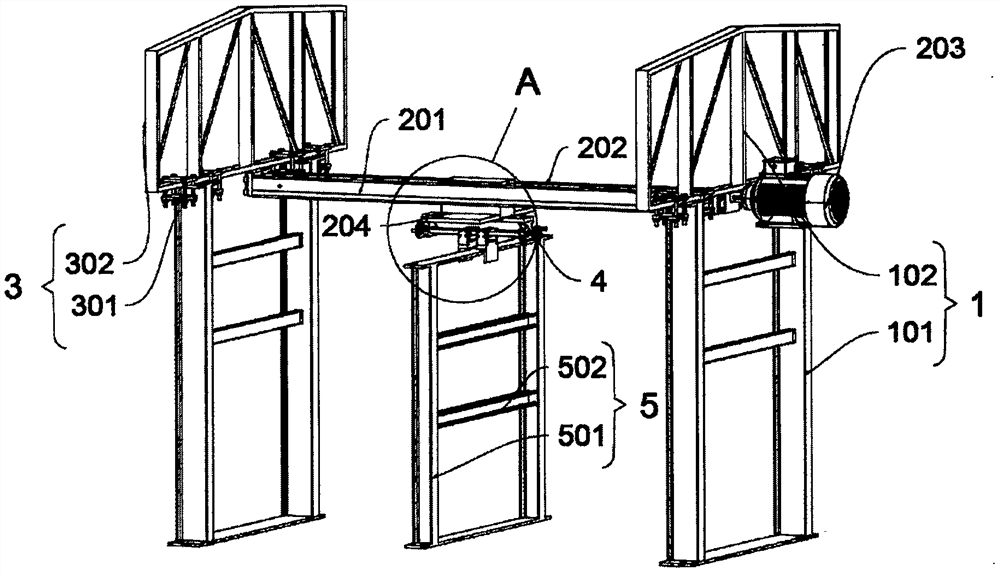

[0030] as attached figure 1 to attach Figure 6 Shown:

[0031] The present invention provides a steel structure wall for industrial and civil buildings, including: a first support mechanism 1 and a fixing mechanism 4, the position above the middle of the rear end of the first support mechanism 1 is fixedly connected with the front end of the transmission mechanism 2; the transmission mechanism 2. The rear end is fixedly connected to the upper middle of the front end of the second supporting mechanism 3; the fixing mechanism 4 is slidably connected to the position below the transmission mechanism 2; the fixing mechanism 4 includes a limit frame 401, a rotating rod 402 and a splint 403, and the bottom of the limit frame 401 is front and rear Both ends are rotatably connected with a rotating rod 402, and two splints 403 are slidably connected to the position below the limit frame 401 through the cooperation of the two rotating rods 402; the bottom of the fixing mechanism 4 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com