Perforation charge explosion method suitable for shear wall in blasting demolition

A shear wall and charge technology, applied in blasting and other directions, can solve the problems of large impact range, large amount of explosives used, waste of resources and manpower, etc., and achieve the effects of saving manpower, material and financial resources, controlling harmful effects, and precise blasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] A kind of perforation charge explosion method applicable to shear walls in blasting demolition of the present invention comprises the following steps:

[0102] (1) divide the body of wall in the building that needs to be removed, described body of wall is divided into common body of wall and shear wall; Described shear wall is divided into large size shear wall and normal size shear wall;

[0103] (2) the perforation charging method of described large-scale shear wall comprises the steps:

[0104] S1, excavate the arched wall hole in the shear wall;

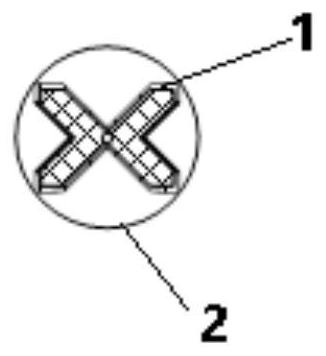

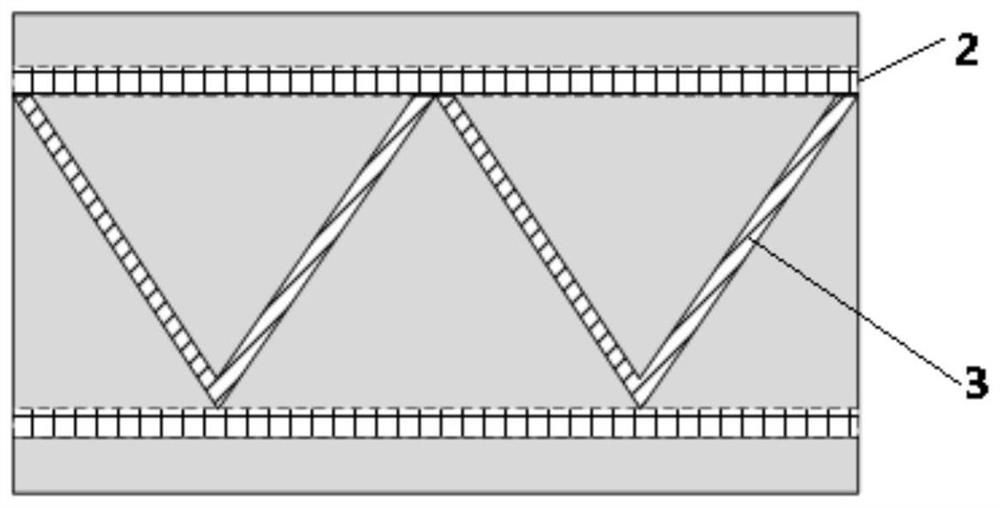

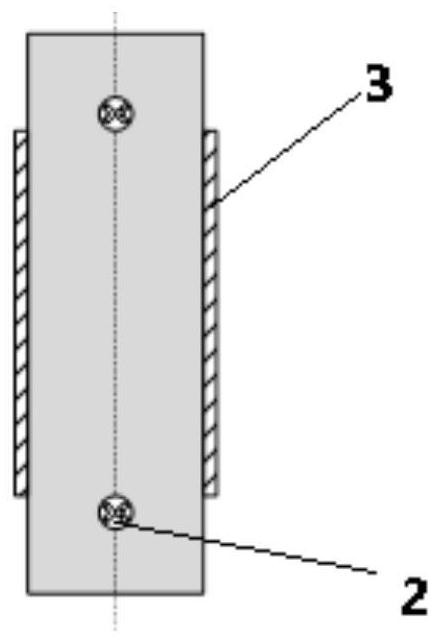

[0105] S2. Set two through holes on the top and bottom of the shear wall. The top hole is 0.5m away from the upper floor, and the bottom hole is 0.5m away from the lower floor. X-shaped energy-concentrating cutters are installed in the top hole and the bottom hole ;

[0106] S3. There is a set of horizontal tunnels between the top tunnel and the bottom tunnel, a part of the horizontal tunnels enter from the left wall, an...

Embodiment 2

[0123] A method for demolishing a super high-rise building, comprising the steps of:

[0124] Step 1. Set up the peripheral working platform of the building: build a convenient safety protection frame with a height of four floors and can move up and down on the periphery of the super high-rise building, mainly composed of steel pipes, baffles, protective nets, lifting equipment, etc.;

[0125] Step 2. Pre-demolition: Take every two floors as a demolition unit, divide it into the first demolition unit and the second demolition unit from top to bottom, and so on until reaching the first floor of the building; then pre-demolition of the first demolition unit For demolition, according to the principle of well-shaped, some columns in the inner layer of the symmetrical reserved frame will not be blasted to ensure the overall stability of the building during the blasting process.

[0126] Step 3, perforating charge: Divide the first demolition unit into a blasting area and a static c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com